Brushed Aluminum Sheets Canada - PVDF Color Coating Aluminium Sheet for Sandwich Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of PVDF Color Coating Aluminium Sheet for Sandwich Panels

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | 0.03MM-3.0MM |

WIDTH | 30mm-1700mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE ,PVDF , EPOXY,16-25MICRON PAINTING THICK, MAX 40MICRONS |

STANDARD | GB/T 17748-1999 |

2. Application of PVDF Color Coating Aluminium Sheet for Sandwich Panels

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of PVDF Color Coating Aluminium Sheet for Sandwich Panels

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

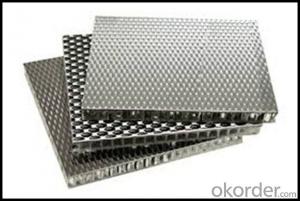

5. Image of PVDF Color Coating Aluminium Sheet for Sandwich Panels

6. Package and shipping of PVDF Color Coating Aluminium Sheet for Sandwich Panels

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are the aluminum sheets suitable for manufacturing electrical enclosures?

- Yes, aluminum sheets are suitable for manufacturing electrical enclosures. Aluminum is a highly versatile and widely used material in the manufacturing industry, including for electrical enclosures. It offers several advantages that make it suitable for this application. Firstly, aluminum is lightweight yet strong, making it ideal for constructing enclosures that need to be durable while also being easily transportable and installable. Its strength-to-weight ratio is higher than many other metals, allowing for the creation of sturdy enclosures without adding unnecessary weight. Secondly, aluminum has excellent corrosion resistance. This is crucial for electrical enclosures as they are often placed in various environments where they may be exposed to moisture, humidity, or other corrosive elements. Aluminum's natural oxide layer provides a protective barrier against corrosion, ensuring the longevity and reliability of the enclosures. Additionally, aluminum is a good conductor of electricity, which is another important characteristic for electrical enclosures. It allows for efficient dissipation of heat generated by electrical components, preventing overheating and potential damage to the enclosed devices. Furthermore, aluminum is easily machinable and can be formed into various shapes and sizes. This flexibility allows manufacturers to customize the enclosures according to specific requirements, ensuring a perfect fit for the intended electrical components. Lastly, aluminum is a cost-effective material compared to other metals like stainless steel or copper. It offers a good balance between affordability and performance, making it an attractive choice for manufacturing electrical enclosures. In conclusion, aluminum sheets are indeed suitable for manufacturing electrical enclosures due to their lightweight, strength, corrosion resistance, electrical conductivity, machinability, and cost-effectiveness.

- Q: How much is one ton of aluminium plate?

- For aluminum alloy, the aluminum alloy and other metal elements, according to different metallic elements, can be divided into eight branches, 1-8 etc.. According to the contents of various metallic elements, each department can be divided into different grades of alloy, such as 8011505230031060, each kind of alloy prices are not the same. In addition, the different processing thickness, width, the process used, the cost is not the same, so the specifications are different, the price is different. As for the aluminum plate, how much is it a ton? I think you have a better answer.

- Q: Can the aluminum sheets be used for manufacturing musical instruments?

- Musical instruments can indeed be manufactured using aluminum sheets. Aluminum, being a lightweight and versatile material, offers numerous advantages in instrument manufacturing. Its exceptional sound transmission properties are well-known, making it ideal for producing resonant and lively tones in musical instruments. Furthermore, aluminum boasts high durability and resistance to corrosion, ensuring the longevity of the instruments. Aluminum sheets are frequently used in the production of percussion instruments such as cymbals and bells due to their ability to generate clear and melodious sounds. Additionally, aluminum can be easily shaped and formed into different components, making it a popular choice for constructing brass instruments like trumpets and trombones. In conclusion, aluminum sheets are a viable and successful option in the manufacturing of musical instruments.

- Q: Can aluminum sheets be coated with other materials?

- Yes, aluminum sheets can be coated with other materials. Aluminum is a versatile metal that can be easily coated with various substances, such as paints, lacquers, polymers, and specialty coatings. These coatings can enhance the appearance, durability, corrosion resistance, and thermal or electrical properties of the aluminum sheets.

- Q: Could two pieces of aluminum sheets be welded together?

- or you can use file to rub back and forth, and it needs lots of practices or you can't weld the sheets.because aluminum sheet cann't be tightly welded to tin, it's hard to weld two pieces of aluminum sheets by common welding methods.it's hard, the aluminum sheets are oxidized soon after polished by abrasive paper.and you need to cover the new polished area with soldering paste and learn some operating skills.owing to aluminum sheets' high oxidized speed, you need to wipe the aluminum sheets with soldering paste and soldering tin and rub them with large power soldering iron, then the aluminum sheets will be tightly welded to tin.so two pieces of aluminum sheets could be welded together.

- Q: Are aluminum sheets suitable for aircraft panels?

- Yes, aluminum sheets are suitable for aircraft panels. Aluminum is widely used in the aviation industry due to its excellent strength-to-weight ratio, which makes it ideal for constructing lightweight yet strong aircraft structures. Aluminum sheets are commonly used for aircraft panels because they offer a combination of durability, corrosion resistance, and ease of fabrication. Additionally, aluminum can be easily formed and welded, allowing for complex panel shapes to be created. Furthermore, aluminum has good electrical conductivity, which is important for the proper functioning of various aircraft systems. Overall, the use of aluminum sheets for aircraft panels helps to ensure the structural integrity and performance of the aircraft.

- Q: I just built a stone wall with illuminated glass features embedded, and to make them shine evenly, I had all sides but the visual one wrapped in industrial thickness aluminium foil. One week later, the foil has disintegrated. I have used type 10 Portland. What is going on?

- Embedded aluminum roof flashing, aluminum water stops, aluminum electrical conduit, introduced aluminum powder (sometimes used to foam concrete), or embedded structural aluminum shapes may all corrode in concrete or mortar. In all cases, a reaction that forms aluminum hydroxide and hydrogen gas occurs, and may cause expansion and cracking of the concrete or mortar. The common use of calcium chloride (or other alkali compounds), and dampness of the concrete increases the reaction rate. Usually, coating the aluminum with bituminous paint, impregnated paper or felt, plastic, or an alkali-resistant coating will prevent or sharply reduce the corrosion.

- Q: I am following a recipe for braised ribs that calls for wrapping the ribs in heavy duty aluminum foil. I don't have heavy duty, so can regular aluminum foil be used as a replacement?

- I'd at least double it, if not triple it in thickness for cooking ribs. Single ply regular aluminum foil won't give you the result you're looking for.

- Q: Is aluminum sheet resistant to UV rays?

- Yes, aluminum sheet is resistant to UV rays. Aluminum naturally forms a protective oxide layer that acts as a barrier against UV radiation. This oxide layer helps to prevent the aluminum sheet from being damaged or degraded by exposure to the sun's UV rays. This makes aluminum sheet a suitable material for outdoor applications, where it can withstand prolonged exposure to sunlight without fading or deteriorating. Additionally, the reflective properties of aluminum further contribute to its UV resistance, as it can reflect a significant amount of the sun's rays, reducing heat absorption and potential damage.

- Q: This question asks about the various types of adhesives that can be used to bond aluminum sheets together.

- <p>There are several types of adhesives suitable for bonding aluminum sheets together, including epoxy adhesives, which offer strong bonding and resistance to heat and chemicals; acrylic adhesives, known for their flexibility and resistance to UV light; cyanoacrylate adhesives, or super glues, which provide fast bonding but may not be as strong for heavy-duty applications; polyurethane adhesives, which are durable and flexible; and silicone adhesives, which are excellent for high-temperature applications and provide water resistance. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, temperature resistance, and curing time.</p>

Send your message to us

Brushed Aluminum Sheets Canada - PVDF Color Coating Aluminium Sheet for Sandwich Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords