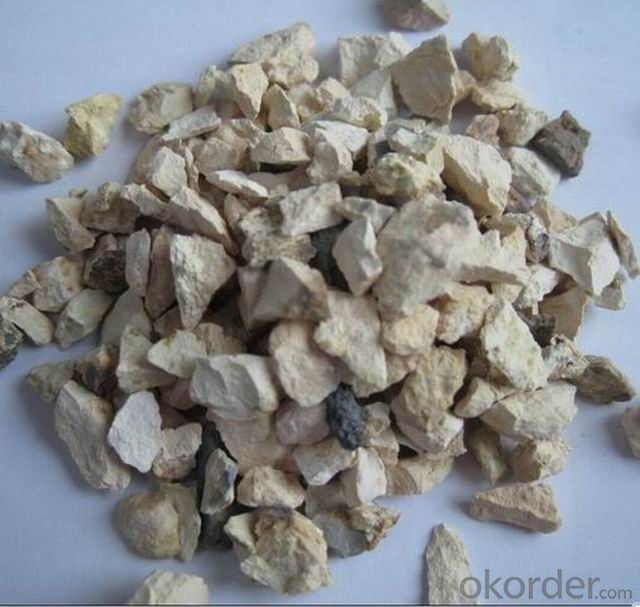

Raw Materials for Refractory:Calcined Bauxite Grade Size 1-3mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Block, block | Material: | Alumina Block |

| SiO2 Content (%): | <8%< p=""> | Al2O3 Content (%): | 75%-90% | MgO Content (%): | <0.5%< p=""> |

| CaO Content (%): | <0.5%< p=""> | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0 |

| SiC Content (%): | 0 | Model Number: | 1-3mm | Brand Name: | cnbm |

| Color: | yellow, black and white | Application: | Refractory | Moisture: | 0.03% max |

| Bulk density: | ≥2.7g/cm3 | Model Number (Grade): | 75,80,85,86,87,88,90 | Sample: | Free sample of bauxite is available |

| Fe2O3: | 3.0% max | TIO2: | 0.4 max | K2O+NA2O: | 0.3 max |

Packaging & Delivery

| Packaging Details: | 25kgs/woven bag with PE liner bag 1000kgs in a big bag |

| Delivery Detail: | 7 days |

refractory grade size 1-3mm calcined bauxite

1. Calcined Bauxite 1-3mm brief introduction:

Calcined bauxite is a mixture of minerals that contain various concentrations of hydrated

aluminum oxides as well as impurities. The primary ore minerals are gibbsite (alumina tri-hydrate), boehmite and diaspore (alumina monohydrates).

2. Different grades calcined Bauxite 1-3mm tech datas:

Grade | AL2O3 | FE2O3 | TIO2 | K2O+Na2O | CaO+MgO | Bulk density |

75 | 75min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.70 |

80 | 80min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.80 |

85 | 85min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.00 |

86 | 86min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.10 |

87 | 87min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.20 |

88 | 88min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

90 | 90min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

3. Sizes available:

Grain size : 8-5mm, 5-3mm, 3-1mm, 1-0mm

powder: -320mesh, -280mesh, -240mesh, -200mesh,

-180mesh, -150mesh, -120mesh, -100mesh

320F 200F 280F 240F

200F 80F 150F 100F

4. Calcined Bauxite 1-3mm applications:

Aluminum smelting

Precision casting

Refractory products

Grinding materials

- Q: What does fire-resistant insulation coating have?

- Refractory thermal insulation material mainly refers to the inorganic thermal insulation material and composite thermal insulation material. According to the shape, it can be divided into: Finishing of fibrous shape, mineral?cotton, rock wool, glass wool, aluminum?silicate?wool, ceramic fiber, etc. Diatomaceous earth of microporous pile, calcium silicate, expanded perlite,expanded vermiculite,aerated concrete, etc. Foam glass of bubble shape, volcanic ash glass, foamed clay, foamed?concrete, gelatine powder polyphenyl granule heat insulating slurry of pasty form, etc. Their common feature is fire-retardant and firproof. It can be used in buildings with high requirements of fire?rating. Calcium silicate, aluminum silicate and asbestos can also be used for piping insulation of heat transport with high temperature.

- Q: who knows the fire resistant levels of fireproofing glass?

- Fireproofing glass is a kind of special glass which can keep its integrity in the regular fire resistance test, and it can be divided into three classes: fireproofing glass,fireproofing glass A class is a kind of fireproofing glass that can satisfy the requirements of refractory integrity, fire resistance and thermal insulation. Including composite flameproof?glass and perfusion type fireproofing glass . This kind of glass has the properiyies of transmittance, fireproofing ( smoke insulation, fireproofing, and keeping out thermal radiation), sound insulation, shock resistance, and it's suitable for steel and wooden fire door of building decoration, windows, varnishing, partition walldaylighting?roof,ceiling?screen,perspective floor and other construction components demading for transparency and fireproofing. Class B, it's a kind of fireproofing glass that can satisfy the requirements of refractory integrity, refractory and thermal insulation at the same time. Such kind of fireproofing glasses mostly are composite fireproofing glasses and has characteristics of transmittance,fireproofing and smoke insulation. Class C, it's a kind of monolithic fireproofing glass that only satisfies the requirements of refractory integrity. This kind of glass has characteristics of transmittance, fireproofing, smoke insulation and high strength,etc. It's suitable for fireproofing glass partition wall, fire Windows, outside curtain wall and other places without insulation requirements. hope it can help you.

- Q: Who knows what is the standard of insulation material whose fire proof is level A?

- Level A is distinct from B in coefficient of fire proofing. Level A is non combustible, while Level B is divided into B1( flame retardant), B2(combustible) and B3( inflammable). Currently in the market, level A materials are as follows: phenolic, rock wool, insulation mortar, ceramic foam, foam glass, and foamed concrete. The most advantageous of level A material at present is foamed concrete, also known as foamed cement. Xuzhou Lvchuang Construction company is working on this, you can search fro it on the internet, it has high cost performance.

- Q: How to determine the fire resistance rating of the aluminium-plastic?panel?

- The fire resistance rating of the aluminium-plastic?panel is determined by two indicators, namely national compulsory standard of GB8624 "Building Materials Combustion Performance Grading Method ", and GB/T17748 "Aluminium-plastic?Composite Panel National Standard" . Classifications of combustion performance of building materials in our country are as follows: A class: Incombustible building materials; B1 class: Flame-retardant building materials; B2 class: combustible building material; B3 class: flammable building materials. The fire resistance rating of the aluminium-plastic composite panel shuld be no less than B1 class. 1. Detection indexes and requirements of fireproof aluminum-plastic composite panel (B1 class): (1) Conduct the test according to GB/T8625-88, the average leftover length of each test specimen should be more than 150mm, (any test piece should have leftover length), and the maximum average flue gas temperature of each test should be no more than 200 ℃; (2) Conduct the test according to GB/T8626-88, flame hight indicators.

- Q: how is the high-temperature flame-retardant fibre board?

- The market is mainly divided into three kind of fiber. Density fiberboard, medium density fiberboard, high density fiberboard. Density fiberboard: It is rolled timber sheet made of wood shaving material produced by timber or non timber fiber that is added with or without glue or auxiliary material. A density of less than 450 kg / cubic meter, the larger fiber particles, the internal structure is not homogeneous, relatively lack of strength, lighter weight. MDF: use wood fiber or other plant fiber as material, added with glue. A sheet pressed at high temperature and pressure. A density between 450-880 kg / cubic meter, fiber particles is moderate, well proportioned internal structure, greater strength, moderate weight. HDF: Use wood fiber or other plant fiber as material, added with glue. A sheet pressed at high temperature and pressure. Its density is about 880 kg / cubic meter, small fiber particles, well proportioned internal structure, greater strength, greater weight. there are also artificial boards such as chipboard and melamine board in the market, generally used for making furnitures. the thickness of fiberboard that is produced and controlled more flexibly, is generally 5 per cent (general bulk price of 30 yuan per square meter), 9 cm (50 yuan), 18 cm (100), 25 cm (120), etc. There are thicker. However, proper deviation is acceptable. The board is usually thicker or thinner than the specified thickness. For example, It is only 16mm when specified 18mm.

- Q: I would like to ask a friend that how much is the fire endurance of level A fireproofing glass?

- Fireproofing doors can be divided into Class A, Class B and Class C by the fire endurance, the fire endurance is seperately not less than 1.20h, 0.90h and 0.60h. Fireproofing glass is a kind of special glass which can retain its integrity and insulation in the prescribed fire test, it can be divided into three categories according to fire resistance rating: class A is the fireproofing glass with refractory integrity and refractory thermal insulation. Such glass has the properties of transmittance, fireproofing (smoke insulation, fire insulation, heat radiation shielding), sound insulation and shock resistance, which is suitable for architectural steel and wood fire doors, windows, partition walls, daylighting?roof, ceiling?screen, perspective floor and other building components required both transparent and fireproofing. Class B is a fireproofing glass with refractory integrity and thermal radiation intensity. Such fireproofing glass is mostly composite fireproofing glass with transmittance, fireproofing and smoke insulation. Class C is a fireproofing glass with refractory integrity. Such glass has the features of transmittance, fireproofing, smoke insulation and high strength. it can used in partition wall, fire window and outdoor curtain wall without the thermal insulation requirements. fireproofing glass can be divided into composite fireproofing galss and monolithic fireproofing glass by the structure.

- Q: What are the chemical composition of refractory cement?

- Calcium aluminate prepared by calcining as the main component. Aluminate cement takes bauxite and limestone as raw materials, alumina content of about 50% as the clinker. And it is a hydraulic cementing material made by grinding. Refractory cement is also known as aluminate cement.

- Q: What is refractory aggregate?

- It includes two categories: coarse aggregate and fine aggregate.

- Q: What's the commonly used refractory material for ladle?

- 1. According to the refractoriness, it can be classified as follows: common refractory: 1580℃ ~ 1770℃; high grade refractory: 1770℃ ~ 2000℃; superrefractory: 2000 ℃; 2. According to the shape and demension of the product, it can be classified as follows: standard form : 230mm×113mm ×65mm of no more than four measuring scale, (demension ratio) Max: Min

Send your message to us

Raw Materials for Refractory:Calcined Bauxite Grade Size 1-3mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords