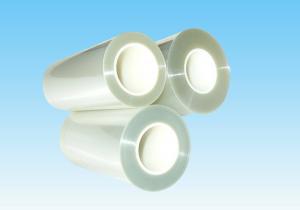

PET Release Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*20'FCL m²

- Supply Capability:

- 400000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.PET film has good printability,

2.excellent dimensional stability,

3. good surface barrier properties

PET film is used in a wide range of applications, due to its excellent combination of optical, physical, mechanical, thermal, and chemical properties, as well as its unique versatility.

Technical Data of Release film:

Material | PE |

Gsm | 15-80 |

Density | 0.941~0.960 |

Colour | White, blue, pink and any common color |

Width | 50-2100MM |

Roll diameter | As per customer request |

Major ingredient | PE and filler |

5% Tensile force at break point g/inch | MD>200,CD>200 |

Tensile force at break point g/inch | MD>800,CD>600 |

Elongation(%) | MD>200,CD>300 |

Heat resistance (%) | Vertical<5 |

Technology | Casting |

Extinction treatment | Treated |

Application of Release film:

1.Self-adhesive waterproof membranes

2.Foam Tape

3.Anti-corrosion Tape

4.Bituminous

5.Asphalt

6.Petro pipe tape

7.Self-adhesive waterproof membranes

Package of Release film:

Paper tube: 10cm, Carton measure:45*45*(product width+1.5)cm

15tons/20GP with carton packing

- Q: What is the impact of TPO waterproofing membrane welding performance?

- Dow Chemical TPO and Basel TPO due to the different grades of production technology, raw material ratio is different from the formula system for the performance of the material melting point, polymerization, molecular weight distribution index, melt index, melt strength, weldability are not same. It is recommended that attention be given to the above factors in the course of the test

- Q: Waterproof electrode, waterproof welding

- 2, start welding should be in the vicinity of the weld without water at the arc. After the arc short arc quickly arc to the weld, with the arc to withstand some of the overflow. In the edge of the weld to form a pool after the arc immediately lead to the steel, the two sides together and gradually welded up. Under normal circumstances should be continuous arc, once the welding stopped, the tip of the electrode will not be able to lead the original arc

- Q: Surfacing isolation layer is the application of what, how to achieve surfacing isolation layer weld.

- Surfacing as a material surface modification of an economical and rapid process, more and more widely used in various industrial sector parts manufacturing repair.

Send your message to us

PET Release Film

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*20'FCL m²

- Supply Capability:

- 400000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords