Calcium Silicate Bricks Price for High Duty Silica Ceramic Kiln

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 pallet

- Supply Capability:

- 30000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

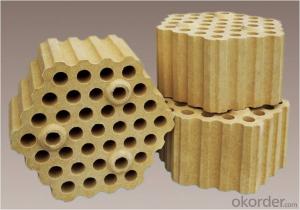

Ceramic firing kiln refractory Silica Brick Description:

Refractory Silica Brick is mainly made of top class silica, via shaping and burning under the high temperature,

Possesses high temperature resistant, high strength and low impurities, etc.

It is mainly used for blast furnaces and hot blast stove.

Features

Ceramic firing kiln refractory Silica Brick Advantage:

1) Silicon oxide is above 95%.

2) Good acid erosion resistance.

3) High softening point

Applications:

Light weight silica bricks are primarily used for furnaces and kilns in metallurgy, steel, power, chemical industry, and electric power and machine building etc areas

Ceramic firing kiln refractory Silica Brick specifications:

Product | AZM-1550 | AZM-1650 | AZM-1680 | |

Index | Index | Index | Index | |

chemical composition | SiC+SiO2 | ≥35 | ≥30 | ≥32 |

Al2O3 | ≥60 | ≥65 | ≥65 | |

Bulk Density(g/cm3) | ≥2.55 | ≥2.65 | ≥2.70 | |

Apparent Porosity (%) | ≤20 | ≤19 | ≤19 | |

Cold Crushing Strength(Mpa) | ≥80 | ≥90 | ≥100 | |

Refractoriness Under Load | ≥1550 | ≥1650 | ≥1680 | |

Thermal Shock Resistance | ≥10 | ≥15 | ≥20 | |

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- Different insulation methods can be adopted according to the length of the stop time and the location and equipment of the overhaul. Gold, refractory material factory specializing in the production of various specifications of brick

- Q: Why will expand when heated brick

- Because the production of raw materials are silica brick, brick with SiO2 content of not less than 95% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- The main damage of silicon carbide side wall brick is stress damage, not chemical erosion. Chemical damage is formed prior to the formation of the groove, and the damage to the chemical erosion is little after the formation of the groove.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Brick bearing soft temperature and close to the melting point, high temperature strength, can be in high temperature (above 1400 degrees) under the condition of long-term use,

- Q: How much is the highest melting point of silicon?

- . True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. The total volume of heating to 1450 DEG about 1.5~2.2% expansion, the residual expansion will make cutting seam sealing, ensure masonry tightness and good structure strength, so that the brick load softening temperature will reach 1750 degrees Celsius above 1620 degrees in the case of the highest melting point.

- Q: Which material is good for furnace refractory?

- Kiln types of refractories is very extensive, selection of refractory materials according to the type of furnace furnace temperature and use of selected refractory material, refractory material is divided into custom products of refractory bricks and unshaped refractory castable series products. According to chemistry, it is divided into acidic, neutral and alkaline materials.

- Q: The brick is mainly used in the place?

- Partitions used in coking and combustion chambers for coke ovens

- Q: Can not use it two brick

- The softening temperature is up to 1640~1670 DEG C, and the volume is stable at high temperature for a long time.

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- That is because the brick load softening point the maximum temperature is 1450 degrees.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Brick bearing soft temperature and close to the melting point, high temperature strength, can be in high temperature (above 1400 degrees) under the condition of long-term use, but the anti alkali erosion ability, thermal shock stability is the worst, a scrap. The brick is generally used in the coke oven, glass kiln. Other industries basically do not use.

Send your message to us

Calcium Silicate Bricks Price for High Duty Silica Ceramic Kiln

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 pallet

- Supply Capability:

- 30000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords