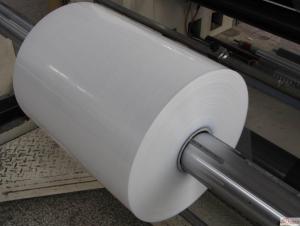

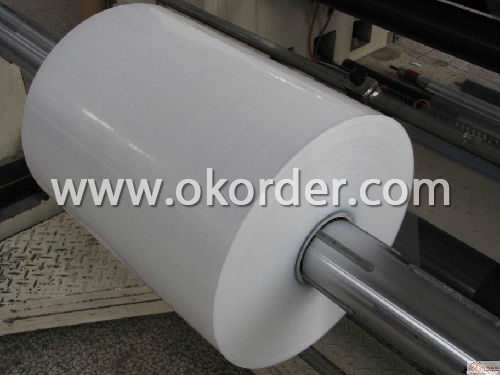

Release Film (HDPE/PET/BOPP)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*20'FCL m²

- Supply Capability:

- 400000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical Data of Release Film:

Material | PE |

Gsm | 15-80 |

Density | 0.941~0.960 |

Colour | White, blue, pink and any common color |

Width | 50-2100MM |

Roll diameter | As per customer request |

Major ingredient | PE and filler |

5% Tensile force at break point g/inch | MD>200,CD>200 |

Tensile force at break point g/inch | MD>800,CD>600 |

Elongation(%) | MD>200,CD>300 |

Heat resistance (%) | Vertical<5 |

Technology | Casting |

Extinction treatment | Treated |

Application of Release Film:

Release film is widely used in waterproofing industry, it has a good feature for waterproof and moisture proof, so it is mainly used as the surface material for waterproof membrane. We can also provide other types of release film that can be used in disposable personal healthcare products and disposable medical protection products.

- Q: What is the impact of TPO waterproofing membrane welding performance?

- 2. The surface cleanliness of the web; 3. Does the welding temperature match the welding speed; 4. Welding method, test welding, manual three-step welding.

- Q: Waterproof electrode, waterproof welding

- 2, start welding should be in the vicinity of the weld without water at the arc. After the arc short arc quickly arc to the weld, with the arc to withstand some of the overflow. In the edge of the weld to form a pool after the arc immediately lead to the steel, the two sides together and gradually welded up. Under normal circumstances should be continuous arc, once the welding stopped, the tip of the electrode will not be able to lead the original arc

- Q: Surfacing isolation layer is the application of what, how to achieve surfacing isolation layer weld.

- The surfacing isolation layer is mainly used to separate the main surfacing layer from the base metal, especially when the surfacing layer is welded directly to the base material. It is usually used with the third component, but with the surfacing layer and Base metal can be a good fusion of metal welding consumables, in the surfacing surface of the first welding a layer, and then on this basis and then need to re-welding the metal.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2008 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | 20.00% North America 10.00% South Asia 10.00% Southern Europe 10.00% Northern Europe 10.00% Central America 10.00% Eastern Europe 5.00% Western Europe 5.00% Eastern Asia 5.00% Oceania 5.00% Africa 5.00% Southeast Asia 5.00% South America |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; Japanese |

| b) Factory Information | |

| Factory Size: | Above 20000 square meters |

| No. of Production Lines | 5-10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Negotiated |

Send your message to us

Release Film (HDPE/PET/BOPP)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*20'FCL m²

- Supply Capability:

- 400000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords