Silicone Coated PET Release Paper For Waterproofing Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 MT m²

- Supply Capability:

- 400000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicone release kraft paper technical data:

Material: | Kraft paper |

Specification: | 1040mmx3000m |

Thickness: | 78g,83g |

Silicone: | single side /double side |

Usage | Packing,adhesive tape produce and waterproof field |

Silicone release kraft paper details:

Silicone release kraft paper is a silicone coated paper for anti-sticky purpose,which is applied in adhesive packaging industry.

Structure : silicone oil + raw paper + silicone oil

Weight: 50gsm ~ 160gsm

Width: 50mm ~ 1300mm

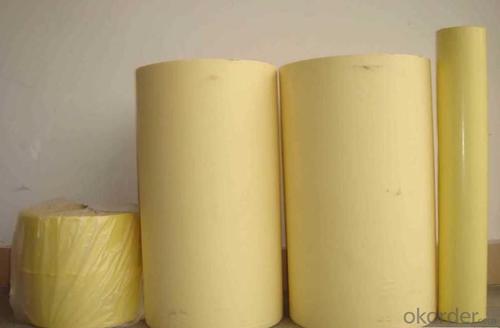

Packaging: jumbo rolls with woven cloth packing

Shippment: containers by lorry, train or ship

Peel-off strength: as required

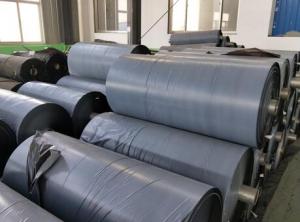

Silicone release kraft paper pictures:

- Q: What is the impact of TPO waterproofing membrane welding performance?

- 2. The surface cleanliness of the web; 3. Does the welding temperature match the welding speed; 4. Welding method, test welding, manual three-step welding.

- Q: Waterproof electrode, waterproof welding

- Example: Water supply with steel pipe Company Caoxi - central pumping station Huang She Lou 800 mm steel pipe leakage. The excavation, inspection found: weld welding position of about 600 - 700 mm cracking, the bottom of the crack width of nearly 15 mm. Pipe sewage for a reason can not be drained, the water depth of about 200 mm, the sewage at a long flow. As the top of the water welding is different from the underwater wet welding, even with the T202 underwater electrode, the front overflow will break through the arc bubble, and the welding can not be carried out.For the commonly used electrode, the water will quickly cool the electrode coating, Condensation, no longer arc. ?In order to offset the water pressure from the leak and compensate for the heat loss of the welding water cooling, the use of small diameter electrode (2.5-3.2 mm) welding current 1.5-2 times larger than usual, short arc welding. From the direction of welding to be accurate, action to be fast, arc is not easy to use scratch method, easy to use touch method. Special attention, must not be convenient at the location of welding. In this case, when the weld is gradually reduced and concentrated in the lowest part of the welding position, the water is more urgent, welding will be more difficult (in general, the pipeline should be welded from the welding position. 1, the 12 mm of steel into the crack, the outer surface and the steel than the wall flat. , At the bottom of the pipe will be reinforced and pipe wall spot welding, then the steel into the crack by paragraph, every 50 mm on both sides of the spot welding. When the crack is too small can not break into the steel, for smaller steel bars, until the basic fill the cracks, control the gap to be welded less than 3 mm. Then the amount of water is clearly reduced, can be formally welded (it is necessary to wet gloves, clothes for dry, to prevent electric shock)

- Q: Surfacing isolation layer is the application of what, how to achieve surfacing isolation layer weld.

- The surfacing isolation layer is mainly used to separate the main surfacing layer from the base metal, especially when the surfacing layer is welded directly to the base material. It is usually used with the third component, but with the surfacing layer and Base metal can be a good fusion of metal welding consumables, in the surfacing surface of the first welding a layer, and then on this basis and then need to re-welding the metal.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2008 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | 20.00% North America 10.00% South Asia 10.00% Southern Europe 10.00% Northern Europe 10.00% Central America 10.00% Eastern Europe 5.00% Western Europe 5.00% Eastern Asia 5.00% Oceania 5.00% Africa 5.00% Southeast Asia 5.00% South America |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; Japanese |

| b) Factory Information | |

| Factory Size: | Above 20000 square meters |

| No. of Production Lines | 5-10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Negotiated |

Send your message to us

Silicone Coated PET Release Paper For Waterproofing Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 MT m²

- Supply Capability:

- 400000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords