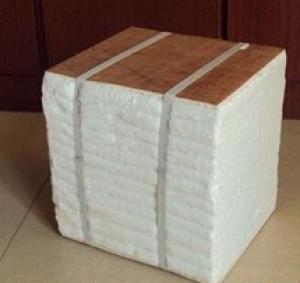

Refractory Ceramic Fiber Module For Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Ceramic Fiber ModuleAlumina fiber module with matched mechanical anchor fixings,ceramic fibre products, ceramic fiber paper, c

Ceramic Fiber Module Description:

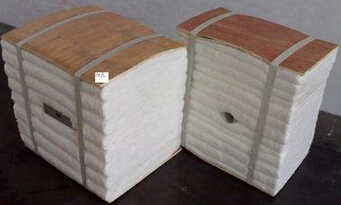

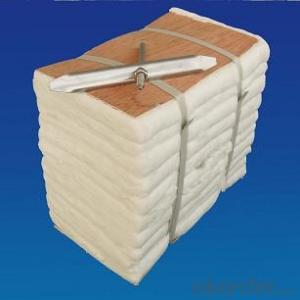

Ceramic Fiber ModuleAlumina fiber modulewith matched mechanical anchor fixings, ceramic fibre products, ceramic fiber paper, cermic fiber board,Ceramic fiber modules specialized manufacturer in CHINAAlumina fiber moduleis a new refractory lining product in order for simplifying and speeding up the furnace construction and improving the lining integrity. The product, pure white, normal size, can be directly fixed on the anchor bolt of industrial furnace steel sheet, with a good fireproof and thermal insulation, which increase the furnace refractory insulation integrity and improve the furnace lining technology. Its classification temperature (From 1050°Cto 1600°C).Product Features of ceramic fiber module:

- Excellent chemical stability

- Excellent thermal stability

- Excellent flexibility, the module is in pre-compression state, after the lining masonry

- The Expansion of modules enable seamless lining,fiber lining can be compensated to improve

- Insulation performance of Fiber lining, and the overall performance is good

- Excellent thermal stability and thermal shock resistance

- Ceramic fiber modulecan be installed quickly, and anchors set in the wall lining , which can lower the requirements of anchor Material

Ceramic fiber module typical Applications :

- Furnace lining and insulation of furnace in Petrochemical industry

- Furnace lining and insulation of furnace in Metallurgical industry

- Furnace lining and insulation of furnace in Ceramics, glass and other building materials industry

- Furnace lining and insulation of heat treatment furnace in heat treatment circle

- other industrial furnace lining

Ceramic fiber module technical Data :

| Type | Common | Standard | Zirconium | |

| Classification temperature (°C) | 1260 | 1260 | 1400 | |

| Shrinkage on heating (%) | 950°C×24h≤-3 | 1000°C×24h≤-3 | 1350×24h≤-3 | |

| Thermal conductivity by mean tem.(W/m.k)(200kg/m3) | 200°C | 0.050~0.060 | ||

| 400°C | 0.095~0.120 | |||

| 600°C | 0.160~0.195 | |||

| Density (kg/m3) | 200 | |||

| Size (mm) | 300×300×250 | |||

| Package | carton | |||

| Certificate | ISO9001-2000; ISO14001-1996 | |||

- Q: What are the production methods of calcium silicate board material?

- The two reaction method (also called combined method) is the most complete and easy to obtain process of high temperature, light weight and high strength calcium silicate products and calcium silicate boards, but its disadvantages are long process, high energy consumption and large investment.

- Q: What is the maximum temperature at which the glass is cured?

- Glass is softened at a temperature of 600 degrees. When making glass, but ordinary alcohol lamp is enough to soften it. Glass is not crystal. The softening point of lead glass is 500 degrees. The main component of ordinary glass is CaO: Na2O: 6SiO2, which can be softened by fire. In addition to the ordinary glass, glass wire, alcohol burner 1000 degree glass has no definite melting point and freezing point, in softening products can be made into any shape, so there is no fixed melting point, clarification, fluoride special glass based raw materials, slightly higher than 1200 DEG C melting, but the softening point, as well as borate, limestone, mixed melt in glass kiln.

- Q: What is the difference between calcium silicate board and cement fiber board?

- Fiber cement pressure plate is cement, fiber and other raw materials, after pulping, molding, thousands of tons of press. Calcium silicate board is made of silica and calcium plus fibrous material after pulping and formed by chemical reaction in high temperature environment. Therefore, the difference between the two is very large, mainly in the following aspects:1, from raw materials, calcium silicate board and fiber cement pressure plate difference is mainly calcium silicate board cement content is little, with sand and fly ash instead of cement.2, fiber cement pressure plate is a physical product, calcium silicate board is a chemical product.3, fiber cement pressure plate has press, calcium silicate board has no press; calcium silicate board has autoclaved Fu, fiber cement pressure plate no..4. The density of the fiber cement pressure plate is higher than that of the calcium silicate board, the density of the fiber cement pressure plate is above 1.5g/cm3, and the density of the calcium silicate board is about 1.2g/cm3.5, fiber cement pressure plate thickness can do 2.5-100mm, calcium silicate board can not do less than 4mm of ultra-thin plates and more than 30mm super thick plate, general calcium silicate board manufacturers can only do 6-12mm thickness.6, the normal production of fiber cement pressure plate color is cement color, calcium silicate board color is white.

- Q: The ceiling of calcium silicate board and mineral wool board which is good

- Mineral wool board ceiling is different than the calcium silicate board ceiling.Or with the calcium silicate board, mineral wool board first big thickness, increase the keel pressure, easy to cause the ceiling of the cave. Second, it is easy to produce some bug mineral wool board.

- Q: What are the three major effects of fly ash in concrete?

- Fly ash "micro aggregate effect" in the fly ash particle size is very small beads and debris in cement can be the equivalent of unhydrated cement grains, tiny beads equivalent to nano material and lively, can significantly improve and enhance the structural strength of concrete and improve the homogeneity of products, and compactness.

- Q: Cement is not silicate products

- Usually refers to silicate products with lime (calcium containing materials) and sand, fly ash, slag (siliceous materials), then add a small amount of gypsum, the steam steam curing or steam curing, building products quickly generate Tobey mullite, calcium silicate, hydrated calcium aluminate sulfate and hydrated calcium aluminate such as cementitious materials and production. Such as: autoclaved fly ash (sand), autoclaved aerated concrete, autoclaved fly ash brick, autoclaved sand lime bricks.

- Q: Why is calcium silicate board unsuitable for use in home improvement?

- Calcium silicate board is calcium silicate gypsum board, mainly with gypsum. At present, mainly 600*600MM, mostly used as large space, clear keel ceiling. But the family area is small, makes the Ming keel, the cost is high, also does not look well. This is why most families use a ceiling ceiling panels (gypsum board, calcium silicate board) ceiling.

- Q: What are the new energy-saving building materials? What's new?

- As far as its varieties are concerned, the new wall materials mainly include bricks, blocks and slabs, such as clay hollow bricks, waste clay bricks, non clay bricks, building blocks, aerated concrete, light plates and composite boards.

- Q: What are the main use of lime?

- A rigid inorganic cementitious material consisting mainly of calcium oxide. Lime is made from limestone, dolomite, chalk and shell with high content of calcium carbonate and calcined at 900~1100 DEG C. Lime is one of the earliest cementitious materials used in human life. Lime is widely used in civil engineering and can be used in medicine in our country.

- Q: Eterpan with calcium silicate is sold on the market are the same thing? Non asbestos calcium silicate board is Eterpan it

- Eterpan is calcium silicate board there is a famous brand. Non asbestos calcium silicate board has many kinds, Aitken is just one.

Send your message to us

Refractory Ceramic Fiber Module For Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches