Rich Stock 201 304 430 BA Stainless Steel Sheet/coil/sus

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick information of 304 stainless steel coil

Model Name | 304 stainless steel coil |

Type | 201,202,304,304l,316,316l,321,410,430 |

Color | Silver white |

Standard | ASTM,AISI,DIN |

Surface | No.1,No.4,2B,BA,HL,8K, mirror |

Thickness | 0.3-6.0mm, or as your requirement |

Width | 100mm-2000mm, or as your requirement |

Length | 1000mm-6000mm, or as your requirement |

Feature | Corrosion and heat resistance, good toughness |

Application | 1: Chemical industry equipment, industrial tanks 2: Medical instruments, tableware, kitchen utensil and kitchen ware. 3: Architectural purpose, milk or food processing facilities. 4: Hospital equipment, interior exterior decoration for building 5: Architectural purposes, escalators, kitchen ware and vehicles. Or they can be made as your requirement. |

Chemical composition & physical properties

Chemical composition of Stainless Steel 304 | ||||||||

chemical element | C | Si | Mn | P | S | Cr | Ni | Others |

Ingredient | <=0.07 | <=1.0 | <=2.0 | <=0.035 | <=0.03 | 17.0-19.0 | 8.0-11.0 | |

Physical Properties of Stainless Steel 304 | |

Tensile Strength (MPa) | 520 |

Compression Strength (MPa) | 205-210 |

Proof Stress 0.2% (MPa) | 205-210 |

Elongation A5 (%) | Min40 |

Hardness Rockwell B | 92 |

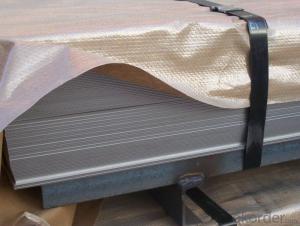

Packaging & Shipping

Packaging Detail

Package | 1.Export sea worthy package + water proof paper + wooden pallet 2.Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professional teams 4.Professional shipping line |

Delivery Time | 7-15 days after deposite |

Our Services

Pre-sale Service

1.Sample can be offered with sample charge and courier fee by buyer's side.

2. We have full stock,and can deliver within short time.Many styles for your choices.

3.OEM and ODM order are accepted, Any kind of logo printing or design are available.

4.Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you

5.All of our products are produce by our professional workman and we have our high-work-effect foreign

trade team, you can totally believe our service.

6.We have 8 year experience of design, manufacture and sell lingerie, we cherish every order from our honor.

After-sale choose

1. We are very glad that customer give us some suggestion for price and products.

2. If any question,please contact with us freely by E-mail or Telephone.

- Q: What is the lifespan of stainless steel strips?

- The lifespan of stainless steel strips can vary depending on various factors such as the quality of the steel, the environment it is exposed to, and how well it is maintained. However, with proper care and maintenance, stainless steel strips can have a lifespan of several decades or even longer.

- Q: What are the different types of slitting for stainless steel strips?

- Stainless steel strips can be slit using various methods, each offering unique advantages and applications. Among the commonly used techniques are: 1. Utilizing circular blades, rotary slitting is a versatile method applicable to different thicknesses of stainless steel. It ensures high-quality and precise cuts, making it ideal for thinner strips. 2. Guillotine slitting involves a straight-line blade resembling a guillotine, making it suitable for thicker strips. This method boasts speed and efficiency, enabling it to handle large material volumes. 3. Crush cutting relies on two rotating circular blades, where one applies pressure to the material while the other cuts through it. This technique excels in producing clean and straight cuts, often used for thinner stainless steel strips. 4. Razor slitting entails the use of a single razor blade to cut the strips. It is commonly employed for thinner gauge materials, delivering very narrow strips with remarkable accuracy and precision. 5. Shear slitting utilizes two blades moving past each other in a scissor-like motion to cut the strips. This method is frequently used for thicker strips and can efficiently handle substantial material volumes. Each slitting method has distinct advantages and suits different applications. The choice depends on factors such as strip thickness, required cutting accuracy, and desired production volume.

- Q: Can stainless steel strips be used in water distribution systems?

- Yes, stainless steel strips can be used in water distribution systems. Stainless steel is highly resistant to corrosion, making it an ideal material for water distribution systems. It is capable of withstanding the harsh conditions of water distribution, including exposure to different pH levels, chemicals, and varying temperatures. Stainless steel strips also have a smooth surface, which minimizes the risk of bacterial growth and contamination in the water supply. Additionally, stainless steel is a durable and long-lasting material, ensuring the longevity and reliability of the water distribution system.

- Q: Can stainless steel strips be used in the production of water treatment equipment?

- Yes, stainless steel strips can be used in the production of water treatment equipment. Stainless steel is a popular choice in the water treatment industry because of its excellent corrosion resistance properties. It is resistant to rust, staining, and corrosion, making it suitable for use in water treatment equipment that is exposed to water or other corrosive substances. Stainless steel strips are often used to manufacture components such as pipes, tubes, valves, fittings, and filter housings that are essential for the effective and efficient treatment of water. Additionally, stainless steel is easy to clean and maintain, ensuring the longevity and reliability of the water treatment equipment.

- Q: What are the mechanical properties of 111 stainless steel strips?

- The mechanical properties of 111 stainless steel strips may differ based on factors like the manufacturing process and specific alloy composition. However, in general, stainless steel strips designated as 111 exhibit several crucial mechanical properties. 1. Tensile Strength: Typically, 111 stainless steel strips possess a high tensile strength, indicating their ability to withstand maximum tensile stress before failure. This quality makes them suitable for applications that require strength and resistance to deformation. 2. Yield Strength: The yield strength of 111 stainless steel strips signifies the stress at which the material permanently deforms. It is a critical property for determining the material's resistance to deformation under load. 3. Hardness: Often, stainless steel strips labeled as 111 have a high level of hardness, which measures their resistance to scratching, indentation, or penetration. This characteristic contributes to their durability and wear resistance. 4. Ductility: Ductility refers to a material's capacity to deform under tensile stress without breaking or fracturing. Although stainless steel generally possesses lower ductility compared to other metals, the specific ductility of 111 stainless steel strips can vary based on factors like alloy composition and processing method. 5. Corrosion Resistance: Stainless steel, including 111 stainless steel strips, is renowned for its exceptional resistance to corrosion. This property arises from the presence of chromium in the alloy, which forms a protective oxide layer that safeguards the material against rust and corrosion in diverse environments. It is important to recognize that these mechanical properties can slightly vary depending on the specific alloy composition, heat treatment, and manufacturing process employed in the production of 111 stainless steel strips. Therefore, referring to the manufacturer's specifications or conducting tests on the material is advisable to obtain precise mechanical property data for a particular application.

- Q: Can stainless steel strips be used in the oil refinery equipment?

- Yes, stainless steel strips can be used in oil refinery equipment. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for use in harsh environments such as oil refineries. It has excellent resistance to corrosion, high temperatures, and chemical exposure, which are important factors in the oil refining process. Stainless steel strips can be used in various components of oil refinery equipment such as heat exchangers, pipes, tanks, and valves, ensuring their longevity and functionality in the refinery operations. Additionally, stainless steel is easy to clean and maintain, making it a preferred choice in the oil refining industry.

- Q: Can 111 stainless steel strips be coated with anti-fingerprint coatings?

- Yes, 111 stainless steel strips can be coated with anti-fingerprint coatings. Anti-fingerprint coatings are designed to reduce the visibility of fingerprints and smudges on stainless steel surfaces, making them easier to clean and maintain. This coating can be applied to various stainless steel grades, including 111 stainless steel. However, it is important to consult with a professional coating supplier or manufacturer to ensure that the specific anti-fingerprint coating is compatible with 111 stainless steel and meets the desired performance requirements.

- Q: Can 111 stainless steel strips be annealed for improved ductility?

- Yes, 111 stainless steel strips can be annealed for improved ductility. Annealing is a heat treatment process that involves heating the material to a specific temperature and then cooling it slowly. This process helps to relieve internal stresses in the material and allows for the rearrangement of atoms, resulting in improved ductility and reduced hardness. By annealing the stainless steel strips, they can become more malleable and easier to work with, making them suitable for various applications where increased ductility is desired.

- Q: Can 111 stainless steel strips be used in the oil and gas industry?

- Indeed, the oil and gas industry can utilize 111 stainless steel strips to great effect. This particular grade of stainless steel, 111 stainless steel, is widely employed due to its commendable resistance against corrosion, remarkable strength, and exceptional malleability. Such attributes render it suitable for a diverse range of applications within the oil and gas sector, encompassing piping, storage tanks, heat exchangers, and various equipment. Moreover, 111 stainless steel strips are capable of withstanding harsh environmental conditions, including exposure to corrosive substances, high temperatures, and pressure, thereby solidifying their status as a dependable choice for the oil and gas industry.

- Q: How are stainless steel strips manufactured?

- Stainless steel strips are manufactured using a combination of processes that involve melting, rolling, and annealing. The first step in the manufacturing process is melting the raw materials, which typically include iron ore, chromium, and nickel, in a furnace at extremely high temperatures. This melting process ensures that the elements are well mixed and form a homogeneous molten metal. Once the molten metal is obtained, it is poured into large molds to form slabs or billets. These slabs are then heated and rolled between a series of rollers to reduce their thickness and form long, flat strips. This rolling process is repeated several times, with each pass reducing the thickness of the steel strip until the desired dimensions are achieved. After the rolling process, the stainless steel strips undergo an annealing treatment. Annealing involves subjecting the strips to high temperatures and controlled cooling to relieve internal stresses, improve ductility, and enhance corrosion resistance. This process also helps to refine the grain structure of the steel, resulting in improved mechanical properties. Once the annealing is complete, the stainless steel strips may undergo additional processes such as pickling, where they are immersed in an acid solution to remove any surface impurities or scale. They may also be cold-rolled to further refine the dimensions and surface finish of the strips. Finally, the stainless steel strips are cut into their desired lengths and widths, and they may be further processed or treated depending on the intended application. These strips can then be used in a wide range of industries, including automotive, construction, manufacturing, and kitchenware, among others. Overall, the manufacturing process of stainless steel strips involves a careful balance of melting, rolling, annealing, and finishing steps to achieve the desired properties and dimensions of the final product.

Send your message to us

Rich Stock 201 304 430 BA Stainless Steel Sheet/coil/sus

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords