PVDF COLOR ZINC COATED STEEL SHEET IN COIL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

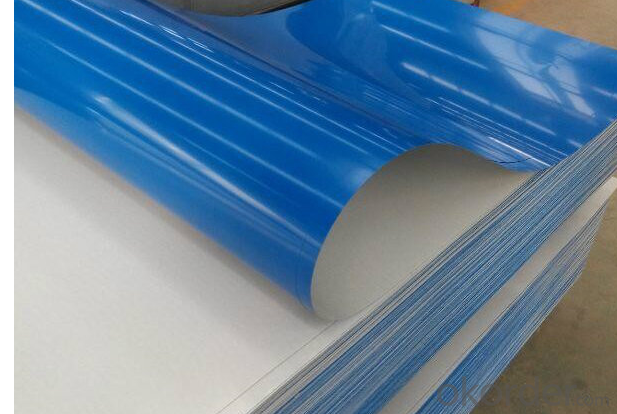

PVDF color coated zinc steel sheet incoil ,with Gi as base metal after pretreatment ( degrease and chemical treatment) and liquid dope with several layers of color then after firing and cooling finally the plate steel is called Pre-painted galvanized steel is good capable of decoration ,molding corrosion resistance

Product Features

Excellent process capability

Smooth and flat surface

Workability durability

Excellent heat resistance performance

High Strength

Good formability

Good visual effect

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

1. How long will we receive the goods ?

45days after receiving workable L/C

2. how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: in a lab at school we did heat treatment of steelwhat are the possible phases present in the steel sample in as-received, as-quenched and as-tempered conditions? specifically when is it ferrite, austenite and pearliteis the steel originally in the ferrite phase? then when headed turns into austenite and when quenched martensite is formed and when tempered cermentite is formed...........where is pearlite involved and am i correct about the ferrite?

- hey from what i learned in uni last sem, steel is originally ferrite form at first at room conditions. it will undergo poly morphic transformation to become FCC structure austenite form at 912 degree celcius. under conditions, it can become pearlite (which is a combination of ferrite and cementite) or bainitie( a finer form of pearlite). queching conditions to room temperature will form martensite which is the strongest but brittle steel form. tempered cementite is formed when we quench it and then raise temperatures before sir cooling. hope it helps, pls vote me best answer is i deserve it. thanks

- Q: How are steel coils used in the production of aerospace components?

- Steel coils are used in the production of aerospace components as they provide the necessary strength and durability required for various applications such as structural parts, fasteners, and landing gear. These coils are typically processed and formed into specific shapes and sizes to meet the design requirements of the aerospace industry.

- Q: How do the sandpaper grits compare with different coarse levels of steel wool? For example, I'm finishing a homemade entertainment center, and using a tinted polyurethane, and it says to use 000 grade steel wool, but mine is #3, could I use some sanpaper instead, and what grit?

- Steel wool and wax is for the final buff after the finish coat. Sanding will scratch the finish and should only be done before the finish coat. Steel wool and wax have been used as the final finish to remove rough areas and buff the finish for a long time.

- Q: 911 conspiacy theorists. Can fire melt steel?

- Don't know the differences in steel strength between the WTC towers and the bridge, but I'll tell you they don't always use the strongest steel in buildings. It is a question of value engineering. Engineers do as code requires, and make the determination based on economics of building. If a steel member requires say 48 KSI, with certain span, but if the price is less expensive to use 35 KSI and reduce the span by adding vertical elements then that is an option that the architects, engineers and developers consider. Like I said, don't much about bridge engineering, but in buildings, it isn't always the strongest steel, based on engineering and economics. And BTW, said time and time again, but ok one more time. STEEL DOESN'T NOT HAVE TO MELT FOR FAILURE. IT LOSES STRENGTH WITH HEAT. THAT IS WHY IT MUST BE PROTECTED BY FIRE RETARDANT. BUT IF THE FIRE RETARDANT IS REMOVED BY EXPLOSION, THEN FIRE CAN CAUSE FAILURE. Sorry for the shouting, but I'm not the only one who says that, but people keep saying steel can't melt, but it doesn't have to for failure. If the steel joist had been in concrete, the WTC towers may have stood, at least longer. But hindsight is 20/20.

- Q: How are steel coils uncoiled?

- Steel coils are typically uncoiled using a mechanical device called a decoiler. The decoiler feeds the steel coil through a set of rollers, which gradually unwinds and straightens the coil, allowing it to be used for various applications.

- Q: How are steel coils used in the production of steel springs?

- Steel coils are used in the production of steel springs as they are rolled into a specific shape and size, providing the necessary strength and flexibility required for springs. These coils are then cut and formed into the desired spring shape, allowing them to store and release energy efficiently.

- Q: Basically when i'm older, my dream Job would be, to be to start a steel mill, I've always loved the idea of working in Business and investing in things has always been a hobby of mine. i play games where u invest and make money. all i need is some facts about starting a steel mill?What requirements i need,- How time consuming is it,- How easy is it,- How to get started,- The Perks,- The downsides..how much would it cost to start one, like land, place, iron etc, to get started? also i would need a bank loan, how much money will the bank give me ? 80%??

- Typically, steel mills are worth $20 million to $200 million and are owned by large corporations. Your best bet to own one would be to take over a corporation that already has one. That way you have all the supply lines, customers, experts and other workers already there, too. Stick with investing in going concerns, so you don't need to be an expert in each business to build it up. Get them ready made, learn the details from the people already doing it, then work out ways to improve it. Do not get tempted to borrow even 10c from the scammers who have answered your question. Start saving your real money, reading the financial news, and making small real investments in real stocks.

- Q: I am looking at website on google based on the terms structural steel fabrication and simply steel fabricationI know that there must be a difference between the two terms, but it seems that many website authors use the two terms interchangeably.Do you know the key differences between the two terms?

- Structural steel is steel construction material, a profile, formed with a specific shape or cross section and certain standards of chemical composition and strength. Structural steel shape, size, composition, strength, storage, etc, is regulated in most industrialized countries. Fabrication, when used as an industrial term, applies to the building of machines, structures and other equipment, by cutting, shaping and assembling components made from raw materials. Small businesses that specialize in metal are called fab shops. Steel fabrication shops and machine shops have overlapping capabilities, but fabrication shops generally concentrate on the metal preparation, welding and assembly aspect while the machine shop is more concerned with the machining of parts.

- Q: How are steel coils annealed to improve their properties?

- Steel coils are annealed to improve their properties through a process called annealing, which involves heating the coils to a specific temperature and then slowly cooling them. This process helps to relieve internal stresses, enhance ductility and toughness, and refine the grain structure of the steel, resulting in improved mechanical properties such as increased strength and reduced brittleness.

- Q: What are the commonly used molds steel?

- floor scientific care of different types, I communicate approximately features of chilly paintings die metallic warmth scientific care: chilly paintings mold metallic alloying aspects quantity and style are plenty, alloying is quite complicated. The detrimental thermal conductivity of metallic, the austenitizing temperature is bigger, so the heating technique slowly, preheats or cascade warmth greater. to guard the floor of the metallic high quality, heating medium must be heavily, so the controlled ecosystem furnace, vacuum furnace, heating equipment and greater procedures, including person-friendly use, salt bath heating must be totally digitizing and purification. on the thought of accomplishing quenching, ought to apply a average cooling way. Isothermal quenching, interrupted quenching, intense rigidity gas quenching, including air cooling quenching is someone-friendly technique. with a view to greater strengthen, chilly scientific care, or nitriding floor scientific care has an considerable result and use. Salt bath scientific care must be well timed cleansing, technique protection paintings very heavily. chilly paintings die metallic is costly, chilly paintings mold areas processing complicated, long cycle and intense cost of manufacture. So the formula and operation technologies must be very careful, to circumvent high quality coincidence, confirm the protection of the production technique.

Send your message to us

PVDF COLOR ZINC COATED STEEL SHEET IN COIL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords