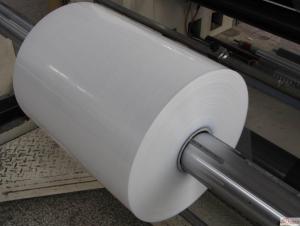

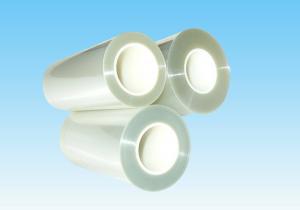

Brown Kraft Silicon Release Paper

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 MT m²

- Supply Capability:

- 400000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.) Silicon Release Paper is used for self adhesive paper converting application and packing purpose

2.) Substance: 60-120gsm

3.) Reel width: in reels OEM

4.) Laminate: PE, PET, OPP coated

5.) Silicon coating: single side or double sides

6.) Base paper colour: white, light yellow or unbleached brown ect.

7.) Quality: light release force, normal release force and heavy release force

Silicon Release Paper technical data:

PARAMETERS | UNIT | VALUE |

Substance | gsm | 60-180 |

Laminated material | PE/PET/OPP | |

Base paper | wf paper/kraft paper | |

Colour | white/yellow/brown | |

Release force | g/25mm | ≥140 |

Moisture | % | 7 |

Tensile strength MD | N/cm | ≥30 |

Tensile strength CD | N/cm | ≥15 |

Heat resistance | °C | ≥120 |

Max width | mm | 1700 |

Silicon Release Paper pictures:

- Q: What is the impact of TPO waterproofing membrane welding performance?

- 2. The surface cleanliness of the web; 3. Does the welding temperature match the welding speed; 4. Welding method, test welding, manual three-step welding.

- Q: Waterproof electrode, waterproof welding

- 3, the more the more welding when the weld, the better the location, until the leak attributed to a little. At this time according to the size of the overflow pressure can be used in different ways: 1, with a tap into the cone of the welding plug, such as holes, temporarily blocked the hole, and then welding. 2, if the hole small, but the water more urgent. At this time may wish to elongate the arc, the use of electric home hot hole around the baked, the use of peripheral metal heat expansion, temporary swelling of the pores or simply hammer the hole immediately after the welding. Require this spot welding to be quick and accurate. When the droplets will be blocked after the hole, immediately off the arc. Action to be fast, so that the droplets have been blocked quickly cooled and completed welding. If the arc is too slow, then the back of the droplets have been re-melting, re-blowing under pressure. To be a little at the hole after the cooling, according to the need for re-welding.

- Q: Surfacing isolation layer is the application of what, how to achieve surfacing isolation layer weld.

- Surfacing as a material surface modification of an economical and rapid process, more and more widely used in various industrial sector parts manufacturing repair.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2008 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | 20.00% North America 10.00% South Asia 10.00% Southern Europe 10.00% Northern Europe 10.00% Central America 10.00% Eastern Europe 5.00% Western Europe 5.00% Eastern Asia 5.00% Oceania 5.00% Africa 5.00% Southeast Asia 5.00% South America |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; Japanese |

| b) Factory Information | |

| Factory Size: | Above 20000 square meters |

| No. of Production Lines | 5-10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Negotiated |

Send your message to us

Brown Kraft Silicon Release Paper

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 MT m²

- Supply Capability:

- 400000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords