Non-asbestos Calcium Silicate Board Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

100%non-asbestos calcium silicate board price

Introduction:

It is made from wood lengthy fiber, concrete and silicon sand, under the high pressure water vapor process. Therefore, it performs well in humidity durability, force resistant and fireproof. Yute fiber cement board is suitable for indoor partition, ceiling and decoration.

Our fiber cement board presents the art of Germany know-how as a high quality building material. It contains inorganic raw materials such as cement, silica powder and reinforced cellulose fiber as the main materials. All our boards are autoclaved to become stable products. It does not contain any asbestos fiber; however, it has strong bending strength like those with asbestos.

It can be applied not onlyin the interior use but also in the outdoor walls. It has low water absorption rate and high impact resistant ability. These advantages make it suitable for any purposes of applications.

Specifications:

1) 100% non-asbestos

2) Density: 1,000 - 1,400kg/cbm

3) Coefficient of thermal expansion: 0.24W / MK (JC/T54)

4) Bending strength: Over 13MPa (GB/T7019-1997)

5) Linear expansion rate: 0.1%

6) Water absorption rate: Less 0.19% (GB/T7019-1997)

7) Water penetration rate: 0%

8) Water content: 10%

9) Incombustibility according to CNS 6532 and BS 476

10) 2.5-3 hours of fire rating for (6mm wall system with W-CSP concrete)

11) Radioactivity: Standard (GB6566-2000)

12) Nonflammability: Grade A (GB-8624-1997).

Features

1) Heat insulation, stability, damp-proof, sound insulation, fire resistant and light weight

2) The wall is solid and firm inside, and resistant to impact pressure

3) Painting, tiling and nailing is possible in the new system

4) Noise reduction can be up to 46dB

5) Good efficiency

6) Working environment can keep it dry and clean for better management

7) Certificates with 2.53 hours of fire rating

8) Applications: fiber cement board can be used for partitions, interior walls, pipeline conduit compartment, stair space, exterior walls, ceiling boards as well as pillar wrapping

Our products

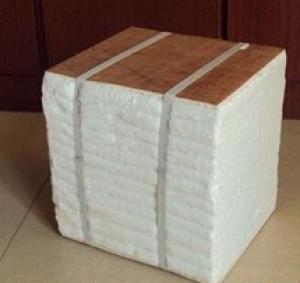

Package

- Q: Calcium silicate board for house ceiling, 6mm or 8mm?

- Calcium silicate board with fire prevention, moistureproof, sound insulation, thermal insulation, indoor air in wet conditions can attract water molecules in air, air drying, and the release of water molecules, can adjust the indoor humidity, dry, increase comfort. Natural gypsum products and special fireproof material, the flame can produce endothermic reaction, at the same time, the release of water molecules to prevent the fire from spreading, and does not produce any toxic decomposition, corrosive and choking gas, will not produce any smoke or combustibles.

- Q: The ceiling of calcium silicate board and mineral wool board which is good

- Calcium silicate board with fire prevention, moistureproof, sound insulation, thermal insulation, indoor air in wet conditions can attract water molecules in air, air drying, and the release of water molecules, can adjust the indoor humidity, dry, increase comfort.Natural gypsum products and special fireproof material, the flame can produce endothermic reaction, at the same time, the release of water molecules to prevent the fire from spreading, and does not produce any toxic decomposition, corrosive and choking gas, will not produce any smoke or combustibles.Mineral wool board is mineral fiber cotton as raw material, the biggest characteristic is to have good sound absorption and heat insulation effect.

- Q: What heat preservation material is used for thermal insulation of steam pipe in power plant? How thick is the bag? Please advise!

- Superfine glass wool insulation rockwool, steam pipe rubber board, aluminum silicate, calcium silicate products, such as polyurethane insulation form, in the application, to see the price, there are commonly used rock wool and polyurethane, rubber board, the price is relatively low, the thickness of rock wool 65, is the most thin.

- Q: What are the new energy-saving building materials? What's new?

- Mainly include new wall materials, insulation materials, waterproof sealing materials, ceramic materials, new chemical materials, decoration materials and various industrial waste residue comprehensive utilization.

- Q: What are the raw materials of cement products? What's the function?

- Cement has a great influence on the properties of concrete. The kinds and quantities of cement containing minerals and the fineness of cement will affect the quality of cement products. The calcium silicate three in cement is an important factor in the coagulation of cement products. The reaction between three calcium silicate and water leads to the production of hydrated calcium silicate, and the hydrated calcium silicate gel acts as a cementing agent for aggregate and aggregate in concrete.

- Q: What are the main use of lime?

- A rigid inorganic cementitious material consisting mainly of calcium oxide. Lime is made from limestone, dolomite, chalk and shell with high content of calcium carbonate and calcined at 900~1100 DEG C. Lime is one of the earliest cementitious materials used in human life. Lime is widely used in civil engineering and can be used in medicine in our country.

- Q: What is the best price for the use of calcium silicate ceiling?

- Neither calcium silicate nor silicate boards are afraid of water because they are mixtures of gypsum and fiber.

- Q: What's the use of low carbon steel insulated nail hooks for power plants?

- Low carbon steel nail insulation (aka: insulation pins) material: low carbon steel wire for power plants or stainless steel wire products: insulation nail. Hook nail is a power plant by mechanical processing of special insulation nail models: nail diameter: 3 mm with 3.5mm with 4 mm with 5 mm with 6 mm etc.

- Q: What is the main role of fly ash added in concrete products?

- The later strength of concrete can be improved by adding fly ashThe experimental data show that when the concrete is mixed with fly ash, the early strength (28 days ago) decreases with the increase of fly ash content, while the latter strength increases gradually. Fly ash has three effects on the strength of concrete: reducing water consumption, increasing cement content and increasing strength through long-term volcanic ash reactions.

- Q: What is dew point of thermal insulation material?

- Thermal insulation materials are generally used to guide heat coefficient less than or equal to 0.2 of the material. Thermal insulation material development is very fast, and in industry and building the use of good insulation technology and materials, often can get twice the result with half the effort. Each ton of mineral cotton insulation used in the building saves one ton of oil a year.

Send your message to us

Non-asbestos Calcium Silicate Board Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords