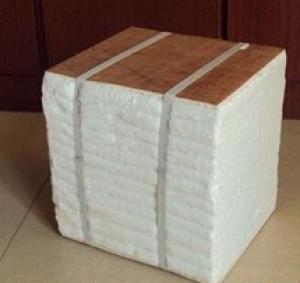

High Quality Refractory Ceramic Fiber Block

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Refractory Ceramic Fiber Block1Ceramic fiber moduleceramic fiber factory

2ISO, MSDS

3Density:190-220kg/m3

| Product Information | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The leading ceramic fiber brand in china specialist in exportation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Refractory Ceramic Fiber Block is made from the corresponding ceramic fiber material acupuncture blanket processed in dedicated machines according to fiber component structure and size. In the process, a certain proportion of compression is maintained, in order to ensure modules expand to the different directions after completion of ceramic fiber folded module wall lining, to create mutual extrusion amongst modules and form a seamless whole unit. Ceramic fiber folded modules is directly fixed in industrial furnaces furnace shell plate by various anchorage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Brief Introduction | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Technical Data | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Quality can meet the European Standards | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: Asbestos free calcium silicate board there is a crack in the kettle, what is the reason?

- Calcium silicate slab blank (blank off off phenomenon is not forming tube adhesion fingerboard blank above)There are two reasons: one is the blank off the vacuum negative pressure is too large, the blank water is too low, low viscosity; two is felt blocked, the billet made worse.The solution is to reduce the negative pressure, strengthen the cloth washing.

- Q: What's the difference between white carbon and carbon black? Can they be replaced?

- White carbon black in color rubber products instead of carbon black reinforcing, meet the needs of the white or translucent product. Anti aging performance of silica with strong adhesion force, tearing resistance and heat, so the black rubber products can replace part of the carbon black, in order to obtain high quality rubber products, such as off-road tires, engineering tire, radial tire.

- Q: What are the high temperature resistant insulation materials at 400?

- Thermal insulation materials for thermal equipment and pipes are mostly inorganic insulation materials. This kind of material has the characteristics of no decay, no burning, high temperature resistance and so on. For example: asbestos, diatomite, perlite, glass fiber, foam glass concrete, calcium silicate and so on.

- Q: The ceiling of calcium silicate board and mineral wool board which is good

- Calcium silicate board with fire prevention, moistureproof, sound insulation, thermal insulation, indoor air in wet conditions can attract water molecules in air, air drying, and the release of water molecules, can adjust the indoor humidity, dry, increase comfort.Natural gypsum products and special fireproof material, the flame can produce endothermic reaction, at the same time, the release of water molecules to prevent the fire from spreading, and does not produce any toxic decomposition, corrosive and choking gas, will not produce any smoke or combustibles.Mineral wool board is mineral fiber cotton as raw material, the biggest characteristic is to have good sound absorption and heat insulation effect.

- Q: What's the use of white portland cement?

- All the raw meal with the proper components up to the partial melting of the calcium silicate as the main ingredient, the iron content in clinker less addition of gypsum, white water ground made of rigid cementitious material, called white portland cement (the white cement).When grinding cement, allow limestone not to exceed 5% of the cement weight.Note: cement is allowed to be added to the grinding mill without damaging the cement properties. The amount of cement added shall not exceed 1% of the cement weight. The addition of additional substance must be tested and reported to the Ministry of construction materials for approval.

- Q: Eterpan and yinte in what is the difference?

- Eterpan:Eterpan, is a kind of fiber reinforced silicate plate (fiber cement board), the main raw material is cement, plant fiber and minerals, the flow of high temperature steam pressure and slurry method, mainly used as building materials.Eterpan is a kind of high strength, durability and other advantages of fiber silicate sheet, with various thickness and density, 100% does not contain asbestos and other harmful substances. For non combustible A1 grade products.The utility model has the advantages of fire prevention, moisture proof, waterproof, sound insulation effect, environmental protection, quick installation, long service life, etc.. Often used for wall panels, bathroom partitions, outdoor roofing, roofing, exterior insulation panels, interior decoration, ceilings, etc.; alsoInstead of gypsum board, used as base material in decoration.

- Q: What are the raw materials of cement products? What's the function?

- Cement has a great influence on the properties of concrete. The kinds and quantities of cement containing minerals and the fineness of cement will affect the quality of cement products. The calcium silicate three in cement is an important factor in the coagulation of cement products. The reaction between three calcium silicate and water leads to the production of hydrated calcium silicate, and the hydrated calcium silicate gel acts as a cementing agent for aggregate and aggregate in concrete.

- Q: What are the main use of lime?

- Lime milk and mortar, slaked lime or lime paste, with lots of paint. Lime mortar or slaked lime powder can be used to prepare lime mortar or cement lime mixture mortar for masonry or plastering engineering.

- Q: Eterpan with calcium silicate is sold on the market are the same thing? Non asbestos calcium silicate board is Eterpan it

- Aitken is a brand of non asbestos calcium silicate board is a product name

- Q: What is a building energy-saving materials?

- As far as its varieties are concerned, the new wall materials mainly include bricks, blocks and slabs, such as clay hollow bricks, waste clay bricks, non clay bricks, building blocks, aerated concrete, light plates and composite boards.

Send your message to us

High Quality Refractory Ceramic Fiber Block

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords