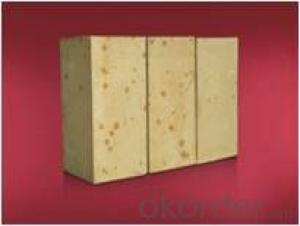

Alumina Silica Refractory Silica Brick for Carbon Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

Our silica brick for carbon furnace has high purity, high density, excellent thermal conductivity, good volume stability, strong ability of resistance to acidic etching, pure in color, precise size and other characteristics, which receives high opinions of customers after the application in a number of carbon enterprises at home and abroad. Therefore, CUNSE silica brick for carbon furnace is gradually becoming the preferred brand of silica brick for carbon enterprises at home and abroad. The excellent performance silica brick has the following characteristics. The low creep, high refractories under load and low residual quartz contents, silicon bricks for hot stove of our company has been successfully applied to various types of hot stoves of major steel companies at home and abroad and the quality has been recognized by the clients.

Feature

Superior resistance to acids (including oxidizing)

Resistance to chlorine

Resistance to thermal shock and pressure changes

Low thermal and chemical expansion

Technical Data

| Brand Item | GZ-95 | RG-95 | JG-94 | ||

| Dome & Wall brick | Checker | Sole & wall brick | Others | ||

| Refractoriness º C ≥ | 1710 | ||||

| Permanent liner change 1450 º C × 2h % | +0.2 0 | ||||

| Apparent Porosity (%) ≤ | 22 | 22 | 23 | 22 | 24 |

| True Density (g/cm3) ≤ | 2.37 | 2.35 | 2.35 | 2.34 | 2.35 |

| Cold Crush Strength (MPa) ≥ | 29.4 | 35 | 30 | 30 | 25 |

| Thermal Expansion(1000 º C ) % | 1.26 | 1.26 | 1.28 | 1.30 | |

| Refractoriness under Load 0.2MPa Ta( º C ) ≥ | 1650 | 1650 | 1650 | ||

| Chemical analysis SiO 2 % ≥ | 95 | 95 | 95 | 94 | 94 |

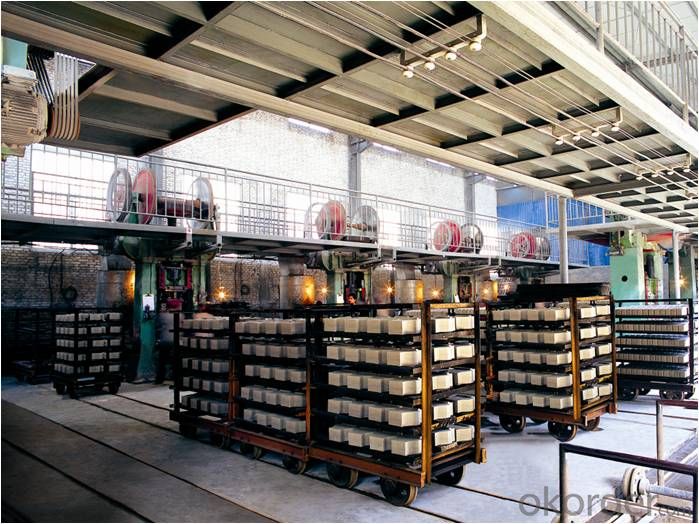

Photos for Workshops

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q: Why will expand when heated brick

- After high temperature after the formation of tridymite and cristobalite and quartz and a small amount of residual glass phase, quartz heating to 220-240 DEG C, in a certain degree of thermal expansion, brick maximum expansion occurs in 100~300 DEG C, 300 expansion before the total amount of expansion is about 70%~75%.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: What is acid refractory?

- Refractory materials are mainly quartz glass products, combined with fused quartz products, silica brick and unshaped refractories. Semi siliceous refractory materials are generally attributed to this category. As for fireclay refractories, they are also classified as semi acidic or weakly acidic refractories. Also, zircon refractory and silicon carbide refractory for special acidic refractory materials are also classified into this category.

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The high thermal conductivity of silica brick all inherits the advantages of traditional coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance.

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- This is a kind of refractory material is divided into three types: semisilica brick (A12O315 ~ 30%), clay brick (A12O330 ~ 48%), high aluminum brick (A12O3>48%).

- Q: The brick is mainly used in the place?

- Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

- Q: Brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass. Tridymite and cristobalite and quartz remaining at low temperature due to phase change, volume changes greatly, so the brick thermal stability at low temperature is very poor. In use, under 800 degrees Celsius, slowly heating and cooling, so as not to produce cracks. The use of temperature in blast furnace so should not be below 800 DEG on.

- Q: Such purpose and scope please give me detailed points thank you

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

Send your message to us

Alumina Silica Refractory Silica Brick for Carbon Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches