Race Car Body Aluminum Sheets - 1100 1050 2024 3003 5052 6061 6082 7021 Alloy Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Information:

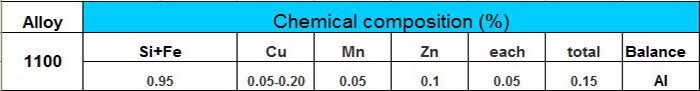

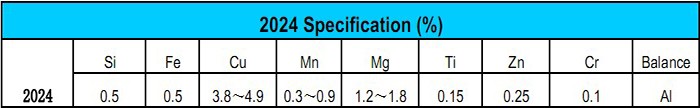

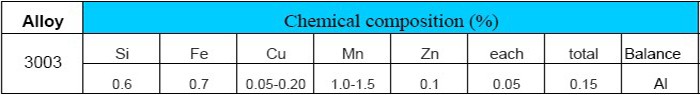

1.Alloy: 1100 1050 2024 2017 3003 5052 6061 6063 7075 7021 etc

2.Temper:O H112 H12 H14 H16 T3 T4 T6 T651 etc

3.Dimension based on customer requirements

4.Good quality choose us

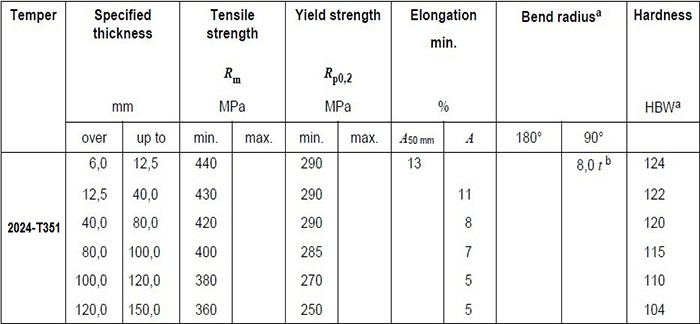

Chemical Composition:

Technical Specification:

Packaging & Delivery

| Packaging Details: | Wooden Pallet, Wooden Case, As Customzed, etc. |

| Delivery Detail: | 15 to 25 days depends on actual order |

Our Services

1) Reply within 12 hours

2) Free samples provided

3) On-site production following-up

4) Loading inspection with container fixing

5)Third party inspection at your request

Company Information

Advanced equipment and strict management both contribute to the excellent quality of products. Our main products are all kinds of cold rolling and hot rolling aluminum sheet, coil, checkered plate, embossed plate, aluminum foil, aluminum disc, aluminum profile, painted aluminum sheet and coil. Our products have various size choices with thickness from 0.008mm to 350mm, width from 200mm to 2300mm and length below 12m. Our products are sold to all over the world, including South America, North America, Europe, Middle-East, South-East Asia, Africa etc and used in various fields such as construction, decoration, automobile, electronic, machinery, boat construction, aeronautics&astronautics, cookware, packing etc.

Adhering to the principle of “ Surviving with quality and developing with credibility”, CNBM hopes to work with all customers for a better future.

FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 5 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

4) Why YONGHONG?

With us, you get most competitive price, guranteened quality with assured delivery time and after sales service

- Q: What is the most effective technique for applying a coating to aluminum sheets?

- <p>The best method for coating aluminum sheets depends on the desired application and properties of the coating. Common methods include anodizing, which provides a protective oxide layer, powder coating for a durable finish, and electroplating for enhanced corrosion resistance. For decorative purposes, methods like painting or vacuum deposition can be used. Each method has its advantages and is chosen based on factors such as cost, durability, and aesthetic requirements.</p>

- Q: What kind of welding rod should be used for aluminum plate, welding and welding?.

- Aluminum plate welding, now mostly choose TIG welding, MIG welding to welding, selection of welding rod is less. If the choice of electrode welding, can recommend selection of MG400 electrode, the electrode is produced by American MG welding, gas welding and welding, can all Aluminum Alloy, good welding performance. Need to use DC welding machine, welding electrode as far as possible upright, welding speed is relatively fast, about two times the carbon steel electrode. A kilogram of electrodes is nearly seventy.

- Q: Can aluminum sheets be used in outdoor environments?

- Yes, aluminum sheets can be used in outdoor environments. Aluminum is a highly versatile and durable material that is well-suited for outdoor applications. It has excellent resistance to corrosion, which makes it ideal for withstanding the elements such as rain, snow, and UV radiation. Additionally, aluminum sheets are lightweight yet structurally strong, making them suitable for various outdoor projects such as roofing, siding, and cladding. Furthermore, aluminum is non-combustible, making it a safe choice for outdoor environments. Overall, aluminum sheets provide a reliable and long-lasting solution for outdoor applications.

- Q: Can 101 aluminum sheets be perforated?

- Indeed, it is possible to perforate 101 aluminum sheets. Perforation involves the creation of a hole pattern in a material, and aluminum is frequently chosen for this purpose due to its adaptable and sturdy nature. The inclusion of the number "101" likely denotes the alloy type or specific grade of aluminum, which has no bearing on its perforatability. Hence, accomplishing the perforation of 101 aluminum sheets is easily achievable through several techniques such as punching, laser cutting, or drilling, contingent upon the desired hole pattern and size.

- Q: Is it possible to use aluminum sheets for roofing purposes?

- <p>Yes, aluminum sheets can be used as roofing materials. They are known for their durability, lightweight, and resistance to corrosion. Aluminum is also recyclable and can be coated with various finishes to enhance its appearance and performance. It is a popular choice for both residential and commercial roofing due to its low maintenance requirements and long lifespan.</p>

- Q: What is the weight of aluminium plate now?

- Is different according to the different density of aluminum alloy content, such as a series of pure aluminum and aluminum density is 2.71, which is close to that of 1060 Aluminum, 1050.1100 series of density is 2.71. and 3003 aluminum plate belongs to the aluminum manganese alloy, manganese alloy belongs to high density alloy, so the density is higher than that of 3003 aluminum plate 1060. and 5052 series aluminum magnesium alloy, magnesium alloy alloy belongs to low density, so the density of 2.68.5083 5052 aluminium alloy aluminum magnesium alloy containing the content because of the high price (4.5%) so 5083 aluminum density of 2.66. 2 series and 7 Series (such as 7075) belongs to high density alloy (copper and zinc) so high density.

- Q: Can aluminum sheets be used for insulation?

- No, aluminum sheets alone cannot be used for insulation as they have low insulation properties. However, they can be used as a reflective layer in combination with other insulation materials to enhance insulation efficiency by reflecting heat or cold.

- Q: Can aluminum sheet be used in marine environments?

- Yes, aluminum sheet can be used in marine environments. Aluminum is a popular material choice for marine applications due to its excellent corrosion resistance. It forms a protective oxide layer on its surface, which helps to prevent further corrosion even in saltwater environments. Additionally, aluminum is lightweight, which makes it an ideal choice for marine applications where weight reduction is crucial. Aluminum sheet is commonly used in boat hulls, decks, and other marine structures due to its durability, strength, and resistance to corrosion.

- Q: What is the shear strength of 101 aluminum sheets?

- The shear strength of 101 aluminum sheets can vary depending on various factors such as the thickness of the sheet, the specific alloy composition of the aluminum, and the manufacturing process used. Generally, 101 aluminum sheets have a shear strength ranging from 20,000 to 30,000 pounds per square inch (psi). However, it is important to note that this is a general range and specific values may vary. To obtain the exact shear strength of 101 aluminum sheets, it is recommended to consult the material's technical data sheet or reach out to the manufacturer for more accurate information.

- Q: How does aluminum sheet perform in extreme temperatures?

- Due to its unique properties, aluminum sheet exhibits exceptional performance in extreme temperatures. One of its key advantages is its remarkable thermal conductivity, enabling it to efficiently transfer heat. This characteristic allows aluminum sheet to quickly adapt to extreme temperatures, preventing the occurrence of warping or cracking that may be experienced with other materials. Moreover, aluminum possesses a high melting point of approximately 660 degrees Celsius, rendering it highly suitable for usage in high-temperature environments. It remains structurally stable, retaining its strength and integrity even when subjected to intense heat. Additionally, aluminum exhibits a low coefficient of thermal expansion, resulting in minimal expansion and contraction in response to temperature fluctuations. This particular attribute enables aluminum sheet to maintain its shape and dimensions even when exposed to drastic temperature changes. Furthermore, aluminum showcases exceptional corrosion resistance, further augmented by the formation of a natural oxide layer on its surface. This oxide layer serves as a protective barrier against chemical reactions, safeguarding the aluminum from deterioration even in harsh environments or extreme temperatures. In conclusion, aluminum sheet demonstrates outstanding performance in extreme temperatures due to its high thermal conductivity, high melting point, low coefficient of thermal expansion, and excellent corrosion resistance. These properties establish it as a reliable choice for a multitude of applications, including the aerospace, automotive, and industrial sectors, where the ability to perform under extreme temperatures is of utmost importance.

Send your message to us

Race Car Body Aluminum Sheets - 1100 1050 2024 3003 5052 6061 6082 7021 Alloy Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords