Rolled Aluminum Coil for Aluminum Roofing Coated Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Coated Sheet for Aluminium Roofing Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Coated Sheet for Aluminium Roofing:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Coated Sheet for Aluminium Roofing:

Aluminium Coated Sheet for Aluminium Roofing Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

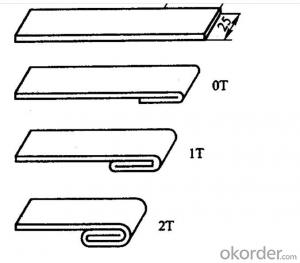

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum coils be used in the production of heat exchanger fins?

- Indeed, aluminum coils have the capability to be employed in the manufacturing process of heat exchanger fins. The utilization of aluminum as a material for heat exchanger fins is quite prevalent owing to its exceptional thermal conductivity, lightweight composition, and resistance against corrosion. These attributes render it a perfect substance for the efficient transfer of heat, ensuring both sturdiness and long-lasting performance. The ease with which aluminum coils can be shaped into intricate fin designs further enhances the surface area available for heat exchange. Moreover, the abundant availability and cost-effectiveness of aluminum make it the favored selection for the production of heat exchanger fins across a multitude of industries, including HVAC, automotive, and refrigeration.

- Q: Are aluminum coils suitable for high-strength applications?

- No, aluminum coils are not typically suitable for high-strength applications. Aluminum has lower tensile strength compared to other metals like steel, making it less ideal for high-stress or heavy-duty applications where strength is a critical factor.

- Q: What is the typical price gap between purchasing new aluminum coils versus used ones?

- <p>The price difference between new and used aluminum coils can vary significantly based on factors such as the quality of the used coils, market demand, and the specific grade of aluminum. On average, used aluminum coils can be 20-50% cheaper than new ones. However, this is a broad estimate and actual prices can fluctuate. It's essential to check current market prices and consider the condition of the used coils before making a purchase decision.</p>

- Q: Can aluminum coils be used in solar panel manufacturing?

- Yes, aluminum coils can be used in solar panel manufacturing. Aluminum is a lightweight and durable material that is commonly used in various industries, including the solar panel manufacturing industry. It is often chosen for its excellent thermal conductivity, corrosion resistance, and cost-effectiveness. Aluminum coils are typically used in the production of solar panels to create the frame or support structure for the photovoltaic cells. The coils are fabricated and shaped into the desired form, providing a strong and stable structure for the solar panel. Additionally, aluminum is also recyclable, making it an environmentally friendly choice for solar panel manufacturing.

- Q: Why the aluminum sheet crack after?

- What I want to add is to choose such welding wires as 5383 or 5183 wire whose magnesium content is higher than 5754 wire. The loss of magnesium due to high temperature in welding process may reduce the intensity of welding area.

- Q: i have some questions about aluminum can recycling??:how much can you get from doing that??where can i take them in indianapolis, in???and what else could i recycle??its good for the earth and i need some money!! :) :D thanks!!! :)

- Aluminum is not biodegradable. Also making aluminum from ore requires a lot of energy. Recycling cans is easy and saves a whole lot of energy reducing green house gases. Recycling aluminum also reduces the mining required to dig up aluminum ore thereby saving the land and stopping pollution from mine run-off.

- Q: Explain the distinction between aluminum coil and copper coil, highlighting their properties and uses.

- <p>Aluminum coil and copper coil are both metal coils used in various industries, but they have distinct properties. Aluminum coil is lighter, more corrosion-resistant, and less expensive than copper coil. It is often used in applications where weight and cost are concerns, such as in construction and electrical wiring. Copper coil, on the other hand, has superior electrical conductivity and is more ductile, making it ideal for electrical applications where high conductivity is required, such as in power transmission cables and wiring for electronics. Copper is also used in plumbing due to its resistance to corrosion. In summary, the choice between aluminum and copper coil depends on the specific requirements of the application, including factors like conductivity, weight, cost, and resistance to corrosion.</p>

- Q: Are aluminum coils resistant to UV rays?

- Yes, aluminum coils are resistant to UV rays.

- Q: Is it possible to use aluminum coils in the construction of a solar charger or battery pack?

- <p>While aluminum coils can be used in various electrical applications due to their conductivity, they are not typically used in solar chargers or battery packs. Solar chargers and battery packs usually require materials with higher conductivity and specific properties for efficient energy transfer and storage. Copper is more commonly used for wiring in these devices due to its superior conductivity compared to aluminum. Aluminum may not provide the necessary efficiency and could lead to energy loss. For the best performance in solar chargers and battery packs, it's recommended to use materials specifically designed for these applications, such as high-quality copper wiring and appropriate battery cells.</p>

- Q: im doing an a level physics presentation on aluminium and im trying to compare aluminium and copper in electricity pylons.i know that copper will have a better conductance than aluminium becasue it has a lower resitivity but i need to come up with a calculation to prove why aluminium is better for use in electricity pylons? i know its down to aluminium being more lightweight than copper and also much cheaper. But im not sure how to create an calculation to show this?:) any help is greatly appreciated

- Copper has lower resistance per unit volume, ie, a 1 cm diameter copper wire has less resistance than a 1 cm aluminum wire. BUT, aluminum is much lighter than Cu for the same diameter. If you used an aluminum wire that weighs the same as the 1 cm diameter copper wire, it would have LOWER resistance. And that is why aluminum is used in power transmission, and also in aircraft, where weight is important. to do this you calculate density resistivity which is (resistivity x density). Here is a partial table: Al 28.2e-9 Ω-m * 2700 kg/m? = 76e-6 Ω-kg/m? Cu 17.2e-9 Ω-m * 8960 kg/m? = 154e-6 Ω-kg/m? Ag 15.9e-9 Ω-m * 10500 kg/m? = 167e-6 Ω-kg/m? Au 22.14e-9 Ω-m * 19300 kg/m? = 427e-6 Ω-kg/m? Zn 68e-9 Ω-m * 7130 kg/m? = 485-6 Ω-kg/m? Fe 100e-9 Ω-m * 7870 kg/m? = 787e-6 Ω-kg/m? Note that Al is half that of Cu.

Send your message to us

Rolled Aluminum Coil for Aluminum Roofing Coated Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords