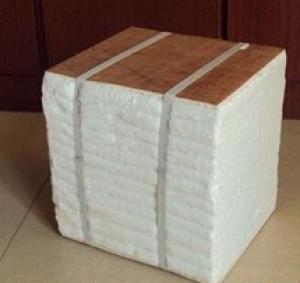

Calcium Silicate Board (650℃)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 m3 m³

- Supply Capability:

- 500m3 Per Month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Calcium silicate board 650℃

Calcium silicate board is an asbestos-free thermal insulation product that can withstand continuous operating temperature up to 1100. It is light weight, low thermal conductivity, high strength, easy to install, reliable and durable.

There are 2 grades available namely 1000 & 1100 which are commonly used as furnace backup insulation in steel, petrochemical, ceramic, cement, glass industry and fire protection in building construction.It not only provides energy saving, also increases production efficiency and gives personnel protection in industrial safety aspect.

CMAX Calcium silicate board 650℃ have good performance with the following feature:

Free-asbestos

High temperature resistance

High strength

Low thermal conductivity

Non-wetting

Thermal shock resistance

Very good machining property

Technical Data

CNBM Calcium silicate board 650℃ are available in a wide range of application:

Calcium Silicate Boards can be easily machined to precision components, and widely used in Non-ferrous metals casted, found, glass field and steel industry, so the boards are suitable for the use as Down Spouts, Shutter Rod, Floats, Linning, Riser Inserts, Sprue Bush and other precast shapes.

- Q: What is the maximum temperature at which the glass is cured?

- There is no definite melting point. Ordinary glass is a substance which is made up of soda ash, calcium silicate and silicon dioxide, and Shi Yinghe feldspar is the main raw material.

- Q: What is the difference between calcium silicate board and cement fiber board?

- Fiber cement pressure plate is cement, fiber and other raw materials, after pulping, molding, thousands of tons of press. Calcium silicate board is made of silica and calcium plus fibrous material after pulping and formed by chemical reaction in high temperature environment. Therefore, the difference between the two is very large, mainly in the following aspects:1, from raw materials, calcium silicate board and fiber cement pressure plate difference is mainly calcium silicate board cement content is little, with sand and fly ash instead of cement.2, fiber cement pressure plate is a physical product, calcium silicate board is a chemical product.3, fiber cement pressure plate has press, calcium silicate board has no press; calcium silicate board has autoclaved Fu, fiber cement pressure plate no..4. The density of the fiber cement pressure plate is higher than that of the calcium silicate board, the density of the fiber cement pressure plate is above 1.5g/cm3, and the density of the calcium silicate board is about 1.2g/cm3.5, fiber cement pressure plate thickness can do 2.5-100mm, calcium silicate board can not do less than 4mm of ultra-thin plates and more than 30mm super thick plate, general calcium silicate board manufacturers can only do 6-12mm thickness.6, the normal production of fiber cement pressure plate color is cement color, calcium silicate board color is white.

- Q: The ceiling of calcium silicate board and mineral wool board which is good

- Calcium silicate board with fire prevention, moistureproof, sound insulation, thermal insulation, indoor air in wet conditions can attract water molecules in air, air drying, and the release of water molecules, can adjust the indoor humidity, dry, increase comfort.Natural gypsum products and special fireproof material, the flame can produce endothermic reaction, at the same time, the release of water molecules to prevent the fire from spreading, and does not produce any toxic decomposition, corrosive and choking gas, will not produce any smoke or combustibles.Mineral wool board is mineral fiber cotton as raw material, the biggest characteristic is to have good sound absorption and heat insulation effect.

- Q: What heat preservation material is used for thermal insulation of steam pipe in power plant? How thick is the bag? Please advise!

- Steam pipe in power plant thermal insulation rock wool board thickness, according to the temperature in the pipeline to choose, the higher the temperature insulation thickness is generally 80 to 150 mm.

- Q: Calcium silicate board white ICI belongs to wood surface paint?

- No, it isn't。Calcium silicate board material properties should be comparable with cement products, usually referred to as cement board is actually calcium silicate board.

- Q: Eterpan and yinte in what is the difference?

- Calcium silicate board:Calcium silicate board is mainly inorganic mineral fiber or cellulose fiber and other loose short fiber materials with siliceous and calcareous materials as the main cementing material, pulping, molding, in high temperature and high pressure saturated steam curing acceleration, sheet formation of calcium silicate gel made.Calcium silicate board is a new type of building and industrial plate with excellent properties. Its products are fireproof, moisture-proof, soundproof, moth resistant and durable. It is an ideal decorative board for ceiling and partition. Excellent waterproof performance, just can prevent the home improvement for a long time damp deformation, especially in the bathroom for a long time in a humid environment, the use of calcium silicate board ceiling is the best choice.

- Q: What are the raw materials of cement products? What's the function?

- Sand。 Gravel occupies a very large volume in concrete production, reaching 70%~80%. The aggregate surface, structure, adsorption and water content of aggregate should be required. The appropriate amount of sand and gravel can save cement, reduce the cost of concrete production, and improve the strength of concrete.

- Q: What is the best price for the use of calcium silicate ceiling?

- The price of each place and labor costs are not the same, here in Heilongjiang labor costs about 18---20 yuan per square meter, plus keel, hanger, calcium silicate board of about 45----50 yuan per square meter.

- Q: What is the main role of fly ash added in concrete products?

- The workability of fresh concrete can be improved by adding fly ashThe workability of fresh concrete is affected by the volume, water cement ratio, gradation, shape and porosity of the aggregate. The fly ash is used for fresh concrete is the obvious benefits of increasing the slurry volume, slurry filled with aggregate between pores, inclusions and lubrication of aggregate particles, so that the concrete mixture has better cohesiveness and plasticity. The aggregate particles of fly ash can reduce the interfacial friction between the paste and aggregate, and improve the workability of the concrete mixture at the contact point of the aggregate.

- Q: What is a building energy-saving materials?

- Mainly include new wall materials, insulation materials, waterproof sealing materials, ceramic materials, new chemical materials, decoration materials and various industrial waste residue comprehensive utilization.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 1988 |

| Annual Output Value | Above US$3600 Million |

| Main Markets | North America Southeast Asia Western Europe Africa |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 40% - 50% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Installation guide, consultant,and training |

| Product Price Range | High;Average |

Send your message to us

Calcium Silicate Board (650℃)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 m3 m³

- Supply Capability:

- 500m3 Per Month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords