Rail Track Reinforcement Geogrids - Biaxial Water-Soluble PVC Coated Polyester Geogrid 40*40KN PP Biaxial Plastic Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geogrid:

40*40 KN PP Biaxial Geogrid

Subgrades reinforcement

The BX geogrids can effectively spread the loads to larger layers and so leads to a reduction of construction thickness and an extented pavement life---3 times longer than before. In addition, the BX geogrids provide a proven and practical solution to improving the brearing capacity of reciprocating loads while lowering the harms on the pavement. According to the test data, the reinforced subgrade with BX geogrids can have as more than 3 times bearing capacity concerning reciprocating loads as it had without reinforcement.

Specifications of biaxial(BX) geogrid | ||||||

properties | unit | TGSG | TGSG | TGSG | TGSG | TGSG |

unit weight | g/m2 | 300±30 | 330±30 | 400±40 | 500±50 | |

roll width | m | 4.00±0.20 | ||||

Tensile strength(MD) ≥ | KN/m | 15 | 20 | 30 | 40 | 45 |

Tensile strength(CD) ≥ | KN/m | 15 | 20 | 30 | 40 | 45 |

Elongation(MD) ≤ | % | 13 | 13 | 13 | 13 | 13 |

Elongation(CD) ≤ | % | 16 | 16 | 16 | 16 | 16 |

tensile strength @2% elongation(MD) ≥ | KN/m | 5 | 8 | 11 | 13 | 16 |

tensile strength @2% elongation(CD) ≥ | KN/m | 7 | 10 | 13 | 15 | 20 |

tensile stength @5% elongation(MD) ≥ | KN/m | 8 | 10 | 15 | 16 | 25 |

tensile stength @5% elongation (CD) ≥ | KN/m | 10 | 13 | 15 | 20 | 22 |

Applications of Geogrid:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Property of Geogrid:

1.) Improve roadbed bearing capacity,enlarge road lifetime.

2.) Prevent road collapse and crack

3.) Prevent soil and water loss in slope

4.) Could replace steel-plastic geogrid in coal mine.

Packaging & Delivery

| Packaging Details: | as customers' requirement.. |

| Delivery Detail: | 30days |

FAQ:

1. How to order your geogrid ?

a). Tensile strength in warp & weft direction

b). Grid size

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

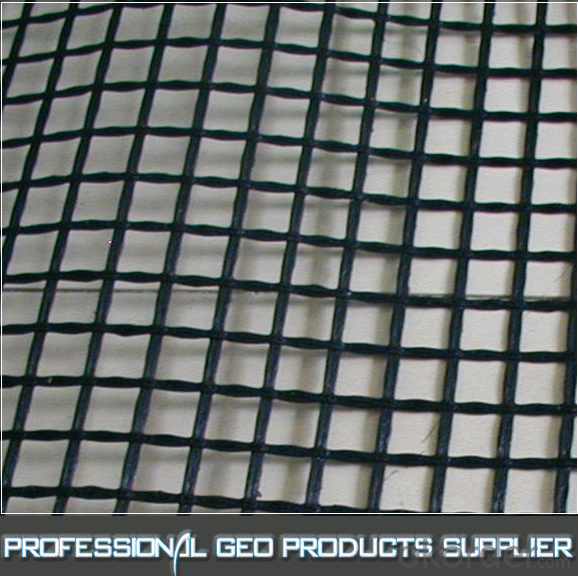

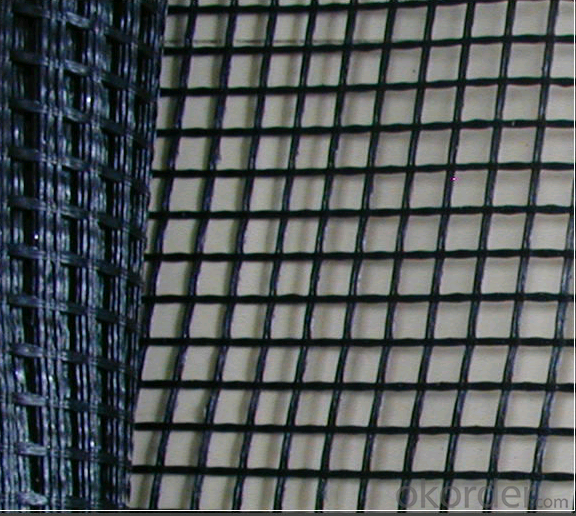

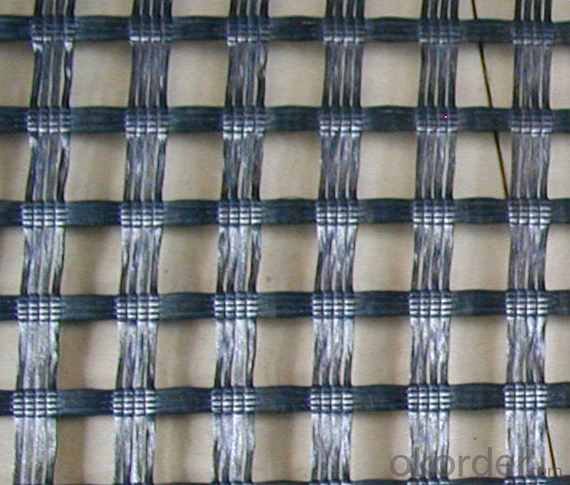

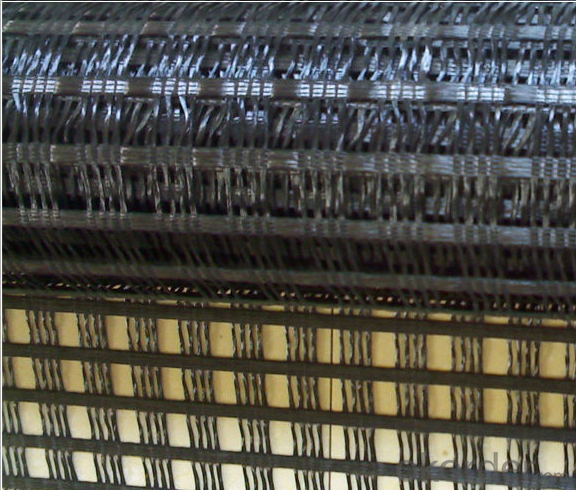

Geogrid Show:

- Q: Are there any limitations or disadvantages of using geogrids?

- Yes, there are some limitations and disadvantages of using geogrids. 1. Cost: Geogrids can be relatively expensive compared to other soil reinforcement methods. The cost of materials and installation can sometimes be prohibitive, especially for large-scale projects. 2. Limited Applications: Geogrids are not suitable for all types of soil conditions. They are most effective in granular soils, but their performance in cohesive soils or unstable slopes may be limited. 3. Installation Challenges: Proper installation of geogrids requires specific expertise and equipment. If not installed correctly, their effectiveness can be reduced, leading to potential failure or performance issues. 4. Longevity: The long-term durability of geogrids can vary depending on factors such as exposure to environmental conditions, chemical degradation, and mechanical damage. In some cases, they may require regular maintenance or replacement to ensure continued effectiveness. 5. Compatibility: Geogrids may not always be compatible with certain construction materials or methods. It is important to consider their compatibility with other materials used in the project to avoid any adverse effects on performance. Despite these limitations, geogrids are still widely used in various geotechnical applications due to their ability to improve soil stability and enhance the performance of structures.

- Q: One-way plastic geogrid TGDG120 how qualified

- D unidirectional plastic geogrid 120KN

- Q: How do geogrids improve the performance of geocell-reinforced retaining walls?

- Geogrids improve the performance of geocell-reinforced retaining walls by providing additional reinforcement and stability to the structure. They help distribute the loads more evenly, reducing the pressure on the retaining wall and preventing excessive deformation. Geogrids also increase the overall strength and durability of the wall, enhancing its ability to withstand lateral forces and maintain its shape over time.

- Q: Are geogrids suitable for reinforcing landfill liners?

- Yes, geogrids are suitable for reinforcing landfill liners. They are commonly used in landfill engineering to enhance the stability and strength of liners by reducing deformation and improving load distribution. Geogrids also help to prevent soil erosion and provide long-term reinforcement, making them an effective solution for reinforcing landfill liners.

- Q: What is the difference between nonwoven geotextiles and geotextile? What is their role?

- Geomembrane is a kind of composite material. The utility model is composed of a HDPE geomembrane and a non-woven geotextile filter fabric, which is composed of a nonwoven geotextile filter +HDPE geomembrane and a non-woven geotextile filter fabric, which is compounded with a HDPE geomembrane, and has good waterproof effect.Role: River, dam, reservoir, landscape lake seepage are impervious to the material.

- Q: Can geogrids be used in reinforcement of underground pipelines?

- Yes, geogrids can be used in the reinforcement of underground pipelines. Geogrids are a type of geosynthetic material that provide additional support and stability to the surrounding soil, preventing the pipeline from experiencing excessive deformation or damage. They are commonly used in pipeline installation and rehabilitation projects to increase the overall strength and load-bearing capacity of the soil, ensuring the long-term stability and functionality of the underground pipelines.

- Q: Can geogrids be used in reinforced earth bridge abutments in liquefaction-prone areas?

- Yes, geogrids can be used in reinforced earth bridge abutments in liquefaction-prone areas. Geogrids are commonly used as reinforcement materials in geotechnical engineering to improve the stability and strength of soil structures. In liquefaction-prone areas where the soil may lose its strength and become unstable during seismic events, geogrids can provide additional support to the soil and prevent its failure. By incorporating geogrids into the reinforced earth bridge abutments, the overall stability and resilience of the structure can be enhanced, making it more resistant to liquefaction-induced damage.

- Q: How do geogrids improve the performance of geotextile-reinforced slopes for erosion control?

- Geogrids improve the performance of geotextile-reinforced slopes for erosion control by adding an additional layer of stability and strength. They provide enhanced soil confinement, preventing soil movement and erosion. This reinforcement helps to distribute the load more evenly across the slope, reducing the risk of slope failure. Additionally, geogrids increase the tensile strength of the geotextile fabric, enhancing its ability to withstand stress and maintain its integrity over time. Overall, geogrids significantly improve the erosion control capabilities of geotextile-reinforced slopes, making them more effective and durable in preventing soil erosion.

- Q: How do geogrids improve the performance of reinforced slopes?

- Geogrids enhance the performance of reinforced slopes by providing increased stability and strength. They act as a reinforcement layer within the soil, distributing loads more evenly and reducing the risk of slope failure or erosion. Geogrids also improve the soil's shear strength, preventing lateral movement and improving overall slope stability.

- Q: How does a geogrid work?

- A geogrid works by providing reinforcement and stabilization to soil or other materials. It is typically made of high-strength polymers and has a grid-like structure. When placed within the soil, the geogrid interlocks with the particles, creating a composite material that has improved load-bearing capacity. This helps to distribute forces and prevent the movement or deformation of the soil. Overall, a geogrid enhances the stability and durability of the soil structure, making it suitable for various applications such as road construction, erosion control, and retaining walls.

Send your message to us

Rail Track Reinforcement Geogrids - Biaxial Water-Soluble PVC Coated Polyester Geogrid 40*40KN PP Biaxial Plastic Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords