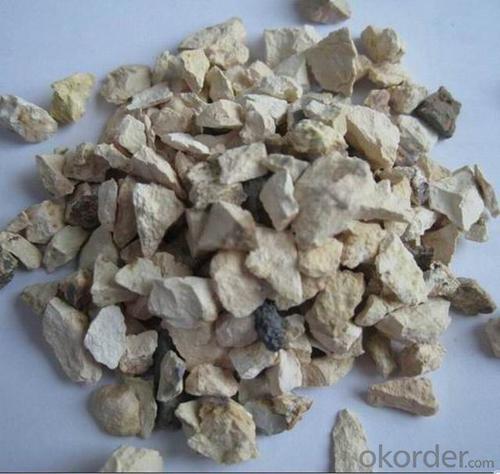

Raw Materials for Refractory:Calcined Bauxite 75-90 Grade Size 1-3mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shanxi, China (Mainland) | Shape: | Block | Material: | Alumina Block |

| SiO2 Content (%): | <8% | Al2O3 Content (%): | 75%-90% | MgO Content (%): | <0.5 |

| CaO Content (%): | <0.5 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0.0 |

| SiC Content (%): | 0.0 | Model Number: | 75,80,85,86,87,88,90 | Brand Name: | CNBM |

| Fe2O3: | 3.0 max | K2O+NA2O: | 0.3 max | TIO2: | 0.4 max |

| CaO+MgO: | ≤0.5 | shapes: | granula and powder | bulk density: | ≥2.70 |

| H.S.code: | 2508300 | Moisture: | 0.03% max | color: | yellow,black and white granula and powder |

| application: | abrasive ,cement ,chemical, metallurgical, and refractory and so on |

Packaging & Delivery

| Packaging Details: | 25kg/Bag,1Mt/Bag,1.25Mt/Bag; Or as per Client's request |

| Delivery Detail: | 7-15 days upon receipt of prepayment by TT or L/C |

Specifications

Calcined bauxite:

14 years producing experience;

self-owned mines;

SGS or BV report.

Calcined bauxite specification:

Grade | AL2O3 | FE2O3 | TIO2 | K2O+Na2O | CaO+MgO | Bulk density |

75 | 75min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.70 |

80 | 80min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.80 |

85 | 85min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.00 |

86 | 86min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.10 |

87 | 87min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.20 |

88 | 88min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

90 | 90min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | |

Size: as buyer’request

Packing: usually we packing in big bag, 1.25mt/bag; we could pack as buyer’request

Calcined bauxite is one of the principal ore of aluminum. Calcined bauxite contains hydrous aluminum oxides and aluminum hydroxides, formed through the laterization of aluminous rocks in tropical and subtropical areas .calcined bauxite is obtained by calcining (heating)superior grade bauxite at high temperature (from 85OC to 1600C) .this removes moisture thereby increasing the alumina content. compared to an alumina content of about 57%to 58%in raw bauxite, calcined bauxite has an alumina content of 84%to88%.the heating is carried out in rotary kilns.

Applications

calcined bauxite is typically calssified according to its intended commercial application,such as abrasive ,cement ,chemical, metallurgical, and refractory .as raw material for use in high alumina and super duty refratory bricks and shapes ,plastics ,castable refratory, motors, gun mixes, ramming mixes, abrasive grains and other products.

- Q: How much is refractory spraying coatings?

- Price: 1400.00 yuan refractory spraying coating brand / model: Jinshi fire resistant material| Brand: Jinshi fire resistant materials | Place of production: Henan refractory temperature: 1200 ~ 1400 (℃) | Material: Customization according to your needs Price: 2150.00 yuan refractory spraying coating brand / model: Tagore | thermal conductivity coefficient (at room temperature): 0.035W / (m · k) | refractory temperature: 1580~1770℃(℃)Price: 122.00 yuan refractory spraying coating brand / model: Jinshi | Tensile strength: | Compressive strength: tearing strength: Excellent | Temperature: 1000 ℃ | Form: Fibrous The above prices obtained from the Internet are for reference only, and please pay attention to the purchasing price.

- Q: How long usually will the A-level fireproof materials prevent the flame?

- The classification of A-level materials is based on GB8624 - 2006 building materials and products combustion performance of grading method. Specific technical requirements are: 1, temperature ≤30 degrees; mass loss rate ≤50%; continuous burning time is 0; 2, the gross calorific value of main components, overall products, external non-substantial components ≤2.0MJ / kg; any internal non-substantial component ≤1.4MJ / kg;

- Q: What kind of refractory materials are used in metallurgy industry?

- Argon-blowing rod, siliceous dry vibrating materials, desulfurizer, slag-stopping ball, stainless steel thermal insulating agent with high efficiency, dry vibration material, sizing nozzle heat-insulating panel, chrome refractory , refractory carstables for ladles, magnesia carbon refractory, package castable, siliceous drainage agent, tundish block, iron trough, deoxidizer, compound deoxidizer,silicon manganese alloy , stemming, floating plug,slagging agent. The main materials are as follows: recarburizer, covering agent, intermediate frequency furnace burden, mould fluxes, insulation thin slag agent, skimmer repair material, joint sealant.

- Q: What kind of materials can be tested their electrical resistivity in the current refractory industry?

- fused cast bricks, fused zirconia corundum blocks, corundum, high zirconium

- Q: The development prospect of fire-resistant material

- Exported bulk material amounts to exported raw material/ To protect domestic resources, many countries have set linitations on the magnesium content in shapeless refractory material and lisences.

- Q: What are the main components of refractory cement?

- Refractory cement, also known as aluminate cement, can also be gray. Aluminate cement is often yellow or brown. Aluminate cement takes bauxite and limestone as raw materials, alumina content of about 50% as the clinker. And it is a hydraulic cementing material made by grinding. The main mineral of aluminate cement is mono calcium aluminate (CaO · Al2O3, abbreviated CA) and other aluminates, and a small amount of dicalcium silicate (2CaO · SiO2), etc.

- Q: What are Grade-A waterproof inorganic thermal insulation materials?

- There is a market confusion in Grade-A waterproof inorganic thermal insulation materials. The products mainly include Grade-A monomer material like roc wool and ultra-thin insulation board and Grade-A composite material. Many Grade-B materials wraaped with calcium silicate board or foam cement belongs to Grade-A material, such as phenolic aldehyde composite. Some foamed materials with filling also belongs to Grade-A material. However, there are few products with Grade-A qualification. Many manufacturers are working on the margins of the records with Grade-A fireproofing performance examining report. But this situation will not be too long.

- Q: What are the main characteristics of the sic refractories?

- 1. The usage temperature of silicon carbide refractory is generally 1760 ℃ 2. The silicon carbide refractories can withstand dramatic changes in temperature, and a good thermal shock resistance performance. To prevent the cracking or breaking of lining refractories. 3. Under the conditions of high or low temperature, it can withstand a certain compressive stress. 4. Under the conditions of high or low temperature, it can withstand friction. 5. It can withstand the huge hydraulic pressure or buoyancy of the metal. 6. It can also withstand the effect of furnace gases to prevent the infiltration of other refractories and reactions.

- Q: Graphite and other carbon materials may be oxidized to CO or CO2 at high temperatures. But why can they be refractories?

- There is no contradiction for this. Any substance can be combustible, but different materials have different ignition points.There are many types of graphite. Pyrolytic graphite has a much lower ignition point. Therefore, as long as it reaches at a certain temperature, it can convert into graphite. Mostly, in practical applications (such as brake pads will add a certain amount of graphite), graphite is required to have refractoriness of below 1000 ℃. Graphite can serves as both the combustible and refractory material. So, it can be used as a fire-resistant and high-temperature-resisrant material because graphite (lamellar graphite) has a ignition point of at least 3000 degrees in an oxygen free condition. The above information is for reference only and is offered by Xin Ruida Graphite Company.

- Q: Refractory inquiries

- Aluminosilicate refractory refractory material refers to SiO2-Al2O3 as the main ingredient, according to how much the Al2O3 content can be divided into semi silica (Al2O3 15~30%), clay (Al2O3 30~48%), high alumina (Al2O3 > 48%) three.

Send your message to us

Raw Materials for Refractory:Calcined Bauxite 75-90 Grade Size 1-3mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords