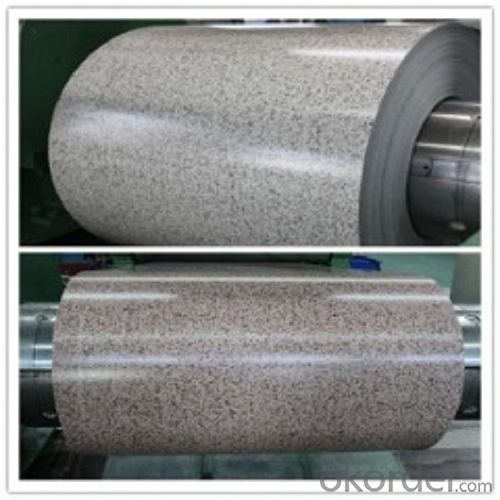

PVDF PE Coated Color Aluminum Coil for Gutter Machine ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Specifications

Painted Aluminium Coil

1) Temper: H14, H18, H24 mainly.

2) Alloy 1100, 1050, 3003,3004, 5052, 8011 etc

3) Origin: China

Painted Aluminium Coil:

1) The type of paint: PE, PVDF, PA, PU

2) Thickness coating: PVDF: More then 25 micron; PE, more then 18 micron.

3) Paint supplier: PPG (PVDF)

4) Interior diameter: Mainly in 405mm, 505, mm

5) Width: Less then 1600mm, sheets are also available

6) Color: Panton, RAL or refer to customers' counter sample.

7) Coating hardness: (pencil hardness) more than 2H

8) Impact resistance: No cracking and peeling (50kg/cm, ASTMD-2794: 1993)

9) Flexibility (T-bend): No more than 2T

10) MEK resistance: More than 100

The base of Painted Aluminium Coil details:

1) Temper: H14, H18, H24 mainly.

2) Alloy 1100, 1050, 3003, 3004, 3005, 5052, 8011 etc

3) Origin: China

4) MOQ: 5 tons each size

5) Lead Time: Within 20 days

6) The term of payment: T/T, irrevocable L/C at sight

7) Application: Curtain wall, roof, internal and external wall, ACP, Door

l Packaging & Delivery:

Packaging Details: 1.with wooden pallet packing.

2.standard fumigated wooden package.

3.other packing methods by customer's requirement.

Delivery Details: 30-40days

l Company Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 10 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email: service@okorder.com

- Q: Can aluminum coils be used in the production of consumer goods?

- Consumer goods production can indeed make use of aluminum coils. Aluminum, being a versatile and lightweight material, presents numerous benefits in the manufacturing of consumer goods. Its remarkable resistance to corrosion makes it particularly suitable for products that are exposed to moisture or outdoor conditions. Moreover, aluminum coils offer easy formability and shaping capabilities, enabling efficient production processes and customization. The utilization of aluminum is widespread in consumer goods like kitchen appliances, automotive components, packaging materials, and electronic devices. Manufacturers seeking to produce long-lasting and top-notch consumer goods find aluminum's properties to be an optimal choice.

- Q: How are aluminum coils used in the production of solar panels?

- The production of solar panels heavily relies on aluminum coils, as they perform essential functions in the construction of photovoltaic modules. These coils are primarily employed as the framing material for the PV module, offering structural support and safeguarding the delicate solar cells from external forces like weather or physical harm. Aluminum's lightweight yet robust characteristics make it an ideal choice for this purpose, as it ensures durability without burdening the overall structure with excessive weight. Additionally, aluminum coils are commonly utilized as the backsheet material in solar panels. The backsheet plays a crucial role in shielding the solar cells from moisture, dust, and other environmental elements, acting as a barrier that prevents potential damage while providing electrical insulation. Aluminum's exceptional resistance to corrosion and its electrical conductivity make it highly suitable for this application. Moreover, aluminum coils are employed in the fabrication of the interconnection system within solar panels. This system comprises conducting wires that establish connections between individual solar cells, enabling the efficient flow of electricity among them. Aluminum's high electrical conductivity ensures minimal energy losses within the panel, facilitating the effective transmission of generated electricity. Furthermore, aluminum coils find utility in the manufacturing of various other components within solar panels, including junction boxes, connectors, and mounting systems. These components contribute to the overall functionality and reliability of solar panel systems. In summary, the extensive use of aluminum coils in solar panel production can be attributed to their lightweight, durable, and corrosion-resistant properties. These coils exhibit versatility and the ability to withstand harsh environmental conditions, making them indispensable for ensuring the efficiency and longevity of solar panel systems.

- Q: In my line of work I see aluminum ground lugs, bonding nuts and straps and also neutral bars eat copper up, especially when exposed to the elements. I know how galvanic reaction works between elements under current load, but my question is why do aluminum and copper seem to hate each other more than any other? And, why would they still be required in usage together per NEC code?

- that's a single alternative reaction. The aluminum and the copper swap places, yielding copper and aluminum sulfate. Please notice: the 1st answer describes a chemical equation with nitrate, no longer sulfate. otherwise, this is the perfect format.

- Q: This question asks about the potential health impacts of aluminum coils, which are commonly used in various industries and products.

- <p>Aluminum coils themselves are generally considered safe and do not directly affect health when used in their typical applications such as construction, electrical components, or food packaging. However, there is ongoing debate about the potential health risks of aluminum exposure, particularly when ingested. Some studies suggest a link between aluminum and neurological disorders like Alzheimer's disease, though this is not conclusively proven. It's important to note that aluminum is a common element found naturally in the environment, and the human body can naturally excrete small amounts. The use of aluminum coils in food packaging is regulated to ensure safety, and the risk of aluminum toxicity from these sources is considered low.</p>

- Q: How are aluminum coils priced?

- Aluminum coils are typically priced based on various factors such as the current market price of aluminum, the size and thickness of the coil, the quantity ordered, and any additional customization or processing requirements. Additionally, factors like transportation costs and market demand can also influence the pricing of aluminum coils.

- Q: Almost every restaraunt uses aluminium foils and polyehylene for packing foods - that you carry to home.How safe is this ?For how long would the temperature be mainitained ?and within what time if consumed and is it safe ?

- I was wondering about that too; I heard it somewhere before but it's one of those things that sits in the back of my mind till i see someone wrapping food in aluminum foil, every picky bone in my body tells me to yell no don't wrap my food in that but I just don't because there is no real harm in it. Only thing is it may change the flavor of your food after while. That part I remember:)

- Q: Is it safe for individuals to handle aluminum coils?

- <p>Aluminum coils are generally safe to handle under normal conditions. They do not emit harmful radiation or toxic fumes. However, it's important to take precautions to avoid injury from sharp edges or heavy weight. Always use appropriate lifting equipment or assistance when handling heavy coils. Additionally, wear protective gloves to prevent cuts and ensure good housekeeping to avoid tripping hazards. In case of skin contact with certain aluminum processing fluids, it's advisable to wash the affected area immediately with soap and water.</p>

- Q: What are the different coil coating options for aluminum coils?

- There are several coil coating options available for aluminum coils, including polyester, polyurethane, fluoropolymer, and plastisol coatings. Each option offers unique benefits, such as durability, weather resistance, and aesthetics, allowing for customization based on specific requirements or desired appearance.

- Q: Are aluminum coils suitable for architectural louvers?

- Yes, aluminum coils are suitable for architectural louvers. Aluminum is a popular choice for louvers due to its excellent corrosion resistance, lightweight nature, and high strength-to-weight ratio. Aluminum coils can be easily formed and fabricated into various shapes and sizes, making them ideal for creating aesthetically pleasing and functional louvers. Additionally, aluminum's durability ensures that the louvers can withstand harsh weather conditions and maintain their structural integrity over time. Overall, aluminum coils are a reliable and versatile material for architectural louvers.

- Q: This question asks for methods to determine whether an aluminum coil is made from recycled material.

- <p>Determining if an aluminum coil is made from recycled material can be challenging without specific testing, as recycled and virgin aluminum can look identical. However, there are a few indicators: 1) Look for certification or labels on the coil indicating it's made from recycled material. 2) Check with the supplier for documentation or a certificate of analysis that confirms the material's origin. 3) Analyze the coil's composition; recycled aluminum may have slight variations in purity or alloy composition. 4) Use spectrographic analysis to determine the exact composition of the aluminum, which can sometimes reveal if it's recycled. Ultimately, transparency from the supplier is key to confirming the source of the aluminum.</p>

Send your message to us

PVDF PE Coated Color Aluminum Coil for Gutter Machine ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords