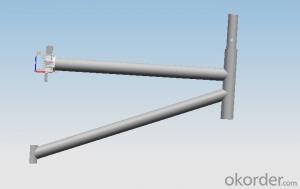

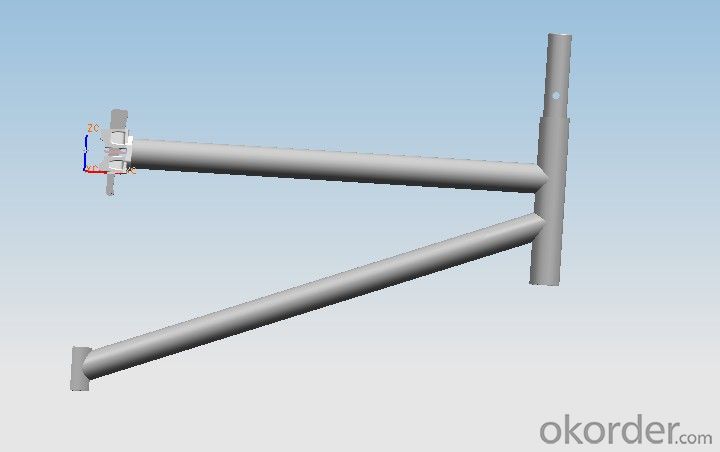

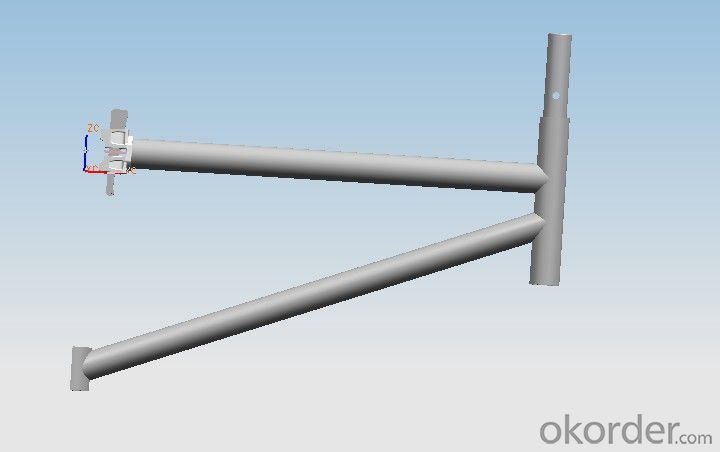

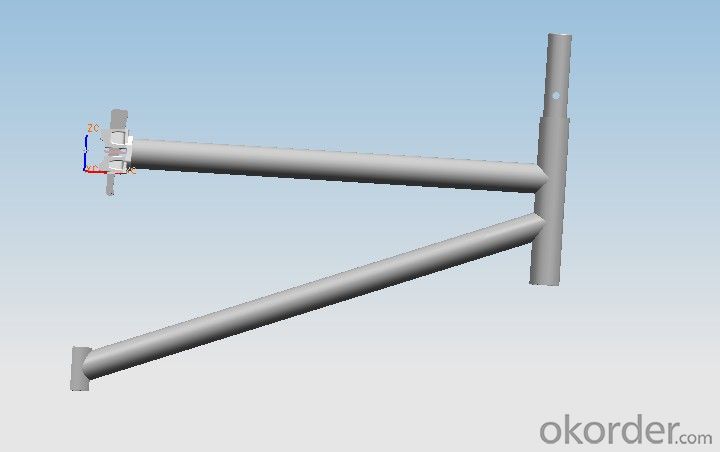

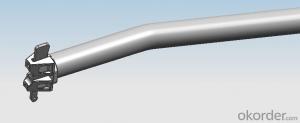

Ringlock System Side Bracket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

48.3 diameter x 3.2 thick high grade steel standard with arosette at 500mm intervals

Up to 8 connectons made at one level

Narrow opening in rosette position the ledgers at right angles

Wide opening in rosette allows alignment of ledgers and diagonal braces at the required angle

Connected by sliding wedge head forming part of the ledger over the rosette and inserting wedge into opening

NGM is a diversified private enterprise specialized in pressed, drop forged, casted and sheet metal items production as well as trading and logistics. The company covers an area of 25,000 m2, possesses standard factory of 6000m2 with fixed assets of 18 million RMB and 150 pieces of specialized equipment and over 200 employees. So far, NGM has been always committing great efforts on internationalization and stability of quality. The company strictly implement ISO9001:2008 international quality system and was continuously awarded as AAA credit enterprises in 2005 and 2006.

We are professional scaffold & couplers manufacturers with years' experience.To guarantee the quality and technology is our development objective.The products as follow:

1. Cuplock System / Ringlock System /Kwikstage, H-frame

2. Screw Jack / U-head jack / Props / Steel Plank

3. Drop forged / Pressed couplers

4. Tower with wheels

We work for the based items(Stamping, fabrication and machining) and get the best price for some other parts from our 200 qualified supplier, these allow us have been providing to our valued customers from overseas(U.S., U.K, Australia, Canada, Germany, France) the following benefits and advantages:

Competitive pricing with good quality.

Turn-key solution to procurement of different types of components.

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- Whether or not the double screw nut is used on the important bolt connection, the degree of the fastening, whether the steel bar is pressed according to the rules, and the steel wires are bundled together

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

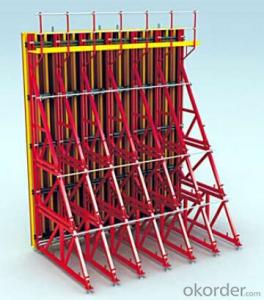

- Climbing frame installation processInstallation of platform --- display base, installation guide, assembling components - horizontal truss beam with the bolt on the guide rail, the main frame vertical rod buckle on the beam - diagonal rod buckle on the vertical rod and beam - wall installation guide device, the frame structure of unloading with elevated body, the erection of scaffolding, the laying of the intermediate layer or temporary scaffolding and temporary building structure frame of pulling and hanging outside the dense mesh safety net - loaded third beams to guide seat -

- Q: The difference between the scaffold and the scaffold

- The climbing frame is the kind of iron that is assembled by a large construction site

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- Floor scaffold:Advantage:1) large bearing capacity. When the scaffolding geometry and structure comply with the relevant requirements, under normal circumstances, the bearing capacity of 15kN ~ 35kN of the single column scaffold (1.5tf ~ 3.5tf, design value).

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- Floor scaffold:Advantage:1) large bearing capacity. When the scaffolding geometry and structure comply with the relevant requirements, under normal circumstances, the bearing capacity of 15kN ~ 35kN of the single column scaffold (1.5tf ~ 3.5tf, design value).Clamp and Tube Scaffold2) easy to install and disassemble, set up flexible. Because the length of the steel tube is easy to adjust and the fastener is convenient to connect, the utility model can be used for various buildings and structures with various planes and elevations.3, compared with the economy, the processing is simple, and the investment cost is low; if the geometric dimensions of the scaffold are carefully designed, and the utilization rate of the steel tube is improved, the material consumption can also obtain better economic effect. Fastener steel pipe frame equivalent to 15 square meters per square meter of construction steel.

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- The climbing frame, which is also called the lifting frame, can be divided into several types, such as hydraulic, electric, manual and so on. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction.

Send your message to us

Ringlock System Side Bracket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords