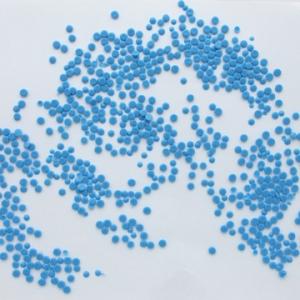

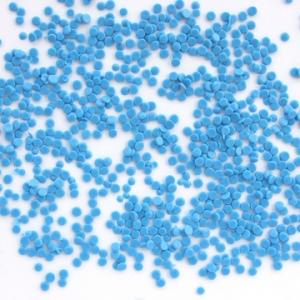

PVC insulating compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

I. Type andapplication

Type | Product | Application and Cable Specification |

7001N | 70℃PVC insulating compound | Used for instrument and communication cables which working voltage less than 0.6/1kV, according with PVC/C standard of GB5023,and J-70 standard of GBT/8815-2008 . |

7002N | 70℃Flexible PVC insulating compound | Used for flexible cables which working voltage less than 450/750V, according with PVC/D standard of GB5023, and JR-70 standard of GBT/8815-2008. |

JGD-70 | 70℃ High electrical properties PVC insulating compound | Used for power cables which working voltage less than 3.6/6kV, according with JGD-70 standard of GBT/8815-2008. |

J-90N | 90℃PVC insulating compound | Used for heat resistant wires and cables which working voltage less than 450/750V, according with PVC/E standard of GB5023, and J-90 standard of GBT/8815-2008. |

PVC insulating compound for wires andcables, based on PVC resin, is made into granula by mixing, plastification andgranulation with adding plasticizer, stabilizing agent, pigment and etc. Theproducts meet various special requirements, such as different hardness, UVstable, environment friend (RoHs, REACH, PAHs, chlorinated alkanes free, phthalate free, and etc.), sub-shine and fogsurface, low temperature resistant, PS/ABS transfer proof, rodent-repellent,termite-repellent, and transparent, and etc.

III.Processing:

Itis recommended that compound should be processed with common extruder having aminimum L/D ratio of 20.

Thefollowing temperature(℃)profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 160 | 170 | 175 | 180 | 175 |

Packaging:25kg/bag,PE membrane inside bag and Kraft outside bag.

Storageand transport: Avoiding in direct sunlight and weathering. The storage place shouldbe in clean, cool, dry, and ventilated conditions.

Ⅴ、Properties

Table

Unit | Standard Value | ||||||

7001N | 7002N | JGD-70 | J-90N | ||||

Tensile Strength | ≥ MPa | 15.0 | 15.0 | 16.0 | 16.0 | ||

Elongation at Break | ≥ % | 150 | 180 | 150 | 150 | ||

Impact Brittleness Temperature | ℃ | -15 | -20 | -15 | -15 | ||

≥Ω﹒m | 1.0×1012 | 1.0×1011 | 3.0×1012 | 1.0×1012 | |||

Volume Resistance at working temperature | Temperature | ℃ | 70±1 | 70±1 | 70±1 | 95±1 | |

Volume Resistance | ≥Ω﹒m | 1.0×109 | 1.0×108 | 5.0×109 | 5.0×108 | ||

Dielectric Strength | ≥ MV/m | 20 | 20 | 25 | 20 | ||

Hot Deformation | ≤ % | 40 | 50 | 30 | 30 | ||

Thermal Stability Time at 200℃ | ≥ min | 60 | 60 | 100 | 180 | ||

Thermal Aging |

|

|

|

|

|

| |

Aging Temperature | ℃ | 100±2 | 100±2 | 100±2 | 135±2 | 115±2 | |

Aging Time | h | 168 | 168 | 168 | 240 | 240 | |

Tensile Strength after aging | ≥ MPa | 15.0 | 15.0 | 16.0 | 16.0 | - | |

Variation on Tensile Strength | % | ±20 | ±20 | ±20 | ±20 | - | |

Elongation at Break after aging | ≥ % | 150 | 180 | 150 | 150 | - | |

Variation on Elongation at Break | % | ±20 | ±20 | ±20 | ±20 | - | |

Loss of Mass | ≤ g/m2 | 20 | 20 | 20 | - | 20 | |

Dielectric Loss Factor | ≤ | - | - | 0.1 | - | - | |

- Q: Can olive nets be used for other crops besides olives?

- Yes, olive nets can be used for other crops besides olives. Olive nets can be used to protect various fruit crops, such as cherries, citrus fruits, and other small fruits from birds and other pests. Additionally, they can also be used for supporting and protecting vineyards and other climbing plants.

- Q: What are the advantages and disadvantages of plastic packaging materials?

- Disadvantages of plastic packaging materials:For single individual resin especially monomer polyethylene, when they are selected for production of plastic packaging materials, if the content is too high, that is to reach a certain concentration, it is easy to be absorbed by the packaging of food, so as to produce certain harm to human body, therefore, for some plastic packaging materials they are not, widely used in food packaging. In addition, plastic packaging, as well as strength, hardness is not as good as metal, high material, poor heat resistance, material aging and other characteristics, these are unavoidable shortcomings of plastic packaging materials.Said so much, I believe that the advantages of plastic packaging materials have a basic understanding, here Xiaobian plastic Kushi recommends that in future food packaging, if there is a high demand for fresh, or try to avoid the plastic package!

- Q: Can olive nets be used for olive tree pollination purposes?

- No, olive nets are not used for olive tree pollination purposes. Olive trees are pollinated by wind or insects, such as bees, and do not require nets for this process. Nets are typically used in olive groves to protect the ripening olives from birds or other pests.

- Q: Can olive nets be used in combination with rootstock selection methods?

- Yes, olive nets can be used in combination with rootstock selection methods. Olive nets are primarily used to protect the olive trees and their fruits from pests, birds, and adverse weather conditions. Rootstock selection methods, on the other hand, involve choosing the appropriate rootstock for olive trees based on their resistance to diseases, growth characteristics, and environmental conditions. Both these techniques serve different purposes but can be used simultaneously to ensure optimal growth and protection of olive trees.

- Q: Are olive nets compatible with irrigation systems?

- Yes, olive nets are compatible with irrigation systems. Olive nets are designed to protect olive trees from birds and other pests, while irrigation systems are used to provide water to the trees. The nets can be installed in a way that allows water from the irrigation system to reach the trees effectively, ensuring proper hydration while also providing protection.

- Q: Can olive nets be used to improve fruit quality?

- Yes, olive nets can be used to improve fruit quality. Olive nets help protect the fruit from damage caused by insects, pests, and birds. They also provide shade, which can prevent sunburn and maintain a more optimal temperature for fruit development. Additionally, olive nets reduce the risk of contamination from dust and debris, resulting in cleaner and higher quality fruit.

- Q: How do you prevent olive nets from causing damage to wildlife or birds?

- To prevent olive nets from causing damage to wildlife or birds, several measures can be taken. Firstly, using nets with smaller mesh sizes can help to prevent birds from becoming entangled or trapped in the netting. Secondly, employing scare tactics like visual deterrents such as reflective tape or flags can deter birds from approaching the nets. Additionally, implementing proper net installation techniques, such as ensuring the nets are properly secured and taut, can minimize the risk of birds getting caught. Regular monitoring of the nets and immediate removal of any trapped wildlife or birds is crucial to prevent harm. Finally, considering alternative methods like using bird-friendly nets or mechanical harvesting can further reduce the potential impact on wildlife and birds during olive harvesting.

- Q: Can olive nets be used in combination with other harvesting tools?

- Yes, olive nets can be used in combination with other harvesting tools such as hand rakes, mechanical harvesters, or vibrating machines. The nets are typically spread underneath the olive trees to catch the falling olives, while the other tools are used to facilitate the harvesting process. This combination of tools can enhance efficiency and ensure a more effective olive harvest.

- Q: How do olive nets affect the yield of an olive grove?

- Olive nets significantly affect the yield of an olive grove by providing protection against birds, reducing fruit loss due to predation. The nets act as a barrier, preventing birds from accessing the olives, which helps to preserve a higher percentage of the crop. Additionally, olive nets also aid in controlling sunburn damage on the fruits, resulting in a higher quality yield. Overall, the use of olive nets positively impacts the yield and productivity of an olive grove.

- Q: What is the role of calcium carbonate in plastics?

- Improve the hardness and rigidity of plastic productsIn plastics, especially in soft PVC, the hardness increases with the amount of calcium carbonate, and the elongation decreases with the increase of hardness. Particle size, oil absorption value of calcium carbonate, hardness growth rate. Conversely, the particle crude oil absorption value of small calcium carbonate, plastic hardness growth rate is small. In soft PVC, calcium carbonate (light) is the next to the lowest hardness growth rate of heavy calcium carbonate.

Send your message to us

PVC insulating compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords