Silica Silicate Mullite Bricks for Hot Blast Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

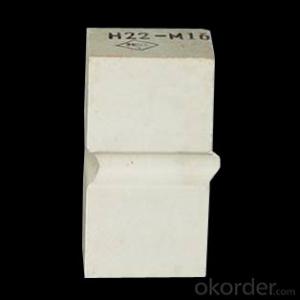

Silicate Mullite Bricks for Hot Blast Furnace

Brief discription for Silicate Mullite Bricks

CMAX Silicate Mullite Bricks are classified according to alumina content ranging from 48% to 90%.

CMAX Silicate Mullite Bricks are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln,regenerator, etc.

Brief features for Silicate Mullite Bricks for Hot Blast Furnace

◆Low thermal conductivity

◆Excellent acid and base slagging resistance

◆High refractoriness

◆Excellent thermal shock resistance

◆Excellent mechanical strength

◆Good spalling resistance and wear resistance.

◆Good corrosion resistance.

◆High-temperature creep rate is quite low.

◆Good volume stability at high temperature.

◆Low bulk density, low thermal conductivity, good thermal insulation performance.

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q: Why will expand when heated brick

- After high temperature after the formation of tridymite and cristobalite and quartz and a small amount of residual glass phase, quartz heating to 220-240 DEG C, in a certain degree of thermal expansion, brick maximum expansion occurs in 100~300 DEG C, 300 expansion before the total amount of expansion is about 70%~75%.

- Q: The specific content is what gb/t2608-2012 brick

- The provisions of the brick classification, technical requirements, test methods,

- Q: The introduction of silica brick

- Brick refers to the content of more than 93% products SiO2. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system. The higher the content of SiO2 in silica raw material, the higher the refractoriness of the product. According to the use of brick varieties, divided into: coke oven silica brick, brick for hot blast stove, electric stove with brick, brick for glass furnaces. According to the transformation is divided into: standard bricks, tiles, bricks and general special brick etc..

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick with silicon oxide content, low melt index, mainly used for glass kiln crown, parapet, wall hanging, small furnace arch superstructure and regenerator.

- Q: What are the main constituents of refractory bricks?

- Refractory brick composition is mainly composed of a variety of aggregate or aggregate and one or more kinds of sticky agent composed of mixed powder particles, when used, must be mixed with one or more liquids, mixing evenly, with strong liquidity. Different refractory bricks are different, such as silicon, aluminum, clay and so on:

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: High temperature refractory material?

- Special materials often use AZS brick (i.e. corundum brick), corundum brick, magnesia chrome bricks, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Insulation refractories are often used diatomite products, asbestos products, insulation board. Unshaped refractories are often used refractory castable, refractory clay, refractory ramming material, refractory plastic and fettling material, fire resistance, gunning, refractory cast material, fireproof coating, lightweight refractory castable, gun mud.

- Q: Such purpose and scope please give me detailed points thank you

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

Send your message to us

Silica Silicate Mullite Bricks for Hot Blast Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords