reinforcing bar steel rebars in bundles construction building material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 11 m.t.

- Supply Capability:

- 111111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

reinforcing bar steel rebars in bundles construction building material

1.Diameter:6mm-50mm

2.Length:6-12m,coils,U shape

reinforcing bar steel rebars in bundles construction building material

We have large stock for BS4449 460B,500B, HRB400 (12MM,16MM,20MM)

1. BRIEF INTRODUCTION

Rebar is common known as steel reinforcing bar, usually applied to reinforced concrete and reinforced masonry structures. Formed from mild steel, it is given ribs for better frictional adhesion to the concrete. In other words rebar is an iron rod, a weldable plain reinforcing steel bar, that it can be also used for steel meshes.

Type | Reinforced Steel Rebar |

Standard Grade | GB(HRB335/HRB400/HRB500) |

BS4449-1997 GRADE 250B,460B, BS4449-2005 GRADE 500B | |

ASTM A615 GRADE 40,60,75, ASTM A706 | |

DIN488-1 420S/500S,BST500S | |

JIS G3112 SD35, SD40, SD50 | |

NFA 35016 FE E 400, FE E 500 | |

CAN/CSA.G30.18-M92 GR400,GR400W GR500 | |

IS739 S 400, S 400W | |

NCH204 A63-42H,A44-28H | |

UNE 36-068-94 B500S | |

AS4671 GRADE 500N | |

GOST A3 R A500C | |

Diameter | 6mm-50mm etc. |

Surface finished | Deformed |

Epoxy coating | |

Galvanized coating | |

Length | 6m, 9m,12m ,15m U shape or as your request |

Application | construction industry with all types of reinforced concrete structures and so on |

Packing | standard export packing, or as per customers' requirement |

Quality | First quality |

Production capacity | 1000 tons for one day |

Annual outcome | 600,000MT |

Package | by bundles,2-3tons each bundle |

provider | sample , mill test report, any time can visit my factory |

Delivery time | A.S.A.P |

Others | 1. all the production process are made under the ISO 9001 strictly |

2. our products conform to all the standards | |

3. we can offer special specification products as per our customers | |

4. we can offer the original mill test certificate and original production |

- Q: Are steel buildings more durable than concrete building?

- Not necessarily as most concrete buildings are steel re-inforced anyway. As for durable, if talking time based, no, because steel will corrode and concrete will not. The good thing about concrete is that it has good load bearing capability over wide spans whereas steel will bend unless properly supported. Concrete is cheaper also....

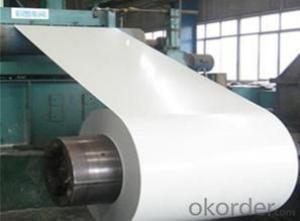

- Q: What are the different types of steel coil treatments?

- There are several types of steel coil treatments, including pickling, oiling, and galvanizing. Pickling involves immersing the steel coil in an acid bath to remove impurities and scale, resulting in a clean surface. Oiling is the process of applying a thin film of oil to the coil to prevent corrosion during storage and transportation. Galvanizing is a treatment where a layer of zinc is applied to the steel coil, providing excellent protection against corrosion.

- Q: How can I arbitrate quality of steel before purchasing it??

- The quality of the alloy can be very well be judged by its appearance and lustrous surface. The more luster on the surface the more refine will the steel be. To judge its tenacity and endurance, the alloy can be subjected to a series of procedures involving stress and shock. The reaction to these processes can determine whether the steel be fit for the purpose required.

- Q: Can steel coils be coated with holographic patterns?

- Yes, steel coils can be coated with holographic patterns. This process involves the application of a holographic film or coating onto the surface of the steel coils, creating a visually appealing and unique holographic effect. This coating can be used for various purposes such as branding, security, or aesthetics in industries like automotive, packaging, or electronics.

- Q: How do steel coils compare to other materials like aluminum or copper?

- When comparing steel coils to other materials like aluminum or copper, it is evident that they possess both advantages and disadvantages. One primary advantage of steel coils lies in their remarkable strength and durability. Steel is renowned for its high tensile strength, enabling it to withstand heavy loads and high stress without any deformation. As a result, steel coils are highly suitable for various applications that demand robust and resilient materials, including construction, automotive manufacturing, and transportation industries. In contrast, aluminum and copper are generally softer and less strong than steel, rendering them less appropriate for heavy-duty tasks. Another advantage of steel coils is their cost-effectiveness. In comparison to aluminum or copper, steel is a relatively inexpensive material, making it a more accessible option for large-scale projects or mass production. Furthermore, steel is highly recyclable, contributing to its cost-effectiveness and sustainability. Nonetheless, steel coils do have some disadvantages when compared to aluminum or copper. One notable drawback is their weight. Steel is significantly denser than aluminum or copper, resulting in heavier steel coils that can be more challenging to handle and transport. This disadvantage can prove to be critical in industries where weight plays a vital role, such as aerospace or electrical applications. Additionally, steel coils are susceptible to corrosion, which is another disadvantage. While aluminum and copper possess natural corrosion resistance, steel is prone to rust and oxidation. Consequently, steel coils require proper protection and coating to prevent corrosion, which adds to the overall cost and maintenance requirements. In conclusion, steel coils offer exceptional strength, durability, and cost-effectiveness when compared to aluminum or copper. However, they are generally heavier and more prone to corrosion. Ultimately, the selection between steel, aluminum, or copper will depend on the specific application, budget, and project requirements.

- Q: What is the minimum diameter of a steel coil?

- The minimum diameter of a steel coil can vary depending on the specific requirements and manufacturing processes, but it is typically around 4 inches or 100 millimeters.

- Q: I have lung cancer. My doctor told me to invest in stainless steel pots to cook with, instead of magnalite. What's the difference between the all stainless steel pots and the Hard-Anodized pots? and are there any stainless steel pots that are nonstick?

- If you are changing cook ware to improve your health, don't go with non-stick, because you will eventually be ingesting all that coating. The best cookware is cast iron, and the next best is stainless steel. The idea behind this recommendation is to reduce as many stresses on your immune system, so your systems can help you heal. There may be lots of other things you can do to eliminate chemicals and toxins from your house and food, so start with one thing at a time. Get some stainless steel mixing bowls, one stainless steel pot to boil water in, and then look into eating more raw foods. Use your blender and broiler. Good luck. I believe you can heal following eliminating the toxins from your house and food.

- Q: My uncle got me some new 'Nam style jungle boots at the px at Fort Worth JSB, and he told me that back in Vietnam, they used to issue guys steel sole boots, that had a sole reinforced with a steel plate, as punji stick d-fence. Is this true, it sounds logical, but I can't figure out how a steel plate in the sole would work. My uncle is kind of a BS'er, plus he wasn't even in Vietnam, much less the Infantry, much less combat, but he was in USAF at the time.

- The steel plate in the boot was about 5 cm long and 2 cm wide, it was located in the midsection of the boot sole but did not cover the heel. Prolonged wear, the humidity and soakings eventually caused the steel piece to break out of the mounding in the inside of the boot and cause blisters.

- Q: How are steel coils used in the production of fireproof doors?

- Steel coils are used in the production of fireproof doors as they are the primary material for constructing the door's core. The steel coils are shaped and layered to create a strong and heat-resistant core, which provides the necessary structural integrity and fire resistance required for fireproof doors.

- Q: How are steel coils used in the manufacturing of suspension systems?

- Steel coils are used in the manufacturing of suspension systems as they provide the necessary support and flexibility to absorb shocks and vibrations, ensuring a smooth and comfortable ride. These coils are typically used in coil spring suspension systems, where they are compressed and stretched to absorb and distribute the weight of the vehicle, maintaining stability and enhancing overall performance.

Send your message to us

reinforcing bar steel rebars in bundles construction building material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 11 m.t.

- Supply Capability:

- 111111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords