PVC insulating compound for UL standard wires and cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC insulating compound for UL standard wires and cables

I. Type andapplication

Type | Product | Application and Cable Specification |

5601N | PVC insulating compound for UL standard at 60℃ | Used for wires and cables which according with UL standard, such as UL62, 83, 758, 1581 and etc |

5801N | No lead PVC insulating compound for UL standard at 80℃ | Used for wires and cables which according with UL standard, such as UL62, 83, 758, 1581 and etc |

5901N | No lead PVC insulating compound for UL standard at 90℃ | Used for wires and cables which according with UL standard, such as UL62, 83, 758, 1581 and etc |

5501N | No lead PVC insulating compound for UL standard at 105℃ | Used for wires and cables which according with UL standard, such as UL62, 83, 758, 1581 and etc |

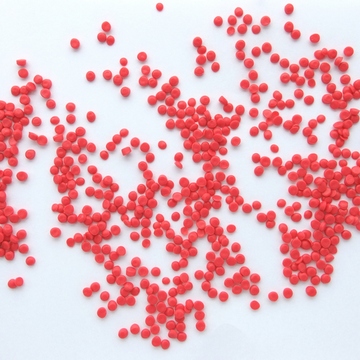

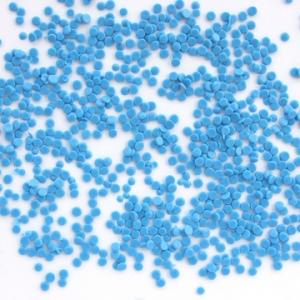

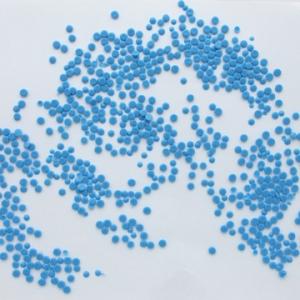

II. Productdescription

PVC insulatingcompound for UL standard wires and cables, based on PVC resin, is made intogranula by mixing, plastification and granulation with adding plasticizer,stabilizing agent, flame retardant and etc. The products meet various specialrequirements, such as different hardness, UV stable, environment friend (RoHs,REACH, PAHs, chlorinated alkanes free, phthalate free, and etc.), sub-shine and fog surface, low temperatureresistant, PS/ABS transfer proof, rodent-repellent, termite-repellent, andtransparent, and etc.

III. Processing

It is recommended that compound should beprocessed with common extruder having a minimum L/D ratio of 20.

The following temperature(℃)profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 160 | 170 | 175 | 180 | 175 |

IV. Storageand transport

Packaging:25kg/bag, PE membrane inside bag and Kraft outsidebag.

Storage and transport: Avoiding in directsunlight and weathering. The storage place should be in clean, cool, dry, andventilated conditions.

V. Properties

Table

Item | Unit | Standard Value | |||

5601N | 5801N | 5901N | 5501N | ||

Tensile Strength | ≥MPa | 15.0 | 15.0 | 15.0 | 15.0 |

Elongation at Break | ≥ % | 150 | 150 | 150 | 150 |

Impact Brittleness Temperature | ℃ | -15 | -15 | -15 | -15 |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 1.0×1011 | 1.0×1011 | 1.0×1011 | 1.0×1011 |

Volume Resistance at working temperature | ≥Ω﹒m | 1.0×108 | 1.0×108 | 1.0×108 | 1.0×108 |

Dielectric Strength | ≥MV/m | 20 | 20 | 20 | 20 |

Hot Deformation | ≤ % | 40 | 40 | 30 | 30 |

Thermal Stability Time at 200℃ | ≥min | 60 | 80 | 100 | 120 |

Thermal Aging (UL oven) |

|

|

|

|

|

Aging Temperature | ℃ | 100±1 | 100±1 (113±1) | 121±1 | 136±1 |

Aging Time | h | 168 | 240 (168) | 168 | 168 |

Retention on Tensile Strength | ≥ % | +85 | +85 | +85 | +85 |

Variation on Elongation at Break | ≥ % | +65 | +65 | +65 | +65 |

- Q: Do olive nets affect the pollination process?

- No, olive nets do not affect the pollination process as they are specifically designed to protect the olives from pests without obstructing the access of pollinators such as bees and other insects to the flowers.

- Q: How do you glue a broken plastic basin?

- Find you a soft plastic, burn it, drop the drop of plastic in the dew place!!

- Q: Can olive nets be used for both green and black olives?

- Yes, olive nets can be used for both green and black olives. Olive nets are designed to catch falling olives during harvest, regardless of their color.

- Q: How do you prevent olive nets from getting entangled with the olive harvesting equipment?

- One way to prevent olive nets from getting entangled with the olive harvesting equipment is by properly securing and fastening the nets to the ground. Ensuring that the nets are taut and securely fixed in place can minimize the chances of them getting caught in the machinery. Additionally, using equipment with proper safety features and guards can help prevent entanglement accidents. Regular maintenance and inspections of both the equipment and the nets can also identify any potential issues or risks before they become problematic.

- Q: What's the difference between memory plastic and sheet metal?

- Ingredients: most of the ingredients are acetate fibers, and a few high-grade frames are fibers of propionic acid. The cellulose fiber sheet is divided into injection molding and compression grinding type, injection molding, as the name suggests, is watered by the mold, but most of the current press polishing processing plate glasses. On the origin of the plate, France and Italy plate is better, and Japan is also relatively good, many of the high grade plate glasses are based on these high-quality plates, and therefore more trustworthy quality. Design: designed for the general public and the pursuit of quality of life students tailor-made. Features: simple, introverted design style, the overall show of a sedate side, using the right coloring process. Emphasize stereoscopic changes in the mirror's leg line.

- Q: Can olive nets be used on large-scale olive orchards?

- Yes, olive nets can be used on large-scale olive orchards. Olive nets are commonly used in commercial olive farming to protect the harvested olives from falling on the ground, reducing losses and ensuring higher yields. These nets can be spread over the entire orchard, effectively catching the olives as they are mechanically harvested or shaken from the trees. The use of olive nets on large-scale olive orchards is an efficient method to optimize production and maintain the quality of the harvested olives.

- Q: What glue does the plastic product stick with?

- 502 glue for porous absorbent material and then, for iron and steel, nonferrous metals, rubber, leather, plastics, ceramics, wood, non-ferrous metals, non metals ceramics, glass and flexible materials such as rubber, leather, soft and hard plastic or their mutual adhesion, but of polyethylene, polypropylene, Teflon ethylene and other hard bonding materials, the surface through special treatment, in order to bond. Widely used in electrical appliances, meters, machinery, electronics, light instruments, medical, light industry, civil and so on.

- Q: Are there any specific techniques for removing olive nets after harvesting?

- Yes, there are specific techniques for removing olive nets after harvesting. One common method is to gently lift the nets from the ground, ensuring that the olives are not damaged or scattered. Careful removal of the nets helps prevent any potential harm to the trees or fruit. Additionally, it is essential to clean and store the nets properly for future use.

- Q: Are there any specific safety precautions to be followed while using olive nets?

- Yes, there are specific safety precautions to be followed while using olive nets. It is important to wear appropriate personal protective equipment such as gloves and goggles to protect against any potential injuries. Additionally, ensuring a stable and secure setup of the nets is crucial to prevent accidents or falls. Regular inspection and maintenance of the nets is also necessary to identify any damages or weak spots that could pose a safety risk.

- Q: Do olive nets require any specific labeling or certification?

- Yes, olive nets may require specific labeling or certification depending on the country or region where they are being used. Some countries have regulations in place to ensure the safety and quality of agricultural products, including olive nets. Labeling and certification may be required to indicate the type of material used, the manufacturer's information, and compliance with specific standards or guidelines. It is advisable to check with local authorities or regulatory bodies to determine the specific labeling or certification requirements for olive nets in a particular area.

Send your message to us

PVC insulating compound for UL standard wires and cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords