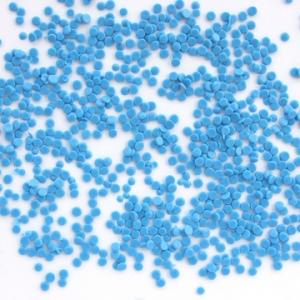

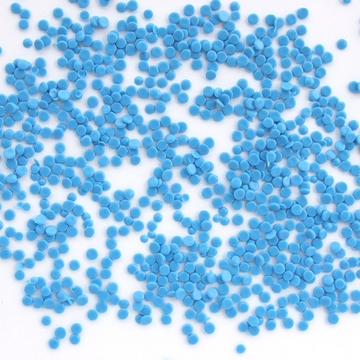

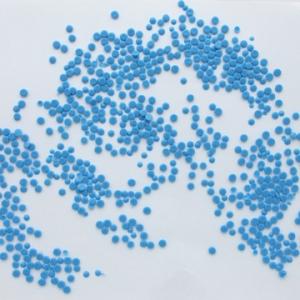

PVC insulating compound for automotive wires

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC insulating compound for automotive wires

I. Type andapplication

Type | Product | Application and Cable Specification |

4701N | 70℃PVC insulating compound for automotive wires | Insulating compound for automotive wires which operation temperature of conductor is 70℃ |

4901N | 90℃PVC insulating compound for automotive wires | Insulating compound for automotive wires which operation temperature of conductor is 90℃ |

4051N | 105℃PVC insulating compound for thin wall automotive wires | Insulating compound for thin wall automotive wires which conductor section is less than 0.5 mm2, according with DIN72551 and JASO D611 standard |

4052N | 105℃PVC insulating compound for thin wall automotive wires | Insulating compound for thin wall automotive wires which conductor section is more than 0.5 mm2, according with DIN72551 and JASO D611 standard |

II. Productdescription

PVC insulatingcompound for automotive wires, based on PVC resin, is made into granula bymixing, plastification and granulation with adding plasticizer, stabilizingagent, flame retardant and etc. The products meet various specialrequirements, environment friend (RoHs, REACH, PAHs, chlorinated alkanesfree, phthalate free, and etc.), andetc.

III. Processing

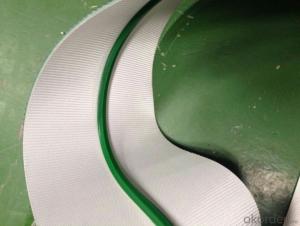

It is recommended that compound should beprocessed with common extruder having a minimum L/D ratio of 20.

The following temperature(℃) profileof extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 150 | 165 | 175 | 180 | 180 | 175 |

IV. Storageand transport

Packaging:25kg/bag, PEmembrane inside bag and Kraft outside bag.

Storage and transport: Avoiding in directsunlight and weathering. The storage place should be in clean, cool, dry, andventilated conditions.

V. Properties

Item | Unit | Standard Value | ||||

4701N | 4901N | 4051N | 4052N | |||

Tensile Strength | ≥ MPa | 16.0 | 16.0 | 16.0 | 16.0 | |

Elongation at Break | ≥ % | 150 | 150 | 150 | 150 | |

Impact Brittleness Temperature | ℃ | -15 | -15 | -15 | -15 | |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 1.0×1011 | 1.0×1011 | 1.0×1011 | 1.0×1011 | |

Volume Resistance at working temperature | Temperature | ℃ | 70±1 | 90±1 | 95±1 | 95±1 |

Volume Resistance | ≥Ω﹒m | 1.0×108 | 1.0×108 | 1.0×108 | 1.0×108 | |

Dielectric Strength | ≥ MV/m | 20 | 20 | 25 | 25 | |

Hot Deformation | ≤ % | 40 | 40 | 30 | 30 | |

Thermal Stability Time at 200℃ | ≥ min | 60 | 60 | 100 | 100 | |

Thermal Aging |

|

|

|

|

| |

Aging Temperature | ℃ | 100±2 | 120±2 | 135±2 | 135±2 | |

Aging Time | h | 168 | 120 | 168 | 168 | |

Tensile Strength after aging | ≥ MPa | 16.0 | 16.0 | 16.0 | 16.0 | |

Variation on Tensile Strength | % | ±20 | ±20 | ±20 | ±20 | |

Elongation at Break after aging | ≥ % | 150 | 150 | 150 | 150 | |

Variation on Elongation at Break | % | ±20 | ±20 | ±20 | ±20 | |

Hardness | A | 92±2 | 92±2 | 95±2 | 92±2 | |

- Q: Do olive nets protect against hailstorms?

- No, olive nets do not protect against hailstorms.

- Q: White plastic for a long time. Why does it turn yellow?

- The plastic box production after or after using for a long time are yellow because the material used in aging, or perhaps because produced after degradation, the most serious of this phenomenon is that some white plastic box, such as some white box, plastic barrels and so on.

- Q: Can olive nets be used for olive trees in regions with high disease incidence?

- Yes, olive nets can be used for olive trees in regions with high disease incidence. Olive nets act as a physical barrier, protecting the trees from external factors such as pests and diseases. They can help reduce the spread of diseases by preventing the entry of infected insects or pathogens, providing a layer of protection for the olive trees.

- Q: Can olive nets be used to reduce the risk of soil erosion in areas with poor soil conditions?

- Yes, olive nets can be used to reduce the risk of soil erosion in areas with poor soil conditions. Olive nets are typically used in olive orchards to prevent soil erosion by protecting the soil from wind and water erosion. These nets act as a physical barrier, preventing the topsoil from being washed away or blown off by strong winds. Additionally, olive trees themselves help stabilize the soil with their extensive root systems. Therefore, using olive nets in areas with poor soil conditions can effectively mitigate the risk of soil erosion.

- Q: Advantages and disadvantages of plastics

- The plastic can be processed into various shapes according to the requirement of use, and the processing technology is simple, and the machine is suitable for large-scale production by mechanization.

- Q: What are the main raw materials used in plastic products?

- ABS plastic (acrylonitrile butadiene styrene) English Name: AcrylonitrileButadiene StyreneSpecific gravity: 1.05 g / cubic centimeter molding shrinkage: 0.4-0.7% molding temperature: 200-240 DEG C, drying conditions: 80-90 hours, 2 hoursThe material performance is 1, the comprehensive performance is better, the impact strength is higher, the chemical stability and the electrical performance are good. It is suitable for making general mechanical parts, reducing wear and wear parts, transmission parts and telecommunications parts2, and 372 organic glass welding good, made of two color plastic parts, and surface chromium plating, spray paint processing3, high impact, high heat resistance, flame retardant, enhanced, transparent and so on.4, liquidity is a little worse than HIPS, better than PMMA, PC and so on, good flexibility.

- Q: How does an olive net affect the overall water usage in the olive grove?

- An olive net helps reduce overall water usage in an olive grove by preventing evaporation and retaining moisture in the soil.

- Q: How do I clean an olive net?

- To clean an olive net, start by removing any debris and leaves from the net using a broom or a leaf blower. Then, lay the net flat on the ground and hose it down with water to remove dirt and remaining particles. For stubborn stains or sticky residue, mix a mild detergent with water and gently scrub the affected areas using a soft brush. Rinse the net thoroughly with water and allow it to air dry before storing it properly.

- Q: Can olive nets be used to reduce the risk of soil erosion during heavy rains?

- Yes, olive nets can be used to reduce the risk of soil erosion during heavy rains. These nets are designed to prevent the movement of soil particles and rainwater runoff, effectively stabilizing the soil and protecting it from erosion.

- Q: How do I see if the plastic cup is qualified?

- As a result, the identification of plastic varieties has become simple and easy, and the cost of recycling has been substantially reduced. Today, many countries in the world have adopted the SPI logo scheme. China enacted almost identical labeling standards in 1996.

Send your message to us

PVC insulating compound for automotive wires

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords