PVC compound for AS standard wires and cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

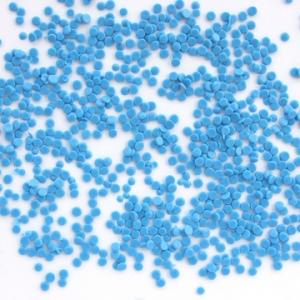

PVC compound for AS standard wires and cables

I. Type andapplication

Type | Product | Application and Cable Specification |

V-90 | 90℃ PVC insulating compound | According with V-90、standard of AS/NZS 3808:2004 |

5V-90 | 90℃ PVC jacket compound | According with 5V-90 standard of AS/NZS 3808:2004 |

II. Product description

PVC compound for AS standard wires andcables, based on PVC resin, is made into granula by mixing, plastification andgranulation with adding plasticizer, stabilizing agent, flame retardant andetc. The products meet various special requirements, such as differenthardness, UV stable, environment friend (RoHs, REACH, PAHs, chlorinated alkanesfree, phthalate free, and etc.),sub-shine and fog surface, low temperature resistant, PS/ABS transfer proof,rodent-repellent, termite-repellent, and transparent, and etc.

III. Processing

It is recommended that compound should beprocessed with common extruder having a minimum L/D ratio of 20.

The following temperature(℃) profile of extruder is recommended

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 165 | 170 | 175 | 175 | 175 |

IV. Storage and transport

Packaging:25kg/bag, PE membrane inside bag and Kraft outsidebag.

Storage and transport: Avoiding in directsunlight and weathering. The storage place should be in clean, cool, dry, andventilated conditions.

V. Properties

Table

Item | Unit | Standard Value | |

V-90 | 5V-90 | ||

Tensile Strength | ≥ MPa | 12.5 | 12.5 |

Elongation at Break | ≥ % | 150 | 150 |

Impact Brittleness Temperature | ℃ | -15 | - |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 4.0×1010 | - |

Volume Resistivity, at 90℃ | ≥Ω﹒m | 2.0×106 | - |

Dielectric Strength | ≥ MV/m | 20 | 18 |

Hot Deformation | ≤ % | 50 | 50 |

Thermal Stability Time at 200℃ | ≥ min | - | - |

Thermal Aging |

|

|

|

Aging Temperature | ℃ | 115±2 | 115±2 |

Aging Time | h | 504 | 504 |

Tensile Strength after aging | ≥ MPa | - | - |

Retention on Tensile Strength | % | +75 | +75 |

Elongation at Break after aging | ≥ % | - | - |

Retention on Elongation at Break | % | +65 | +65 |

Loss of Mass | ≤ mg/cm2 | 2.5 | 2.5 |

- Q: What are the hazards of plastic oiler

- Phthalates, two formic acid and phenol methane, are common chemicals used in plastic products. They have carcinogenic effects on humans over a long period of time. So use plastic less food.

- Q: Can olive nets be used to improve fruit set?

- Yes, olive nets can be used to improve fruit set. Olive nets are commonly used in olive groves to protect the olive trees and fruits from birds, insects, and other potential damages. By covering the trees with olive nets during the flowering period, the pollination process can be enhanced as it prevents pollen loss due to wind or bird interference. This leads to better fruit set and ultimately increases the yield and quality of olives.

- Q: Can olive nets be rented?

- Yes, olive nets can be rented. Many agricultural equipment rental companies offer olive nets for rent, allowing farmers and individuals to use them for olive harvesting purposes without the need to purchase the nets themselves.

- Q: How long does an olive net last?

- The lifespan of an olive net can vary depending on various factors such as the quality of the net, the environment it is exposed to, and the frequency of use. However, on average, a well-maintained olive net can last anywhere from 5 to 10 years.

- Q: PC plastic can be welded with any plastic electrode

- General PC plastic, our pipe is the use of PC dedicated glue bonding

- Q: How do olive nets prevent damage from frost?

- Olive nets prevent damage from frost by providing a protective barrier over the olive trees, reducing the exposure to cold temperatures and frost. The nets help to trap heat and create a microclimate within the tree canopy, keeping the temperature slightly higher and preventing frost from settling on the trees. This protection helps to minimize frost damage to the olive trees and ensures a better yield during colder periods.

- Q: Standard for classification of fire protection in plastic products

- 2, V-2: the sample was subjected to two 10 second combustion tests, and the flame died within 60 seconds. A fire can fall off. 3, V-1: the sample was subjected to two 10 second combustion tests, and the flame died within 60 seconds. No fire can fall. 4, V-0: the sample was subjected to two 10 second combustion tests, and the flame died within 30 seconds. No fire can fall.

- Q: Are olive nets easy to maintain?

- Yes, olive nets are generally easy to maintain. They require regular cleaning to remove any debris or fallen olives, and occasional repairs or replacement of damaged sections. Overall, with proper care and attention, olive nets can be easily maintained.

- Q: What products are plastic extrusion?

- In addition to granulation, are hollow plastic products are extrusion molding

- Q: What does plastic melt mean?

- Refers to the plastic melt index, now according to the national standard requirements, known as plastic melt flow rate, unit is: grams /10 minutes.

Send your message to us

PVC compound for AS standard wires and cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords