PVC jacket compound for UL stardard wires and cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

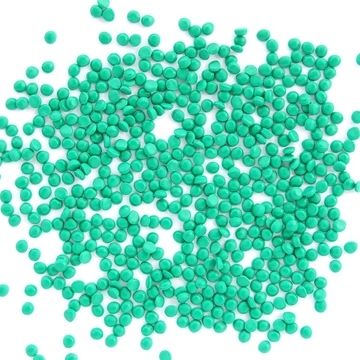

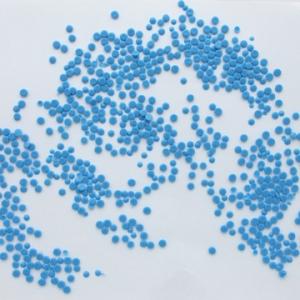

PVC jacket compound for ULstandard wires and cables

I. Type andapplication

Type | Product | Application and Cable Specification |

5621N | PVC jacket compound for UL standard at 60℃ | Used for wires and cables which according with UL standard, such as UL62, 83, 758, 1581 and etc. |

5821N | PVC jacket compound for UL standard at 80℃ | Used for wires and cables which according with UL standard, such as UL62, 83, 758, 1581 and etc. |

5921N | PVC jacket compound for UL standard at 90℃ | Used for wires and cables which according with UL standard, such as UL62, 83, 758, 1581 and etc. |

5521N | PVC jacket compound for UL standard at 105℃ | Used for wires and cables which according with UL standard, such as UL62, 83, 758, 1581 and etc. |

II. Product description

PVC jacket compound for UL standard wires and cables, based on PVCresin, is made into granula by mixing, plastification and granulation withadding plasticizer, stabilizing agent, flame retardant and etc. The productsmeet various special requirements, such as different hardness, UV stable,environment friend (RoHs, REACH, PAHs, chlorinated alkanes free, phthalate free, and etc.), sub-shine and fogsurface, low temperature resistant, PS/ABS transfer proof, rodent-repellent,termite-repellent, and transparent, and etc.

III. Processing:

It is recommended that compound should be processed with commonextruder having a minimum L/D ratio of 20.

The following temperature(℃) profileof extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 160 | 170 | 175 | 175 | 175 |

IV. Storageand transport

Packaging:25kg/bag, PE membrane inside bag and Kraft outsidebag.

Storage and transport: Avoiding in direct sunlight and weathering.The storage place should be in clean, cool, dry, and ventilated conditions.

V. Properties

Table

Item | Unit | Standard Value | |||

5621N | 5821N | 5921N | 5521N | ||

Tensile Strength | ≥ MPa | 15.0 | 15.0 | 15.0 | 15.0 |

Elongation at Break | ≥ % | 150 | 150 | 150 | 150 |

Impact Brittleness Temperature | ℃ | -20 | -20 | -20 | -20 |

Volume Resistivity, at 20℃ | ≥ Ω﹒m | 1.0×109 | 1.0×109 | 1.0×109 | 1.0×109 |

Dielectric Strength | ≥ MV/m | 18 | 18 | 18 | 18 |

Hot Deformation | ≤ % | 50 | 50 | 50 | 50 |

Thermal Stability Time at 200℃ | ≥ min | 60 | 80 | 100 | 120 |

Thermal Aging (UL oven) |

|

|

|

|

|

Aging Temperature | ℃ | 100±1 | 100±1 | 121±1 | 136±1 |

Aging Time | h | 168 | 240 | 168 | 168 |

Retention on Tensile Strength | ≥ % | +85 | +70 | +85 | +85 |

Variation on Elongation at Break | ≥ % | +65 | +65 | +65 | +65 |

- Q: How do olive nets help in reducing the use of chemical pesticides?

- Olive nets help in reducing the use of chemical pesticides by acting as a physical barrier that prevents pests, such as insects or birds, from reaching the olive trees. By keeping pests away, olive nets minimize the need for chemical pesticides to control infestations or deter birds from feeding on the olives. This allows olive growers to adopt more environmentally friendly and sustainable practices in their farming methods.

- Q: Can olive nets be used in combination with cover cropping methods?

- Yes, olive nets can be used in combination with cover cropping methods. Cover cropping involves growing a variety of plants to protect and enrich the soil, while olive nets are used to catch falling olives during harvest. By implementing cover crops in between olive tree rows, the nets can still be used effectively without interfering with the growth and benefits of cover crops. This combined approach can enhance soil health, prevent erosion, and improve overall olive tree productivity.

- Q: Are olive nets easy to clean and maintain?

- Yes, olive nets are generally easy to clean and maintain. They can be shaken or hosed off to remove dirt and debris, and any stubborn stains can be treated with mild soap and water. Additionally, regular maintenance such as checking for tears or damage and storing them properly when not in use can prolong their lifespan.

- Q: Can olive nets be used to reduce soil erosion?

- Yes, olive nets can be used to reduce soil erosion. These nets are typically placed on slopes or areas prone to erosion to prevent soil from being washed away by heavy rainfall or wind. The nets help to stabilize the soil and retain moisture, thereby reducing erosion and promoting healthy plant growth.

- Q: How do olive nets affect the development of olive tree trunks?

- Olive nets do not directly affect the development of olive tree trunks. However, they play a crucial role in protecting the olives from being eaten by birds or other animals, ensuring a successful harvest. By covering the trees with nets, the fruits remain intact, allowing the tree to allocate its resources towards the growth and development of the trunk and branches.

- Q: How do olive nets help in harvesting olives?

- Olive nets are used during olive harvesting to collect the fallen fruits, preventing them from getting damaged or lost. These nets are spread out underneath the olive trees, allowing the olives to drop onto the net rather than falling onto the ground. This makes it easier to gather the olives and ensures a higher yield, as the fruits are kept clean and intact.

- Q: Thinner can clean plastic products?

- If it is a small number of mobile phone plastic shell, you can use eraser to clean; batch can use professional plastic cleaning agent, etc..

- Q: What materials are olive nets typically made of?

- Olive nets are typically made of high-density polyethylene (HDPE) or nylon materials.

- Q: The working principle of plastic mould

- The structure is usually composed of molding parts, gating system, guiding parts, pushing out mechanism, temperature regulating system, exhaust system and supporting parts.

- Q: Is PC the same as plastic?

- PC should be a kind of plastic, PC, its strength can meet the needs from mobile phones to bullet proof glass, the disadvantage is that compared with metal, lack of hardness

Send your message to us

PVC jacket compound for UL stardard wires and cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords