Refractory Ceramic Fiber Module For Boiler Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical Data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

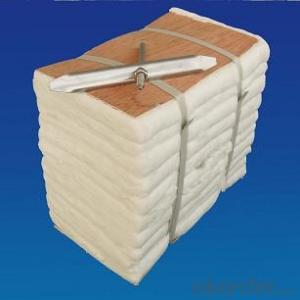

| Main Technical Property of Ceramic Fiber Module:

Note: 1. Product which is classified in accordance with temperature range, can be divided into ceramic fiber cutout, ceramic fiber module and ceramic fiber folded module by different production methods. Our factory is equipped with advanced laboratory; all the figures in the above table are from experiment. We all provide other experiment figures according to customers' requirements.

Size and Specifications of Ceramic Fiber Module:

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ceramic fiber will perform excellent refractoriness and improve the integrated thermal insulating performance of the furnace.

Characteristic: (1) Excellent refractoriness

(2) Excellent chemical stability and thermal stability

(3) Low thermal conductivity, low thermal capacity

(4) Resist to external mechanical forces

(5) Able to withstand any thermal shock

(6) Generate no gaps between modules

- Q: What kind of insulation material can withstand 350-600 degrees of high temperature?

- Suggest that you refer to the above two data to choose from, select only from the temperature, you can use

- Q: What are the high temperature resistant insulation materials at 400?

- According to the general rules of equipment and piping insulation, heat insulation material is a material with a thermal conductivity of less than 0.14W/ (m*K) when the average temperature is equal to or less than 623K (350 degrees Celsius). Heat insulation material is usually light, porous, porous, small thermal conductivity characteristics. Generally used to prevent heat loss of equipment and pipes, or frozen (also known as general cold) and low temperature (also known as cryogenic) use, so in our country, insulation materials, also known as insulation or cold preservation materials. At the same time, because of the porous and fibrous structure of thermal insulation material, it has good sound absorption function, so it is also widely used in the construction industry.

- Q: The ceiling of calcium silicate board and mineral wool board which is good

- Calcium silicate board with fire prevention, moistureproof, sound insulation, thermal insulation, indoor air in wet conditions can attract water molecules in air, air drying, and the release of water molecules, can adjust the indoor humidity, dry, increase comfort.Natural gypsum products and special fireproof material, the flame can produce endothermic reaction, at the same time, the release of water molecules to prevent the fire from spreading, and does not produce any toxic decomposition, corrosive and choking gas, will not produce any smoke or combustibles.Mineral wool board is mineral fiber cotton as raw material, the biggest characteristic is to have good sound absorption and heat insulation effect.

- Q: What heat preservation material is used for thermal insulation of steam pipe in power plant? How thick is the bag? Please advise!

- Superfine glass wool insulation rockwool, steam pipe rubber board, aluminum silicate, calcium silicate products, such as polyurethane insulation form, in the application, to see the price, there are commonly used rock wool and polyurethane, rubber board, the price is relatively low, the thickness of rock wool 65, is the most thin.

- Q: Calcium silicate board white ICI belongs to wood surface paint?

- No, it isn't。Calcium silicate board material properties should be comparable with cement products, usually referred to as cement board is actually calcium silicate board.

- Q: Why is calcium silicate board unsuitable for use in home improvement?

- It is not the appropriate material, calcium gypsum board to hemihydrate gypsum and organic silicone oil as the main material, the surface of the organic silicone oil with the installation way friction transportation will fall, a long time will get loss loss, if the poor quality of the organic silicone coating, it is not full proof effect is worse in the course of time, deformation, damp, moldy yes, yellow.

- Q: What are the new energy-saving building materials? What's new?

- As far as its varieties are concerned, the new wall materials mainly include bricks, blocks and slabs, such as clay hollow bricks, waste clay bricks, non clay bricks, building blocks, aerated concrete, light plates and composite boards.

- Q: What's the difference between white cement and ordinary cement?

- White portland cement as the raw meal with the proper components till the partial melting of the calcium silicate as the main ingredient, the iron content in clinker less addition of gypsum, white water ground made of rigid cementitious material. When grinding cement, allow limestone not to exceed 5% of the cement weight. White cement is mostly ornamental, and its manufacturing process is much better than ordinary cement. The gap is mainly used to hook white tiles, is generally not used in the wall, the reason is not high strength. It is available in the building materials market or decoration materials shop.

- Q: What is the main role of fly ash added in concrete products?

- The later strength of concrete can be improved by adding fly ashThe experimental data show that when the concrete is mixed with fly ash, the early strength (28 days ago) decreases with the increase of fly ash content, while the latter strength increases gradually. Fly ash has three effects on the strength of concrete: reducing water consumption, increasing cement content and increasing strength through long-term volcanic ash reactions.

- Q: What is dew point of thermal insulation material?

- Thermal insulation materials are generally used to guide heat coefficient less than or equal to 0.2 of the material. Thermal insulation material development is very fast, and in industry and building the use of good insulation technology and materials, often can get twice the result with half the effort. Each ton of mineral cotton insulation used in the building saves one ton of oil a year.

Send your message to us

Refractory Ceramic Fiber Module For Boiler Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords