Rolled Prepainted Steel Coil Z75 for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

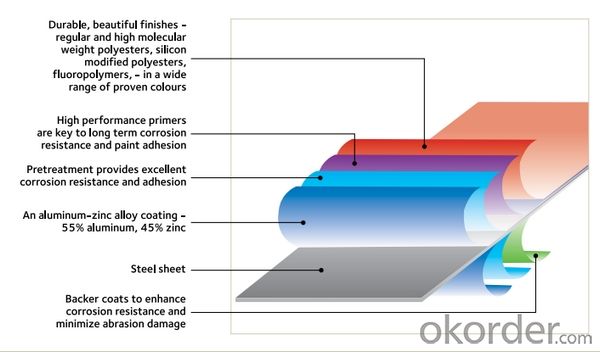

Structure of Rolled Prepainted Steel Coil Z75 for Construction

Description of BMT Rolled Prepainted Steel Coil for Construction

BMT Prepainted Rolled Steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Zn coating on both faces by hot dip process. Its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Rolled Prepainted Steel Coil Z75 for Construction

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

3. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Rolled Prepainted Steel Coil Z75 for Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel

2. Electric appliance: refrigerator; washing machine; refrigerator..

3. Transportation: oil tank; road sign; etc.

4. Agriculture:barn; etc.

5. Others: vending machine; game machine; etc.

Specifications of Rolled Prepainted Steel Coil Z75 for Construction

Product | BMT Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+Z/DX51D+AZ etc |

Thickness | 0.3-3.5mm |

Width | 600-1250mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z50-150g/m2 |

Technique | Raw material: Hot rolled steel coil > Cold rolled>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 610MM |

Coil weight | 3-15MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Rolled Prepainted Steel Coil Z75 for Construction

We have organized several common questions for our clients,may help you sincerely:

1. What is your guarantee against colour fading?These products can be customized according to your requirement, including zinc coating,

printing color, roll width, etc.

2. What is the general delivery time?

Usually it is within thirty working days after received buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 20- 25 days, but the shipment will depend on the vessel situation.

3. How do you promise the quality of the steels?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are steel coils inspected for uniformity using statistical analysis?

- Steel coils are inspected for uniformity using statistical analysis by randomly selecting a sample of coils and measuring specific characteristics such as thickness, width, and weight. These measurements are then analyzed using statistical methods, such as mean, standard deviation, and control charts, to determine if the coils meet the desired uniformity criteria. This approach allows for efficient and reliable assessment of the overall quality and consistency of steel coils.

- Q: What are the different types of surface defects in steel coils?

- Some common types of surface defects in steel coils include scratches, pits, rust, scaling, laminations, and waviness.

- Q: How do you calculate the weight of a steel coil?

- To calculate the weight of a steel coil, you need to know the dimensions of the coil, specifically its length, width, and thickness. Then, you can use the density of steel (usually around 7850 kg/m³) and the formula: weight = length x width x thickness x density.

- Q: I want to experiment with making steel and want to especially make it stronger. And also I want to know if its possible to turn a meteorite into steel?

- To add to Alex's good answer... ASM Intl now has a book titled Steel Metallurgy for Non-Metallurgist. You can turn metallic meteorites into steel if you add the right amount of Fe and C. That won't make it the strongest but it is possible. I don't think you want the strongest exactly. In general and with swords in particular, you want to be pretty specific about exactly what physical properties you want. Strength and ductility typically vary inversely to each other, higher stength, lower ductility, or lower strength, higher ductility. The issue is related to the idea of a diamond sword. It would be nice and hard but it would probably shatter the first time you stuck anything with it. Swords need a combination of properties, hard so it holds a sharp edge, and tough so it does not fracture, strong so it can be light enough to swing.

- Q: How are steel coils processed and treated?

- To ensure the quality and suitability of steel coils for different applications, they undergo a series of steps and treatments. Initially, the coil is uncoiled by removing its protective wrapping and unwinding it. Any defects like cracks or uneven surfaces are then inspected. Next, the coil is cleaned to eliminate dirt, oil, and rust using chemical agents and mechanical scrubbing. After cleaning, it is rinsed and dried to prevent corrosion caused by residual moisture. Once cleaned, the steel coil may be treated based on its intended use. One common treatment is pickling, where the coil is immersed in an acidic solution to remove impurities and scale. This improves the surface finish and prepares the steel for further processing. After pickling, the coil can undergo cold rolling, which reduces its thickness and improves dimensional accuracy. This is done by passing the steel through a series of rollers at room temperature, gradually decreasing thickness and increasing strength. It also improves the surface finish. In some cases, the coil may undergo additional heat treatments like annealing or tempering. Annealing involves heating the coil to a specific temperature and slowly cooling it to relieve internal stresses and improve mechanical properties. Tempering, on the other hand, involves reheating the coil to a lower temperature and rapidly cooling it to enhance strength and toughness. Once the desired processing and treatments are completed, the steel coil may be coated or painted for added protection against corrosion or to enhance its appearance. Coating processes can include hot-dip galvanizing, electroplating, or applying organic coatings like paint or powder coatings. Finally, the processed and treated steel coils are cut into specific sizes or shapes according to customer requirements. This can be done using cutting methods such as shearing, slitting, or sawing. Overall, the processing and treatment of steel coils involve cleaning, pickling, rolling, heat treatment, coating, and cutting processes. These steps are carefully carried out to ensure the quality, strength, and suitability of the steel for its intended applications.

- Q: steel bollard poles?

- They're short steel posts that are used as a barrier to keep traffic out of an area. If you want to see an example Google it and look at the pics.

- Q: Can steel coils be coated with nickel?

- Yes, steel coils can be coated with nickel.

- Q: Can we construct a barn using steel and will it be a durable one?

- Barns can be constructed out of a number of materials be it steel, block or wood. Among all the available materials, steel offers the best in terms of strength, durability and pricing. Constructing a barn using wood can be a costly task because of the high price of wood. On the other hand, constructing a barn using block consumes more time and involves a much more professional approach thereby increasing the labor costs. Considering all these factors, it is always recommended to go for steel barns due to their durability, robustness and longer life span.

- Q: I need steel toe shoes for a workplace, where can I get them?I live in Surrey,UK.

- by on the internet or ppe clothing shops

- Q: Search the internet for 'Frost Clipper Knife'. This knife comes in either stainless or carbon steel. I have a friend who has one (stainless steel) and he is very impressed with it, but I have heard that Carbon Steel blades are better? Discuss...

- If your talking about a folding pocket knife, I think that it's basically six one way and a half dozen the other. I actually do prefer stainless for my pocket knives. I don't want to oil a knife to the degree I feel carbon requires, only to then stick it my pocket to attract dirt to the knife and oil to my pants. I'm the exact opposite on sheath knives though. I like 1095 carbon steel, plain edge sheath knives. I'll thrash on them HARD, and I rarely have major edge problems. Of course, I require them to be coated with some kind of powder coat or the like, because they can rust, but I do try and keep them clean and dry when in the sheath, so they won't pit the uncoated edge. My reasons for this sheath knife preference is multi-fold. First, these knives are simply affordable. I don't spend $80 dollars on a outdoors sheath knife. I use the tool too hard to want to spend more. I don't like the more traditional stainless steels such as AUS-8, 420HC, and 440C (not to mention the HORRENDOUS 440A) because I feel that the all else being equal, a stainless blade will bend before a carbon blade will break. I also think that carbon holds an edge at least as well, if not better, than traditional stainless, and it's much easier to hone. I don't know much about these new laminates, other than the very hard, but not so tough. They seem to be POSSIBLY too brittle for my use. That, combined with the fact that they cost a FORTUNE, means that I just won't be considering them.

Send your message to us

Rolled Prepainted Steel Coil Z75 for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords