PVDF Color Coated Aluminium Sheet for Building Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of PVDF Color Coated Aluminium Sheet for Building Curtain Walls

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | 0.03MM-3.0MM |

WIDTH | 30mm-1700mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE ,PVDF , EPOXY,16-25MICRON PAINTING THICK, MAX 40MICRONS |

STANDARD | GB/T 17748-1999 |

2. Application of PVDF Color Coated Aluminium Sheet for Building Curtain Walls

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of PVDF Color Coated Aluminium Sheet for Building Curtain Walls

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

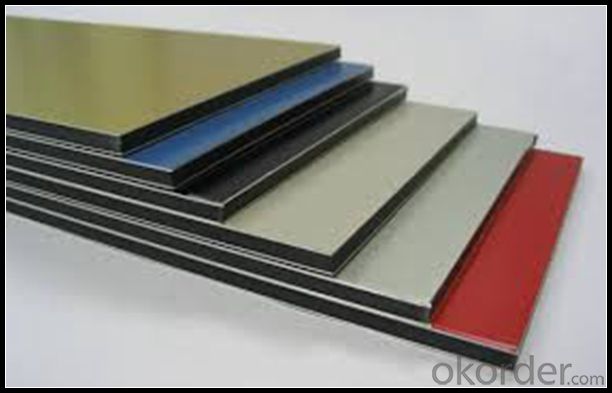

5. Image of PVDF Color Coated Aluminium Sheet for Building Curtain Walls

6. Package and shipping of PVDF Color Coated Aluminium Sheet for Building Curtain Walls

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are the aluminum sheets suitable for manufacturing automotive fuel tanks?

- Yes, aluminum sheets are suitable for manufacturing automotive fuel tanks. Aluminum is a preferred material for fuel tanks due to its excellent properties such as lightweight, durability, corrosion resistance, and high strength-to-weight ratio. These properties make aluminum sheets highly suitable for manufacturing automotive fuel tanks as they provide fuel efficiency, reduce vehicle weight, and enhance overall performance. Moreover, aluminum can be easily formed and welded, allowing automotive manufacturers to create complex tank designs while maintaining structural integrity. Additionally, aluminum sheets have a low melting point, which facilitates the welding process during tank manufacturing. Overall, the use of aluminum sheets in the production of automotive fuel tanks is a reliable choice that meets safety standards and contributes to the efficiency and performance of vehicles.

- Q: What is the lifespan of an aluminum sheet?

- The lifespan of an aluminum sheet can vary depending on various factors such as the thickness of the sheet, the quality of the aluminum, and the conditions it is exposed to. However, under normal circumstances, aluminum sheets can last for several decades or even longer if properly maintained and protected from corrosion.

- Q: Can 101 aluminum sheets be powder coated?

- Yes, 101 aluminum sheets can be powder coated.

- Q: Are aluminum sheets fire resistant?

- In reality, fire resistance characterizes aluminum sheets. With a high melting point and difficulty in igniting or burning, aluminum emerges as a non-combustible substance that hinders fire propagation. Consequently, aluminum sheets find extensive utilization in sectors like construction and aerospace, where fire resistance assumes paramount importance. Nevertheless, it is crucial to acknowledge that although aluminum inherently possesses fire resistance, the materials or substances affixed to or in contact with the aluminum sheet might lack such properties.

- Q: What are the different methods of surface engraving aluminum sheets?

- There are several methods of surface engraving aluminum sheets, including laser engraving, mechanical engraving, chemical etching, and diamond drag engraving. Each method offers different levels of precision and depth, allowing for various artistic or functional purposes.

- Q: 6061-T6 can aluminum sheets be bent?

- You ask if the two batch of aluminum material has been aging, the hardness of the aluminum after aging is higher than before the aging. Another aluminum material from the extrusion after the storage time and environment also related. You can measure the hardness of the two batch of aluminum.

- Q: This question asks for the various dimensions in which aluminum sheets can be obtained.

- <p>Aluminum sheets are available in a variety of sizes depending on the manufacturer and the specific application. Common sizes include 12x12 inches, 24x24 inches, 4x8 feet, and 4x10 feet. Thickness can range from 0.010 inches (0.25 mm) for thin sheets to 0.5 inches (12.7 mm) for thicker plates. Custom sizes can also be ordered, and the availability of these sizes may vary by supplier. It's important to check with the specific supplier for the exact sizes they offer, as options can differ.</p>

- Q: What are the standard sizes and availability of aluminum sheets in the market?

- The standard sizes and availability of aluminum sheets in the market can vary depending on the location and specific requirements. However, there are some commonly available sizes that can generally be found in most markets. In terms of thickness, aluminum sheets are commonly available in 0.02 to 0.2 inches (0.5 to 5 millimeters) thickness range. Thinner sheets (0.02 to 0.06 inches) are often used for lightweight applications such as signage or crafts, while thicker sheets (0.1 to 0.2 inches) are typically used for more heavy-duty applications like construction or industrial purposes. Regarding width and length, standard aluminum sheet sizes are often offered in 4 feet by 8 feet (48 inches by 96 inches) or 4 feet by 12 feet (48 inches by 144 inches). These dimensions are widely available and suitable for various applications. However, it's important to note that custom sizes can also be ordered or cut from larger sheets to meet specific project requirements. Availability of aluminum sheets can be found in various locations, including local hardware stores, metal suppliers, and online marketplaces. It is always recommended to check with local suppliers or conduct online research to determine the specific sizes and availability in your area. Additionally, different grades or alloys of aluminum may have varying availability, so it's essential to consider the specific requirements of your project when sourcing aluminum sheets.

- Q: when aluminum metal undergoes a combination reaction with O2(g)

- Aluminium metal combines with the oxygen from the air on heating to form aluminium oxide. The reaction can be represented using a balanced equation as 4 Al (s) + 3O2(g) = 2Al2O3(s)

- Q: Its been bugging me for years and i want to know why they say aluminum and not aluminium like it is spelt in the Oxford English dictionary and more importantly the universal periodic table, accepted by all countries, does anyone know why? I would like all opinions on this matter, if possible, thank you

- Aluminum okorder /... It’s clear that the shift in the USA from –ium to –um took place progressively over a period starting in about 1895, when the metal began to be widely available ... The American Chemical Society only adopted it in 1925, though this was clearly in response to the popular shift that had already taken place.

Send your message to us

PVDF Color Coated Aluminium Sheet for Building Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords