Refractory White Brick Fire Brick Fused Azs Brickinsulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

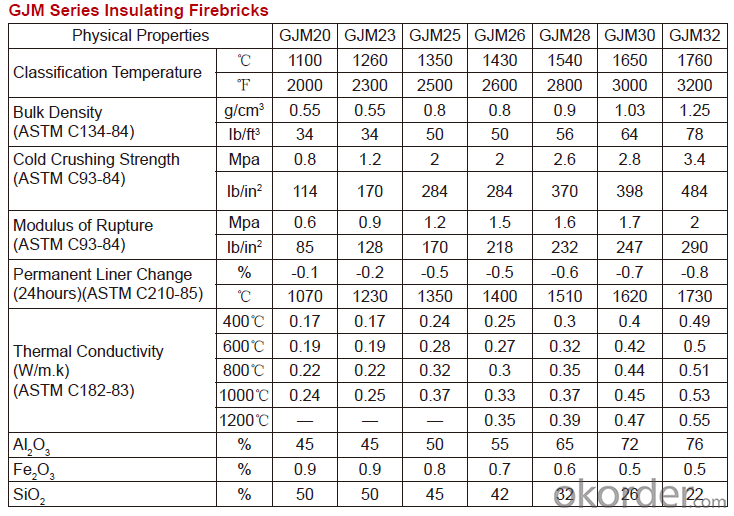

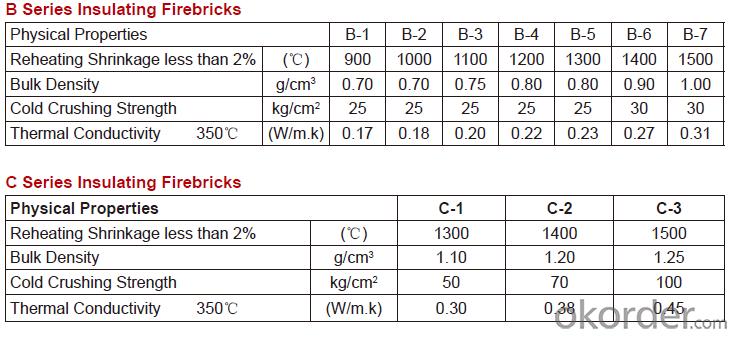

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used for insulation in power boiler walls?

- Certainly! The application of insulating fire bricks for insulation in power boiler walls is possible. These bricks are specifically engineered to possess a low thermal conductivity, thereby enabling them to efficiently insulate power boilers operating at high temperatures. Constructed from lightweight materials like clay and other refractory substances, these bricks exhibit exceptional insulation characteristics while enduring the extreme heat encountered in power boilers. By integrating insulating fire bricks into power boiler walls, heat loss can be minimized, energy efficiency can be enhanced, and the boiler can sustain optimal operating temperatures.

- Q: Can insulating fire bricks be used in the construction of pottery extruders?

- Yes, insulating fire bricks can be used in the construction of pottery extruders. These bricks are known for their high heat resistance, low thermal conductivity, and excellent insulating properties, making them suitable for applications where high temperatures are involved, such as pottery extrusion. They can help maintain a consistent temperature within the extruder, ensuring optimal working conditions for the clay and improving overall efficiency.

- Q: Do insulating fire bricks require special handling?

- Yes, insulating fire bricks do require special handling. These bricks are made from lightweight refractory materials and are designed to withstand high temperatures. Due to their fragile nature, they should be handled with care to prevent breakage or damage. It is recommended to use proper lifting and carrying techniques, such as wearing gloves and using tongs or lifters, to avoid accidents or injuries. Additionally, insulating fire bricks should be stored in a dry and protected area to prevent moisture absorption, which can affect their thermal properties.

- Q: Several kinds of energy-saving bricks

- It can be said that the type of brick is the kind of energy-saving brick. Coal gangue sintered brick (known as red brick), porous brick, hollow brick, aerated concrete block brick, etc..

- Q: How do insulating fire bricks affect overall heating and cooling costs?

- The utilization of insulating fire bricks can have a significant impact on the overall costs associated with heating and cooling. These bricks are specially designed to possess a low thermal conductivity, which makes them highly effective at preventing the transfer of heat. Incorporating insulating fire bricks into the construction of a building greatly reduces the amount of heat lost during colder months, resulting in a decreased need for energy to maintain a comfortable indoor temperature and consequently lowering heating costs. Likewise, during warmer months, insulating fire bricks aid in keeping heat out and maintaining a cooler indoor environment. This diminishes reliance on air conditioning systems, leading to reduced cooling costs. The high thermal resistance of these bricks plays a crucial role in minimizing heat gain from the external environment, offering a more energy-efficient solution. Furthermore, the use of insulating fire bricks can also contribute to the long-term durability and efficiency of heating and cooling systems. By lessening the workload on these systems, they can operate more efficiently, resulting in less wear and tear and potentially extending their lifespan. This can lead to additional cost savings by eliminating the need for frequent repairs or replacements. Overall, insulating fire bricks offer substantial benefits in terms of reducing heating and cooling costs. By enhancing thermal insulation, they facilitate the creation of a more energy-efficient building, ultimately resulting in lower utility bills and a reduced carbon footprint.

- Q: Can insulating fire bricks be used in the construction of smelting furnaces?

- Yes, insulating fire bricks can be used in the construction of smelting furnaces. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for smelting furnaces where heat retention is crucial. They help to minimize heat loss and maintain the desired temperature within the furnace, thus improving energy efficiency and overall performance.

- Q: Can insulating fire bricks be used as a thermal barrier?

- Indeed, insulating fire bricks have the potential to function as a thermal barrier. Specifically engineered with low thermal conductivity, these bricks are adept at reducing heat transfer. Consequently, they are an optimal selection for thermal insulation purposes. Their widespread usage is observed in industries that entail elevated temperatures, including furnaces, kilns, and other heat-intensive procedures. By employing insulating fire bricks, heat loss can be minimized, steady temperatures can be maintained, and energy efficiency can be enhanced. Furthermore, their lightweight composition facilitates effortless handling and installation, thereby augmenting their suitability as a thermal barrier.

- Q: Do insulating fire bricks affect the overall aesthetics of a structure?

- The overall aesthetics of a structure are typically not significantly affected by insulating fire bricks. These bricks are mainly used for their thermal and insulating properties, making them a popular choice for fireplaces, kilns, and furnaces. Insulating fire bricks are commonly made from lightweight materials like clay, alumina, and silica, which can be easily shaped into different sizes and forms. While they may not possess the same visual appeal as traditional bricks or decorative materials, they are often hidden behind a layer of refractory mortar or a decorative facing material. If exposed, the appearance of insulating fire bricks is generally neutral and does not diminish the overall aesthetic appeal of the structure. However, it is worth noting that there are various options in the market for insulating fire bricks, offering different colors and textures. Architects and designers can select from these options to achieve the desired look and feel for the structure. Ultimately, the main focus of insulating fire bricks is their functionality rather than their visual impact. They offer exceptional insulation, resistance to high temperatures, and energy efficiency, making them a practical choice for structures that require heat containment and thermal protection.

- Q: Are insulating fire bricks resistant to electrical conductivity?

- Yes, insulating fire bricks are resistant to electrical conductivity.

- Q: Can insulating fire bricks be used in glass melting furnaces?

- Yes, insulating fire bricks can be used in glass melting furnaces. Insulating fire bricks are made with materials that have high insulating properties, such as lightweight refractory fibers, and are designed to minimize heat loss. In glass melting furnaces, where high temperatures are required, insulating fire bricks can be used to line the walls and roof of the furnace to reduce heat transfer to the surroundings and improve energy efficiency. They can help maintain high temperatures inside the furnace, reduce fuel consumption, and enhance the overall performance of the glass melting process. However, it is important to note that insulating fire bricks may have a lower resistance to chemical attack and wear compared to other refractory materials, so they may need to be supplemented with other types of refractories in certain parts of the furnace where harsh conditions are present.

Send your message to us

Refractory White Brick Fire Brick Fused Azs Brickinsulating Fire Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords