Insulating Fire Brick - Refractory Mullite GJM32

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

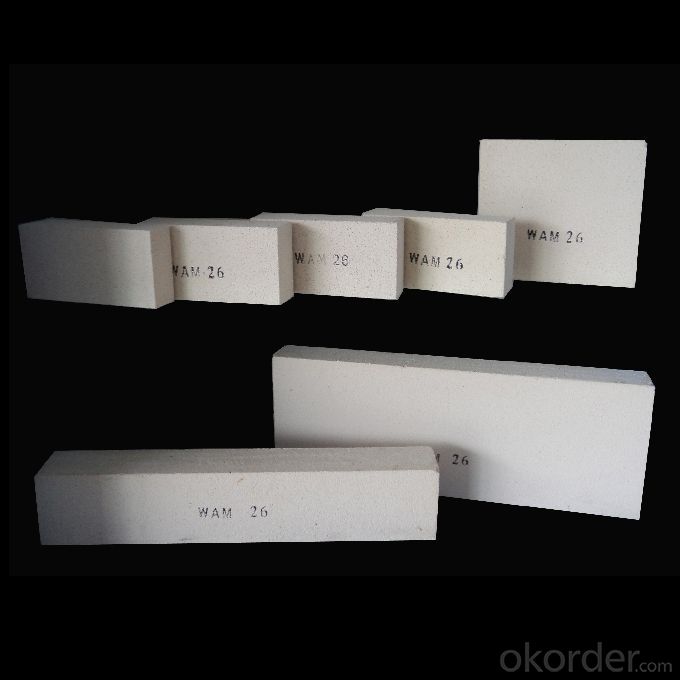

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: What is the price of fireproof insulation material?

- Fire insulation materials are various, different specifications, grades of prices are different, according to market rules, there will be fluctuation, the most commonly used are insulation rock wool, insulation board, insulation bricks, fire blocking materials.

- Q: Can insulating fire bricks be used in the construction of tundishes?

- Insulating fire bricks are indeed applicable for tundish construction. They possess exceptional thermal insulation qualities and are lightweight, which makes them perfect for situations that demand heat retention. Tundishes, utilized in the steel industry to regulate molten metal flow, necessitate materials capable of enduring high temperatures while minimizing heat loss. Insulating fire bricks excel in this area, successfully enduring extreme temperatures within tundishes, thereby safeguarding the desired molten metal temperature and preventing heat loss. Moreover, their lightweight nature facilitates uncomplicated handling and installation during tundish construction. In conclusion, insulating fire bricks prove to be a suitable choice for tundish construction due to their thermal insulation qualities and ability to withstand high temperatures.

- Q: Are insulating fire bricks resistant to high-velocity gases?

- In general, insulating fire bricks possess resistance to high-velocity gases. These bricks are specifically designed with high thermal resistance and low thermal conductivity, rendering them suitable for situations where exposure to elevated temperatures and gases is prevalent. Without experiencing any damage or compromise, they are capable of enduring the force and speed of gases. In the realm of industrial furnaces, kilns, and other high-temperature settings, insulating fire bricks find common application, as they fulfill the dual role of insulation and safeguard against high-velocity gases.

- Q: Can insulating fire bricks be installed in both industrial and residential settings?

- Yes, insulating fire bricks can be installed in both industrial and residential settings. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for a variety of applications. In industrial settings, insulating fire bricks are commonly used in furnaces, kilns, and ovens, where they help to conserve energy and maintain consistent temperatures. In residential settings, they can be used in fireplaces, wood-burning stoves, and pizza ovens, where they improve heat retention and enhance safety. Insulating fire bricks are versatile and durable, making them a reliable choice for both industrial and residential installations.

- Q: How do insulating fire bricks affect the overall sustainability of a structure?

- Insulating fire bricks play a crucial role in enhancing the overall sustainability of a structure. These bricks are designed to have low thermal conductivity, which helps in minimizing heat loss from the building. By providing effective insulation, they contribute to energy efficiency by reducing the need for excessive heating or cooling. This, in turn, leads to lower energy consumption and reduced carbon emissions, making the structure more environmentally friendly. Furthermore, insulating fire bricks have excellent durability, enabling them to withstand high temperatures and extreme conditions, resulting in longer-lasting structures that require fewer repairs and replacements. Overall, insulating fire bricks enhance the sustainability of a structure by improving energy efficiency and durability, leading to reduced environmental impact and long-term cost savings.

- Q: Can insulating fire bricks be used in fireplace construction?

- Yes, insulating fire bricks can be used in fireplace construction. They are designed to withstand high temperatures and provide excellent insulation, making them a suitable choice for building fireplaces.

- Q: Can insulating fire bricks be used as a backup insulation material?

- Yes, insulating fire bricks can be used as a backup insulation material. Insulating fire bricks are designed to have a high thermal resistance and low thermal conductivity, making them suitable for providing insulation in high-temperature applications. They can be used as backup insulation behind other refractory materials to enhance insulation properties and improve the overall thermal efficiency of a system.

- Q: Are insulating fire bricks suitable for insulation in cryogenic applications?

- Insulating fire bricks are indeed appropriate for insulation in cryogenic applications. These bricks are crafted from lightweight refractory materials that possess exceptional thermal insulation qualities. With their low thermal conductivity, high melting points, and ability to withstand extremely frigid temperatures, they are perfectly suited for cryogenic applications. Cryogenic applications entail the handling and storage of materials at exceedingly low temperatures, typically below -150 degrees Celsius (-238 degrees Fahrenheit). Insulating fire bricks are specifically designed to provide efficient insulation in such extreme conditions, effectively preventing heat transfer and maintaining the desired low temperature. Moreover, insulating fire bricks exhibit chemical stability and possess excellent resistance to thermal shock. This means they can endure rapid temperature fluctuations without cracking or deteriorating, which is particularly crucial in cryogenic applications where such variations are commonplace. In addition to their exceptional thermal insulation qualities, insulating fire bricks are lightweight and easy to handle, making them convenient for installation in cryogenic systems. All in all, insulating fire bricks are a suitable choice for insulation in cryogenic applications due to their thermal insulation properties, resistance to high temperatures, chemical stability, and ability to withstand thermal shock.

- Q: Can insulating fire bricks be used in the construction of glass melting furnaces?

- Yes, insulating fire bricks can be used in the construction of glass melting furnaces. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in the extreme heat of glass melting processes. Their low thermal conductivity helps to retain heat within the furnace, improving energy efficiency and maintaining a stable melting environment.

- Q: What is the typical creep resistance of an insulating fire brick?

- The typical creep resistance of an insulating fire brick is high, as it is designed to withstand high temperatures without deforming or sagging over time.

Send your message to us

Insulating Fire Brick - Refractory Mullite GJM32

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords