Rebaring in Concrete with HRB 400-500 Hot Rolled Deformed Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Rebars at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Label: to be specified by customer, generally, each bundle has 1-2 labels

Product Advantages:

OKorder's Hot Rolled Rebars are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: HRB400 – HRB500

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Grade | Technical data of the original chemical composition (%) | ||||||

C | Mn | Si | S | P | V | ||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physical capability | |||||||

Yield Strength (N/cm²) | Tensile Strength (N/cm²) | Elongation (%) | |||||

≥400 | ≥570 | ≥14 | |||||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m bar(kg) |

6 | 28.27 | 0.222 | 2.664 |

8 | 50.27 | 0.395 | 4.74 |

10 | 78.54 | 0.617 | 7.404 |

12 | 113.1 | 0.888 | 10.656 |

14 | 153.9 | 1.21 | 14.52 |

16 | 201.1 | 1.58 | 18.96 |

18 | 254.5 | 2.00 | 24 |

20 | 314.2 | 2.47 | 29.64 |

22 | 380.1 | 2.98 | 35.76 |

25 | 490.9 | 3.85 | 46.2 |

28 | 615.8 | 4.83 | 57.96 |

32 | 804.2 | 6.31 | 75.72 |

36 | 1018 | 7.99 | 98.88 |

40 | 1257 | 9.87 | 118.44 |

50 | 1964 | 15.42 | 185.04 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What is the normal tolerance of Hot Rolled Mild Steel Angle Beams for Structures and for Buildings?

A3: Normally 3%-5%, but we can also produce the goods according to the customers' requests.

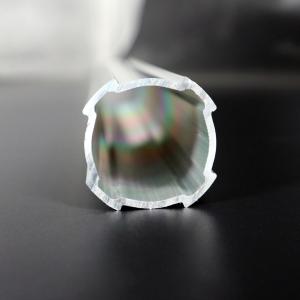

Images:

- Q:Can steel rebars be used in aggressive chemical environments?

- Steel rebars can be used in aggressive chemical environments to some extent. However, their performance may be compromised depending on the severity and nature of the chemicals present. Steel rebars are generally resistant to mild to moderate chemical exposures, such as those found in most construction applications. However, in highly aggressive chemical environments, where exposure to corrosive substances like acids, alkalis, or salts is prolonged and intense, steel rebars may corrode and deteriorate over time. In such cases, alternative materials like stainless steel rebars or epoxy-coated rebars may be more suitable, as they provide enhanced resistance to corrosion in aggressive chemical environments. It is important to consider the specific conditions of the chemical environment and consult with experts or structural engineers to determine the most appropriate rebar material for the given situation. Regular inspections and maintenance should also be conducted to monitor the condition of steel rebars and ensure their longevity in aggressive chemical environments.

- Q:What is the tensile strength of different grades of steel rebars?

- The tensile strength of different grades of steel rebars can vary depending on the specific grade. Generally, steel rebars range in tensile strength from 400 to 600 megapascals (MPa) for lower grade rebars, while higher grade rebars can have tensile strengths ranging from 600 to 900 MPa or even higher.

- Q:What is the process of deforming steel rebars for better adhesion with concrete?

- The process of deforming steel rebars for better adhesion with concrete is known as ribbing or rib deformation. This process involves creating small ridges or raised patterns along the surface of the rebar, which enhances the bond between the concrete and the steel. The ribbing process is typically performed through a mechanical operation called cold rolling. Cold rolling is a metalworking process where the steel rebar is passed through a series of rollers, which exert pressure on the surface and cause plastic deformation. The rollers are designed with specific patterns or configurations that create the desired ribbing on the rebar. The purpose of ribbing is to increase the surface area of the rebar in contact with the concrete. The ridges or patterns created by the ribbing process provide additional points of adhesion for the concrete to grip onto, significantly improving the bond strength between the two materials. This enhanced bond is crucial for reinforcing concrete structures, as it helps to distribute loads and resist tensile forces. The ribbing process is commonly used in the construction industry for reinforcing concrete structures such as beams, columns, and slabs. The specific pattern and depth of the ribbing may vary depending on the project requirements and the type of rebar being used. Manufacturers often adhere to industry standards and guidelines to ensure the proper design and placement of ribbed rebars. In summary, the process of deforming steel rebars for better adhesion with concrete involves ribbing or creating ridges on the rebar's surface. This is achieved through cold rolling, where the rebar is passed through rollers designed with specific patterns. Ribbing increases the surface area and provides additional points of adhesion, improving the bond between the concrete and the rebar.

- Q:How do steel rebars affect the overall structural integrity of a building?

- Steel rebars play a crucial role in enhancing the overall structural integrity of a building. By reinforcing and strengthening concrete structures, rebars effectively distribute loads and resist tension, preventing cracks and structural failures. This reinforcement enables buildings to withstand various forces, such as earthquakes and high winds, ensuring their stability and durability over time.

- Q:What are the best practices for handling and storing steel rebars on a construction site?

- The best practices for handling and storing steel rebars on a construction site include: 1. Properly storing the rebars on a flat and well-drained surface to prevent damage and rust. 2. Keeping the rebars off the ground using pallets or other suitable supports to avoid contact with moisture. 3. Organizing the rebars by size, type, and length to ensure easy access and minimize handling risks. 4. Securing the rebars with tie wires or rebar caps to prevent any accidental displacement. 5. Providing adequate space and clear signage to avoid any tripping or safety hazards. 6. Regularly inspecting the rebars for any signs of rust, deformation, or damage and removing any defective ones from use. 7. Lifting and moving rebars with appropriate equipment, such as cranes or forklifts, to avoid strain or injuries. 8. Keeping the rebars protected from inclement weather conditions by covering them with tarps or waterproof materials. 9. Training and educating construction workers on proper handling techniques and safety protocols related to steel rebars. 10. Adhering to local regulations and industry standards for the storage and handling of steel rebars.

- Q:How are steel rebars used in the construction of chemical processing plants?

- To reinforce and strengthen chemical processing plants, steel rebars are commonly employed. These rebars, also known as reinforcing bars, are typically crafted from carbon steel and are utilized to fortify various concrete structures like foundations, walls, columns, and beams. Considering the handling of hazardous and corrosive substances in chemical processing plants, the infrastructure is subjected to significant stress. Therefore, the utilization of steel rebars is of utmost importance as it safeguards the integrity of the structures and mitigates the risk of collapse or failure. When constructing chemical processing plants, it is customary to embed steel rebars within the concrete to create a reinforced concrete structure. This amalgamation of concrete and steel rebars forms a composite material that possesses augmented tensile strength, enabling it to endure the heavy loads, vibrations, and extreme temperature fluctuations frequently encountered in chemical plants. Furthermore, the deployment of steel rebars aids in averting cracks and structural deformations caused by shrinkage, settling, or external forces. This is particularly critical in chemical processing plants, where maintaining a secure and stable environment is imperative for employee safety and the plant's operational integrity. Moreover, steel rebars exhibit exceptional resistance to corrosion, a crucial attribute in chemical processing plants where exposure to corrosive chemicals and high humidity levels is prevalent. By serving as a protective barrier for the underlying concrete, steel rebars effectively prevent deterioration induced by corrosion, thereby prolonging the lifespan of the structures and reducing maintenance expenses. Overall, the presence of steel rebars assumes a vital role in the construction of chemical processing plants as they ensure structural stability, durability, and corrosion resistance, all of which are essential for the safe and efficient functioning of these facilities.

- Q:Can steel rebars be used in tunnel lining construction?

- Tunnel lining construction readily employs steel rebars, given their exceptional tensile strength and durability. These rebars are extensively utilized as they furnish structural reinforcement to the concrete lining, assuring its stability and long-term performance. Typically, the rebars are embedded within the concrete lining, creating a robust composite structure that effectively withstands the various loads and pressures encountered in tunnel environments. Moreover, steel rebars can be easily molded and flexed to conform to the tunnel's shape, facilitating efficient and precise construction. Overall, steel rebars represent an indispensable element in tunnel lining construction, guaranteeing the essential strength and structural integrity that safeguard the safety and longevity of the tunnels.

- Q:How do steel rebars affect the overall load distribution of concrete structures?

- Steel rebars significantly affect the overall load distribution of concrete structures by providing tensile strength and reinforcing the concrete. The rebars absorb and distribute the applied load throughout the structure, reducing the risk of cracking and enhancing the structural integrity. Without rebars, concrete structures would be more prone to failure under heavy loads or external forces.

- Q:Are steel rebars resistant to chemicals?

- Steel rebars are typically resistant to chemicals. Steel is renowned for its strength and durability, enabling it to endure exposure to various chemicals without significant deterioration. However, the level of resistance may vary based on the specific chemical, concentration, and duration of exposure. Generally, steel rebars exhibit high resistance to commonly found construction materials and environments, including water, concrete additives, and standard cleaning agents. They also withstand acids, alkalis, and organic solvents. Nevertheless, aggressive chemicals like strong acids or oxidizing agents can lead to corrosion or damage over time. Therefore, it is crucial to consider the chemical environment when choosing and utilizing steel rebars, and implement appropriate safeguards if necessary, such as protective coatings or corrosion inhibitors.

- Q:How do steel rebars contribute to the fire resistance of concrete?

- Concrete's fire resistance is enhanced by steel rebars in several ways. Firstly, steel rebars possess a non-combustible nature and a high melting point, ensuring they do not burn or add fuel to fires. This characteristic aids in preventing the spread of fire and maintaining the concrete's structural stability during fire incidents. Additionally, steel rebars act as reinforcement within the concrete, boosting its overall strength and load-bearing capacity. This reinforcement effectively prevents cracking or fragmentation of the concrete under high temperatures caused by fire. The presence of steel rebars also enhances the concrete's ductility, enabling it to deform and absorb energy during fires, rather than abruptly shattering or collapsing. Moreover, steel's thermal conductivity surpasses that of concrete, enabling it to effectively conduct heat away from the fire zone. This assists in dissipating heat and preventing it from reaching critical levels that could compromise the concrete's structural integrity. By absorbing and distributing heat, steel rebars contribute to slowing down the temperature rise within the concrete during fires. In conclusion, steel rebars contribute to concrete's fire resistance by providing structural stability, improving strength and load-bearing capacity, enhancing ductility, and dissipating heat. These attributes make concrete structures reinforced with steel rebars more resilient, enabling them to withstand fires for extended periods. As a result, the safety of occupants is increased, and potential property damage is reduced.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rebaring in Concrete with HRB 400-500 Hot Rolled Deformed Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords