Protection platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

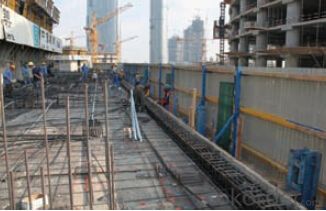

Protection Platform PP-50

A kind of new type construction protection system, applying operating platform and safer job

location for construction corps.

Characteristics:

◆ Easy and quick assembling.

◆ Lifted as a group, it is rapid and economic.

◆ Auto-climbing

◆ A safe and reliable anchor system

1. Composition

2. Assembly process of anchor system

(1) Embed V-climbing cone and anchor plate into the slab.

(2) Fix anchor shoe on the slab by tensile bolt.

(3) The fixed anchor shoe.

◆ High work efficiency with work platform and unload platform

◆ High light transmittance with the hollow block

- Q: Are there any limitations to the size of concrete pours with steel formwork?

- Steel formwork poses limitations for large concrete pours due to various factors. Firstly, the weight and size of the steel formwork itself can be challenging. Maneuvering heavy and large steel formwork can prove difficult, particularly for sizable pours. Moreover, additional supports and bracing are necessary for larger pours. To prevent bending or collapsing under the concrete's weight, steel formwork often requires reinforcement and bracing. This increases the installation's complexity and cost. Additionally, the size and weight of the concrete become limiting factors. Curing large concrete pours generates substantial heat, potentially causing thermal cracking and durability issues. Steel formwork may not endure the intense temperatures and pressures produced by substantial volumes of concrete, leading to deformation or failure. Furthermore, the logistics and transportation of large concrete pours present challenges. Limited availability of concrete trucks and pumps capable of transporting significant volumes can result in delays and escalated expenses. In summary, steel formwork is suitable for diverse concrete pours, but its usage for larger and complex projects necessitates careful evaluation. Assessing project-specific requirements and constraints is crucial to determine the feasibility and appropriateness of employing steel formwork for sizable concrete pours.

- Q: How does steel formwork impact the overall construction cost?

- Steel formwork is widely favored in the construction industry due to its durability, versatility, and reusability, making it a popular choice. When considering the impact that steel formwork has on the overall construction cost, there are several factors that need to be taken into consideration. To begin with, one of the main advantages of steel formwork is its longer lifespan compared to traditional timber formwork. This means that there is less need for frequent replacements, resulting in cost savings. By spreading the initial investment in steel formwork across multiple construction projects, there is no need for continuous purchases of new formwork materials. Furthermore, steel formwork is known for its superior strength and stability. It can withstand higher concrete pressures, allowing for the construction of taller and more complex structures. This maximizes floor space and enhances the overall efficiency of a project, ultimately reducing construction time and costs. In addition, steel formwork provides a smooth and consistent finish to concrete surfaces, which means that there is less need for additional finishing work. This reduces labor costs and the time required for subsequent trades to begin their work, leading to overall cost savings. Moreover, steel formwork is designed to be easily assembled and disassembled, which facilitates faster construction processes. This efficiency translates into reduced labor costs and shorter project durations, ultimately impacting the overall construction cost. However, it is important to note that the initial investment in steel formwork can be higher compared to other formwork materials such as timber or aluminum. Nevertheless, the long-term benefits and potential cost savings associated with steel formwork outweigh this initial expense. In conclusion, steel formwork has a positive impact on the overall construction cost due to its durability, reusability, and efficiency. Its longer lifespan, strength, and ease of use contribute to cost savings through reduced material replacements, shorter project durations, and minimized finishing work. Despite the higher initial investment, the numerous advantages of steel formwork make it a cost-effective choice for construction projects.

- Q: Can steel formwork be used in retail or commercial construction projects?

- Retail or commercial construction projects can benefit greatly from the use of steel formwork. This versatile and durable solution is ideal for creating concrete structures, offering numerous advantages. With its high reusability, excellent dimensional stability, and ability to handle high concrete pressures, steel formwork is a reliable choice. In these types of projects, steel formwork can be utilized for various applications including columns, walls, beams, slabs, and staircases. It provides a strong framework, ensuring accurate and smooth concrete placement, resulting in top-notch finishes. Moreover, steel formwork can be easily customized and adjusted to meet different project requirements, making it suitable for complex architectural designs. In addition to its flexibility, steel formwork also brings significant time and cost savings to construction projects. Its reusability minimizes the need for frequent formwork replacements, leading to reduced material and labor costs. The use of steel formwork further enhances construction efficiency by allowing for quick assembly, disassembly, and repositioning of formwork components. Overall, steel formwork is a dependable and efficient choice for retail or commercial construction projects, providing the necessary strength and flexibility for such applications.

- Q: How does steel formwork contribute to the overall acoustics of the structure?

- The overall acoustics of a structure are not directly affected by steel formwork. Instead, the acoustics of a building primarily depend on the materials used for walls, floors, and ceilings, as well as the design and layout of the space. However, steel formwork can have an indirect impact on acoustics by offering a rigid and stable framework for concrete construction. In the construction industry, steel formwork is commonly utilized to create temporary molds or frameworks for pouring concrete. This formwork system ensures that the concrete takes on the desired shape and structure as it hardens. Although steel formwork itself lacks specific acoustic properties, it aids in establishing a solid and soundproof structure by providing a precise and consistent framework for the concrete. During the construction of a building, it is crucial to minimize any gaps or inconsistencies in the concrete to prevent sound leakage and ensure optimal acoustic performance. The rigidity and strength of steel formwork assist in maintaining the desired shape of the structure, resulting in a more precise and uniform concrete finish. Consequently, this contributes to improved acoustics by reducing the potential for sound transmission through the structure. Furthermore, the use of steel formwork also plays a role in the overall durability and stability of the building, indirectly affecting the acoustics. By providing a sturdy framework, steel formwork helps create a robust structure that is less susceptible to vibrations and structural movement. This stability aids in minimizing the transmission of unwanted noise and vibrations within the building, leading to enhanced acoustic performance. In conclusion, while steel formwork may not directly contribute to the acoustics of a structure, it indirectly influences it by offering a precise and stable framework for pouring concrete. This results in a more uniform and soundproof structure, which reduces sound transmission and improves overall acoustics.

- Q: Production of steel plate for bridge steel plate SPHC and Q235 which material is good? What is the difference?

- Equivalent to GB GB699 (high quality carbon structural steel national standard) in the 10#, 15# steel hot-rolled plate, their carbon content range is about 0.1-0.15%.Q235 is the national standard GB700 (carbon structural steel national standard)

- Q: Can steel formwork be used in areas with high seismic vulnerability?

- Yes, steel formwork can be used in areas with high seismic vulnerability. Steel is a strong and durable material that can withstand the forces and vibrations caused by earthquakes. It provides stability and structural integrity to the formwork system, making it suitable for use in seismic-prone regions. Additionally, steel formwork can be designed and reinforced to meet the specific requirements and regulations of the area, ensuring its suitability for use in high seismic vulnerability zones.

- Q: How does steel formwork prevent concrete segregation?

- Steel formwork helps prevent concrete segregation by providing a rigid and stable structure for the concrete to be poured into. Unlike other types of formwork materials such as wood or plastic, steel formwork maintains its shape and prevents any movement or deformation during the pouring and curing process. Concrete segregation occurs when the different components of concrete, such as cement, aggregates, and water, separate from each other, resulting in an uneven distribution of these components within the mixture. This can weaken the concrete structure and lead to various issues such as reduced strength, cracking, or voids. Steel formwork prevents concrete segregation by offering a smooth and even surface for the concrete to be poured onto. The rigid nature of steel ensures that there are no gaps or spaces for the components of the concrete to separate or settle unevenly. This helps to maintain a consistent and uniform distribution of the cement, aggregates, and water throughout the entire concrete mixture. Additionally, steel formwork provides a tight seal against the sides and bottom of the form, preventing any leakage or loss of moisture during the curing process. This helps in maintaining the required water-cement ratio, which is crucial for the proper hydration and hardening of the concrete. By preventing excessive evaporation or moisture loss, steel formwork ensures that the concrete cures evenly, reducing the chances of segregation. Furthermore, the use of steel formwork allows for precise and accurate placement of the concrete, eliminating any potential gaps or voids that could contribute to segregation. The steel formwork can be designed with various features such as tie rods, clamps, or connectors to hold the formwork panels securely in place, ensuring that the concrete is poured and compacted uniformly. In summary, steel formwork prevents concrete segregation by providing a stable and rigid structure that maintains the shape and integrity of the concrete mixture. It prevents the separation of components, ensures a consistent distribution of materials, and allows for precise and accurate placement of the concrete, resulting in a stronger and more durable structure.

- Q: How does steel formwork affect the overall construction site aesthetics?

- Steel formwork can have a significant impact on the overall aesthetics of a construction site. Unlike traditional timber formwork, steel formwork provides a sleek and modern appearance. Its smooth and clean surfaces give a sense of precision and professionalism to the construction site. The use of steel formwork also allows for more flexibility in design. It can be easily shaped and molded into various intricate shapes, resulting in unique and visually appealing structures. This flexibility enables architects and designers to create innovative and eye-catching architectural elements that enhance the overall aesthetics of the construction site. Furthermore, steel formwork can contribute to the overall cleanliness of the construction site. Its durable and reusable nature reduces the amount of waste generated during construction. This not only helps in maintaining a cleaner and more organized site but also reduces the environmental impact of the construction process. Additionally, steel formwork provides a sense of durability and strength to the construction site. Its robust nature ensures that the structures being built are solid and long-lasting. This adds to the overall impression of quality and stability, enhancing the aesthetics of the construction site. In conclusion, steel formwork positively affects the overall construction site aesthetics by providing a modern and sleek appearance, allowing for flexible and innovative designs, contributing to a cleaner site, and enhancing the sense of durability and strength.

- Q: What are the safety precautions when using steel formwork?

- When using steel formwork, there are several important safety precautions that should be followed to ensure the well-being of workers and the successful completion of the project. 1. Adequate training and awareness: All workers involved in using steel formwork should be properly trained on its safe handling and usage. They should be aware of the potential hazards and the correct procedures to follow. 2. Inspection and maintenance: Before using steel formwork, it is essential to inspect it thoroughly for any defects or damage. Any damaged or weakened parts should be repaired or replaced before use. Regular maintenance should be carried out to ensure the formwork remains in good condition. 3. Proper handling and storage: Steel formwork can be heavy and require multiple workers for handling. It is important to use appropriate lifting and handling equipment, such as cranes or forklifts, to avoid strain or injuries. When storing the formwork, it should be secured properly to prevent it from falling or causing accidents. 4. Fall protection: When working at heights with steel formwork, fall protection measures such as guardrails, safety nets, or personal fall arrest systems should be implemented. Workers should be provided with proper safety harnesses and trained on their usage. 5. Secure installation: Steel formwork should be securely installed to prevent collapse or movement during concrete pouring or other construction activities. It is crucial to follow the manufacturer's instructions and use appropriate bracing and support systems to ensure stability. 6. Adequate signage and barriers: Proper signage and barriers should be placed around the work area to warn others of potential hazards and restrict access to authorized personnel only. This helps in preventing accidents and keeping unauthorized individuals away from the construction site. 7. Personal protective equipment (PPE): All workers involved in using steel formwork should wear appropriate PPE, including hard hats, safety boots, gloves, and eye protection. This protects them from potential injuries caused by falling objects, sharp edges, or other hazards. 8. Regular communication and coordination: Effective communication and coordination among workers using steel formwork are crucial to maintain a safe working environment. Clear instructions, regular safety meetings, and the availability of emergency procedures ensure everyone is aware of their roles and responsibilities. By following these safety precautions, the risks associated with using steel formwork can be minimized, and a safe working environment can be maintained for all workers involved in the construction project.

- Q: Is steel formwork suitable for projects with limited skilled labor?

- Yes, steel formwork is suitable for projects with limited skilled labor. Steel formwork is known for its durability, strength, and ease of use. It requires minimal training and expertise to assemble and disassemble, making it a practical choice for projects where skilled labor is limited. Additionally, steel formwork can be reused multiple times, reducing the need for constant skilled labor and saving costs in the long run.

Send your message to us

Protection platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords