Ringlock System O-bridging Transom

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

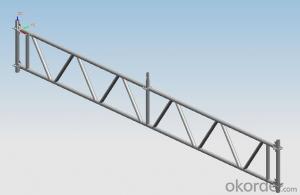

48.3 diameter x 3.2 thick high grade steel standard with arosette at 500mm intervals

Up to 8 connectons made at one level

Narrow opening in rosette position the ledgers at right angles

Wide opening in rosette allows alignment of ledgers and diagonal braces at the required angle

Connected by sliding wedge head forming part of the ledger over the rosette and inserting wedge into opening

Scaffolding system provides total flexibility to lock in any angle plus quickly and accurately aligns at 90 degree angles using the keyhole positions. Each rosette can accommodate up to eight connections at one time. Our system scaffolding can increase your efficiency by decreasing scaffold construction time by two-thirds.

The high-strength Mouthpiece uses a Wedge Pin with a reverse slope. The Wedge Pin engages the Rosette entirely through its vertical surface, ensuring a properly seated Mouthpiece on the Rosette while the Wedge Pin is in place. The lobes are reversed to dramatically increase the compression area at the bottom of the Mouthpiece.

We are professional scaffold & couplers manufacturers with years' experience.To guarantee the quality and technology is our development objective.The products as follow:

1. Cuplock System / Ringlock System /Kwikstage System, H-frame

2. Screw Jack / U-head jack / Props / Steel Plank

3. Drop forged / Pressed couplers

4. Tower with wheels

We work for the based items(Stamping, fabrication and machining) and get the best price for some other parts from our 200 qualified supplier, these allow us have been providing to our valued customers from overseas(U.S., U.K, Australia, Canada, Germany, France) the following benefits and advantages:

· Hot dipped galvanized

· No bolts or screws

· Premeasured components

· Conforms to any angle or curve

· Rigid and safe

· Versatile

· Can be used in conjunction with tube and clamp

· Maintenance free

We continue to manufacture many products in our factory. This provides many local jobs and allows us to make different custom products with a quick turnaround, giving us a competitive edge.

We have been always committing great efforts on internationalization and stability of quality. The company strictly implement ISO9001:2008 international quality system and was continuously awarded as AAA credit enterprises in 2005 and 2006.

Safety is always a factor in manufacturing and selling the many products. We have offered safety training programs for many years. We will continue to do so for the safety of our employees and customers.

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- Regular inspection of the climbing device should check the connections. In particular, the following parts of the site to focus on inspection and reinforcement: according to the design requirements of the bolt with spring washers

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction. It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material. And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings.

- Q: The difference between the scaffold and the scaffold

- The climbing frame is the kind of iron that is assembled by a large construction site

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- 3, compared with the economy, the processing is simple, and the investment cost is low; if the geometric dimensions of the scaffold are carefully designed, and the utilization rate of the steel tube is improved, the material consumption can also obtain better economic effect. Fastener steel pipe frame equivalent to 15 square meters per square meter of construction steel.

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- . It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

Send your message to us

Ringlock System O-bridging Transom

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords