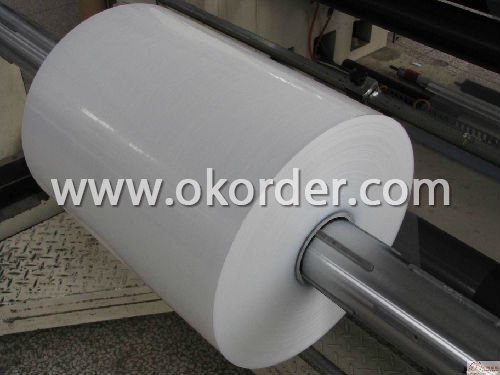

High Quality HDPE/PET/BOPP Release Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*20'FCL m²

- Supply Capability:

- 400000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical Data of Release Film:

Average (mic) | 17.81 | Max / Min | 18.5/17.2 | |

Tolerance (%) | 0.06 | |||

Tensile Strength (Mpa) | MD/TD | 150/343 | ||

Elongation of Break (%) | MD/TD | 149/51 | ||

Elastic Modulus (Mpa) | MD/TD | 2237/4366 | ||

Thermal Shrinkage (%) | MD/TD | 3.5/2.5 | ||

Friction Coefficient | Back | Static | 0.43 | |

Dynamic | 0.44 | |||

Front | Static | 0.44 | ||

Dynamic | 0.44 | |||

Surface Tension (mN/m) | 38 | |||

Haze (%) | 1.09 | |||

Gloss (%) | 93.5 |

Release Film Applications:

1) Books and magazines, pictures, promotional materials; non-drying adhesive, paper bag, clothes lag, liquor, food, cosmetic, medicine

wrapping box

2) Blueprint document, outdoor advertisement, spray paintings, post, digital print

3) Wedding photograph, photo album

4) The width is from 330mm to 1800mm

Package:

Paper tube: 10cm, Carton measure:45*45*(product width+1.5)cm ,15tons/20GP with carton packing

- Q: What is the impact of TPO waterproofing membrane welding performance?

- Factors affecting the welding performance of TPO coil mainly in the following areas: 1. Material melting point and welding window;

- Q: Waterproof electrode, waterproof welding

- 2, start welding should be in the vicinity of the weld without water at the arc. After the arc short arc quickly arc to the weld, with the arc to withstand some of the overflow. In the edge of the weld to form a pool after the arc immediately lead to the steel, the two sides together and gradually welded up. Under normal circumstances should be continuous arc, once the welding stopped, the tip of the electrode will not be able to lead the original arc

- Q: Surfacing isolation layer is the application of what, how to achieve surfacing isolation layer weld.

- The surfacing isolation layer is mainly used to separate the main surfacing layer from the base metal, especially when the surfacing layer is welded directly to the base material. It is usually used with the third component, but with the surfacing layer and Base metal can be a good fusion of metal welding consumables, in the surfacing surface of the first welding a layer, and then on this basis and then need to re-welding the metal.

Send your message to us

High Quality HDPE/PET/BOPP Release Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*20'FCL m²

- Supply Capability:

- 400000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords