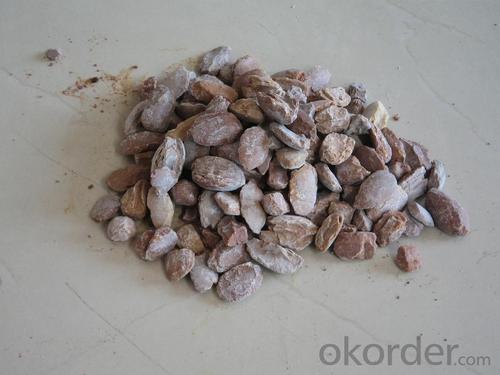

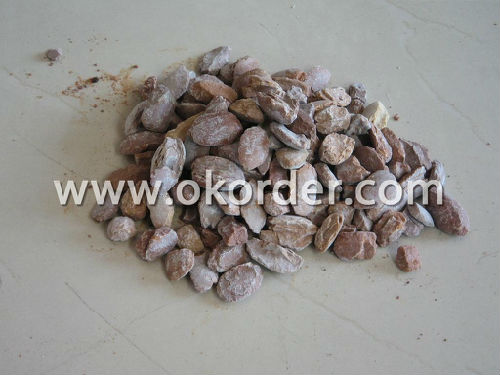

Raw Materials for Refractory:Dead Burnt Magnesite

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Dead Burnt Magnesite:

Dead Burnt Magnesite is selected from natural magnesite, calcined temperature and the shaft kiln. It is the material of ordinary magnesia bricks, shaped and unshaped refractory products.

Specifications of Dead Burnt Magnesite:

Specification(%) | ||||||

Brand | MgO min. | LOI max. | SiO2 max. | CaO max. | Fe2O3+Al2O3 max. | B.D.G/cm3 min. |

DBM90 | 90.00 | 1.00 | 4.50 | 2.50 | 3.00 | 3.1 |

DBM-95 | 95.00 | 0.30 | 3.00 | 2.00 | 1.30 | 3.15 |

DBM-97 | 97.00 | 0.20 | 0.7 | 1.3 | 0.90 | 3.25 |

DBM-972 | 97.2 | 0.2 | 0.6 | 1.3 | 0.9 | 3.27 |

DBM975 | 97.5 | 0.1 | 0.6 | 1.2 | 0.8 | 3.28 |

Applications of Dead Burnt Magnesite:

Mainly used in processing raw materials of different particle size to create a variety of magnesia refractory,

more used openhearth furnace for the production of steel lining the bottom and ramming mixes;

manufacturing the raw materials of magnesia brick and magnesiachrome brick ;

used electric steelmaking furnace, heating furnace, non-ferrous metals blowing converter furnace the bottom and the lining of the refractory materials.

Advantages:

1.We can control the quality and cost due to our strong capacity and cash flow in China .

2. We have strict and mature quality and logistics control on the cargo .

3.As a governmental company, we are reliable.

- Q: What are included in wall fireproofing material?

- External wall thermal insulation materials are divided into A and B according to combustion level. Grade A is incombustible material, while grade B is combustible material. A few years ago, fires in CCTV building and Shenyang hotel resulted from grade B material. Currently grade A is usually used, and some are even cheaper than the grade B material. Grade A is roughly divided into insulation mortar, phenolic board, rock wool board, foam cement board, etc. Insulation mortar is quite good. It is easy and convenient to construct, has low cost, but the production is too simple and it is easy to fake. It is recommend to find a large manufacturer with complete formalities, such as provincial records of production, provincial records of use, city records, type test report at or above the provincial level, national fireproof report and design drawing collection of department of construction. Lack of any is unsafe. It is recommended to use mortar from Hebei Qizheng Haocheng New Building Material Co., Ltd. It is absolutely large manufacturer. MPC thermal mortar produced by it is recommend product of Department of Construction in Hebei Province!

- Q: What's the fire endurance of fire windows?

- That is fire resistance rating, fire-resistant time in the case of fire! It can be basically classified into the following levels and the fire endurance of the fire window is as follows as well: A class fire window: no less than 1.2h; B class fire window: no less than 0.9h; C class fire window: no less than 0.6h. This is in accordance with the latest specification of gb16809-2008 fire windows.

- Q: Does the production of refractory belong to advanced technology?

- Refractories belong to the area of new materials which is one of the eight areas that are supported by the state. Whether it can be declared as high-tech enterprises or not depends on the intellectual property, personnel and finance of the company.

- Q: The following statement is correct: artificial corundum has a high melting point and can be used as a high grade refractory material. The main component is silica dioxide

- 1. corundum is the main component of alumina. 2. agate is the main component of silica. 3. is right. 4. glass is silicate. 5. solar cells are made from monocrystalline silicon. So 3.5 correct, choose D.

- Q: What's the B grade fireproofing material?

- B1 grade ceiling material: gypsum board, fobrous plasterboard, cement particle board, mineral wool decorative acoustic panels, glass wool decorative acoustic board, perlite decorative acoustic board, flame retardant plywood, flame retardant medium density fiberboard, rock wool decorative sheet, flame retardant wood, aluminum foil composites, flame retardant phenolic laminate, aluminum foil glass fiber reinforced plastic composite material, etc.; B1 grade wall material: gypsum board, fibrous plasterboard, cement particle board, mineral wool board, glass wool board, perlite board, flame retardant plywood and medium density fiberboard, fireproof plastic decorative sheet, nonflammable double-sided particle board, multicolor coating, flame retardant wallpaper and wall cloth, flame retardant simulated granite decorative plates, magnesium oxychloride cement prefabricated wall panels, flame retardant glass fiber reinforced plastic plates, PVC plastic clapboards, high-strength and lightweight composite wallboards, fire-retardant molded wooden composite boards, flame retardant colored artificial boards, nonflammable glass fiber reinforced plastics, etc.

- Q: Which kind of external wall fire barrier zone material is better?

- The following types are: rock wool, aerated concrete, phenolic aldehyde and foam cement rock wool fire barrier zone "rock wool board" mainly uses water-repelling rock wool board produced by pendulum method as thermal insulation layer materia, and connecting and fixing base wall by binding and nail bonding, it is composed level A non-combustible building energy efficiency thermal insulation system by plastering layer composed by plastering mortar and glass?fiber mesh and decorative mortar finishing layer or coating. Good air permeability

- Q: What are fire?ratings of wall thermal insulation material?

- External wall thermal insulation materials are divided into A and B according to combustion level. Grade A is incombustible?material, while grade B is combustible?material. A few years ago, fires in CCTV building and Shenyang hotel resulted from grade B material. Currently grade A is usually used, and some are even cheaper than the grade B material. Grade A is roughly divided into insulation mortar, phenolic board, rock wool board, foam cement board, etc. Insulation mortar is quite good. It is easy and convenient to construct, has low cost, but the production is too simple and it is easy to fake. It is recommend to find a large manufacturer with complete formalities, such as provincal records of production, provincal records of use, city records, type test report at or above the provincial level, national fireproof report and design drawing collection of department of construction. Lack of any is unsafe. It is recommended to use mortar from Hebei Qizheng Haocheng New Building Material Co., Ltd. It is absolutely large manufacturer. MPC thermal?mortar produced by it is recommend product of Department of Construction in Hebei Province! Generally speaking, the combustion of phenolic aldehyde is grade B, but it can barely reach A2 when a thin layer of mortar is wiped outside.

- Q: What parts of cement kilns are refractories used on?

- Generally they are used in cyclone, feed pipe, and duct and refractories are high-strength alkali-resistant castable, calcium silicate board, high-strength alkali-resistant brick, dome-shaped alkali resistant brick. Refractories in smoke chamber are high-alumina refractory castable, anti-skinning pouring material and calcium silicate board. Refractories in duct are high-strength alkali-resistant bricks, calcium silicate boards and steel fiber reinforced castable. Refractories in hooding parts of kiln are high strength castable high alumina and calcium silicate board. Refractories in rotary kiln are phosphate bonded high alumina brick, silmo brick, magnesia chrome brick, steel fiber reinforced castable. Refractories in grate?cooler are vault alkali brick, high alumina refractory castable, steel fiber reinforced castable and calcium silicate board. Refractory in coal burner is dedicated castable for coal burner.

- Q: who knows the fire endurance of fireproof coating?

- fireproof coating of different thickness differs in its fire endurance. Let me intrduce you as follows: The amount of time of 0.5 hours refractory thickness 0.45mm 0.79kg / m21 hr 0.9 mm 1.5kg / m21.5 hour 1.4 mm 2.3kg / m22 hr 2.0 mm 3.3kg / m22.5 h 2.8 mm 4.6 kg / m2

1. Manufacturer Overview

| Location | Tianjin,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;Japan;North America |

| Company Certifications | The Authentication certificate of Quality Management system |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 300,00 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Raw Materials for Refractory:Dead Burnt Magnesite

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100MT m.t.

- Supply Capability:

- 20000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords