Geocells Ofisis Nomeri High Strength Polyester Geogrid with PVC Coated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

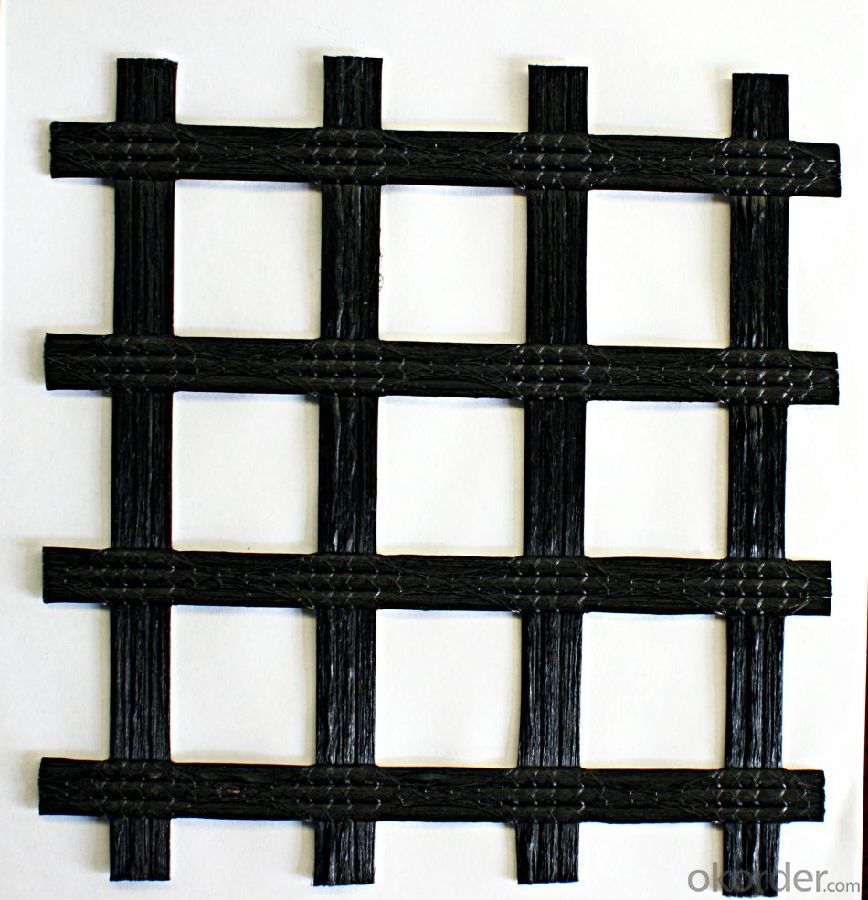

Introduction of Polyester Geogrid:

Polyester geogrid is a new kind of favorable earthwork base material to strength the road surface and roadbed, which composed of high strength polyester yarns coated with an inorganic sizing agent.

Polyester Geogrid known as PET Grid is woven by high strength polymer yarns as per desired mesh sizes and strength from 20kN/m to 800kN/m(Biaxial type), 40-25kN/m to 600-400kN/m(Uniaxial type). Woven PET Grid is created through interlacing, usually at right angles, two or more yarns or filaments. Exterior of PET Grid is coated with polymer or nontoxic substance material for UV, acid and alkali resistance and prevents the bio-decomposition.

PET Grid is widely introduced to the various fields of civil engineering, transportation engineering, and environment issues. The reinforced steep slopes, reinforced retaining earth walls, reinforced embankments, reinforced abutments and piers are typical applications where geogrids are used. The resulting grid structure possesses large openings that enhance interaction with filling material.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What are the criteria for the use of plastic geogrid

- Warp knitted grating, steel plastic grille, plastic grille, fiberglass grille

- Q: What are the potential drawbacks of using geogrids?

- Some potential drawbacks of using geogrids include their high cost compared to other soil stabilization methods, the need for proper installation and maintenance to ensure effectiveness, and limitations in their ability to withstand certain extreme environmental conditions such as high temperatures or chemical exposure. Additionally, geogrids may not be suitable for all soil types or site conditions, requiring a thorough analysis and consideration of alternative solutions.

- Q: Is there a geogrid in the transition section of Railway

- He is mainly a connection and prevent sinking

- Q: Can geogrids be used in retaining walls for waterfront applications?

- Yes, geogrids can be used in retaining walls for waterfront applications. Geogrids are commonly used as reinforcement materials in retaining walls to enhance stability and prevent soil erosion. In waterfront applications, where there is constant exposure to water, geogrids can provide additional strength and durability to the retaining wall structure, making it suitable for such specific conditions.

- Q: Geogrid price? Solution!

- Geogrid effect1 used for roadbed reinforcement, so that the granular filler and mesh together locked together to form a stable plane, to prevent the collapse of the filler, and the vertical load can be dispersed, the geographical conditions of poor areas can be used multi-layer reinforcement;2 in the embankment and embankment fill can increase its stability, reduce the area;

- Q: Who knows how much the staggered distance of the lap joint is

- The staggered distance of the lap joint shall not be less than 300 mm. The concrete specification (geotextile laid overlapping: when) using geotextile as filter layer, should be laid in place in the bottom and sides of the trench wall, soil and reserve covering the top required fabric, straighten ride close to the lower layer, all vertical or horizontal joints should be staggered alternately. The lap length shall not be less than 300MM.A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid.

- Q: Can geogrids be used in reinforced earth bridge piers?

- Yes, geogrids can be used in reinforced earth bridge piers. Geogrids are commonly used in reinforced earth structures to provide stability and increase load-bearing capacity. They can be used to reinforce the soil and provide additional support to bridge piers, improving their structural integrity and longevity.

- Q: What is the meaning of the highway geogrid gsl50/hdpe

- 150 refers to the tensile strength is 150KN, it is impossible to two-way tensile plastic geogrid, plastic composite geogrid material is HDPE material,

- Q: How do geogrids improve the stability of shorelines?

- Geogrids improve the stability of shorelines by providing reinforcement and preventing soil erosion. They are typically installed beneath the surface of the shoreline, creating a strong and stable foundation. Geogrids help distribute the load of the soil and wave forces, reducing the risk of slope failure or collapse. Additionally, they enhance the soil's resistance to erosion caused by waves, currents, or wind, ultimately preserving the shoreline's integrity and preventing further degradation.

- Q: Can geogrids be used in mechanically stabilized earth walls?

- Yes, geogrids can be used in mechanically stabilized earth walls. Geogrids are commonly used as reinforcement materials in retaining walls and slopes to enhance stability and prevent soil erosion. They are designed to distribute loads and provide additional strength to the structure, making them suitable for use in mechanically stabilized earth walls.

Send your message to us

Geocells Ofisis Nomeri High Strength Polyester Geogrid with PVC Coated

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords