Printing Steel from High Quality and Best Shipping Date

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Description of the Printing Steel:

Printing steel plate is the product based on the metal sheet, of which surface is finally installed of the plastic film (PVC,PE) in addition to being firstly covered with the coating and printed ink in .The coated layer of printing steel plate consists of printing steel plate consists of chemical and filming layer, primer coated layer, pattern printed layer and surface coated layer. The top and back coating shall generally be the application of the weatherproof paint, as well can be the application of the paint with special capabilities such as stain-resistant, self cleaning capability, high thermal resistance, antistatic capability, sterilizing capability, finger-print prevention and etc.

2.Main Features of the the Printing Steel:

• Excellent corrosion resistance

• High temperature oxidation resistance

• High hot reflectance

• Good manufacturability

•Beautiful appearance

•Surface coating

•Cost-effective

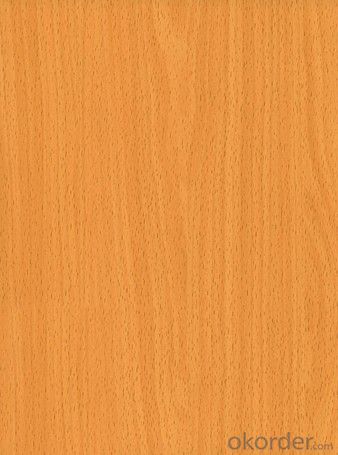

3.Printing Steel Images

4.Printing Steel Specification

Available Specification

PRINTING STEEL | |

BASE MATERIAL | HDGI,ALUZINC,CR |

GRADE | SGCC,DX51D,ASTMA653,EN10142,S350GD |

THICKNESS | 0.20-0.80 mm |

WIDTH | 600-1250 mm |

ZINC COATING | 60-200 g/ m2 |

PAINT | PE,PVDF,SMP,HDP |

COILED | 508mm

|

COIL WEIGHT | 3-6 mt |

5.FAQ of the Printing Steel

We have organized several common questions for our clients,may help you sincerely:

1.What advantages does your company have?

Glass: CNBM owns about 20 modern float glass product`ion lines, With annual capacity of 10 million square meters glass.

Commercial concrete: Annual capacity of 0.35 billion cubic meters, No. 1 in the world.

Refractory Material: Annual capacity of 40,000 tons casting refractory, No.1 in the world.

2. what is your moq

Normally our moq is 25per size ,but it is up to different size

3.how long we will receive the goods ?

After receiving your deposit or workable lc our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

- Q: and which one is better?i'm looking into buying some aftermarket headers, but companies make them in both chrome and stainless steel

- I know nothing of aftermarket headers so can't help you there, but - chrome is a coating on metal. Stainless Steel is a type of metal.

- Q: What is galvanized steel coil?

- Galvanized steel coil refers to a steel sheet that has been coated with a protective layer of zinc to prevent corrosion and increase its durability. This process, known as galvanization, involves immersing the steel coil in a bath of molten zinc, creating a bond that forms a protective barrier against moisture, chemicals, and other elements that can cause rusting. The result is a versatile and long-lasting material commonly used in construction, automotive, and manufacturing industries.

- Q: What are the common coil transportation options?

- The common coil transportation options include trucking, rail transportation, and shipping via barges or vessels.

- Q: What are the different methods of cut-to-length shearing for steel coils?

- There are several different methods of cut-to-length shearing for steel coils, including rotary shearing, flying shear, stationary shear, and programmable logic controller (PLC) controlled shear. Each method has its own advantages and is used based on factors such as coil thickness, desired precision, and production speed requirements.

- Q: How are steel coils used in appliances?

- Steel coils are commonly used in appliances for their strength, durability, and heat conductivity. They are primarily utilized in appliances like refrigerators, air conditioners, and ovens to provide efficient cooling and heating functions. The steel coils act as heat exchangers, transferring thermal energy from one area to another, enabling appliances to control and maintain desired temperatures effectively.

- Q: I'm assuming that brass is flexible, expands and then bounces back to it's original shape. But if aluminum and steel expand and don't contract wouldn't they cause guns to jam more often for example?

- Reloading Aluminum Cases

- Q: i need the same kind of body jewelry they use in the piercing shop but when i go to order them they say stainless steel, not surgical steel, and i have REALLY sensitive skin so i need to be sure, whats the difference?

- This Site Might Help You. RE: is stainless steel and surgical steel the same? i need the same kind of body jewelry they use in the piercing shop but when i go to order them they say stainless steel, not surgical steel, and i have REALLY sensitive skin so i need to be sure, whats the difference?

- Q: I've heard different things bout them, though I do not know this. Oh, and if you know where you can buy some raw or get custom made stuff out of black steel please let me know it would be greatly appreciated. Oh and my friend told me there is a black steel that can be sharpened and silver will be underneath, is this also true? Thank you very much for answering ^^

- black steel and black tron are not same.

- Q: How are steel coils used in the production of roofing panels?

- To manufacture roofing panels, steel coils are indispensable. These coils, usually composed of galvanized or coated steel, serve as the fundamental material for producing robust and top-notch roofing panels. Initially, the steel coils undergo a sequence of operations in a production facility. These operations involve flattening, cleaning, and shaping the coils to achieve the desired dimensions and profiles for the roofing panels. This process guarantees that the steel coils possess uniform thickness and are devoid of any impurities or flaws that could compromise the final product's integrity. Once the steel coils are prepared, they are fed into a roll forming machine. In this machine, the coils are gradually bent and shaped into the specific design and size required for the roofing panels. The roll forming process imparts the panels with their distinct corrugated or standing seam profiles, which enhance their strength and ability to withstand various weather conditions. After the roll forming process, the steel coils are divided into individual roofing panels of the desired length. These panels then undergo further processing to incorporate additional features, such as coatings or finishes, to enhance protection against corrosion and improve aesthetic appeal. Protective layers, such as zinc or paint, are often applied to the steel coils to enhance their resistance to rust, UV rays, and other environmental factors. Lastly, the roofing panels are packaged and transported to construction sites or distributors for installation. The utilization of steel coils in the production of roofing panels ensures that the final product is sturdy, long-lasting, and capable of withstanding heavy loads, strong winds, and other external forces. Steel is renowned for its high tensile strength, making it an ideal material for creating durable roofing panels. In conclusion, steel coils play a vital role in the production of roofing panels. Through a series of manufacturing processes, they are transformed into the desired dimensions and profiles, ensuring consistency and quality. The resulting roofing panels are not only visually pleasing but also highly resilient, providing superior protection and longevity for buildings.

- Q: How do steel coils contribute to the construction equipment industry?

- Steel coils play a crucial role in the construction equipment industry by providing the necessary raw material for manufacturing various construction machinery and equipment. These coils, made from high-quality steel, are used in the fabrication of a wide range of construction equipment, such as cranes, bulldozers, excavators, loaders, and forklifts. The primary contribution of steel coils to the construction equipment industry lies in their structural strength and durability. Steel is known for its excellent mechanical properties, including high tensile strength, toughness, and resistance to wear and corrosion. These qualities make it an ideal material for constructing heavy-duty machinery that can withstand the demanding conditions of construction sites. Steel coils are used to manufacture the structural components of construction equipment, such as chassis, frames, booms, buckets, and attachments. These components need to be robust and able to withstand heavy loads, impacts, and constant use. Steel coils provide the necessary strength and reliability to ensure the longevity and performance of construction equipment. Furthermore, steel coils are also used to fabricate specialized parts and accessories for construction machinery. These include hydraulic systems, gears, shafts, bearings, and fasteners. These components are crucial for the proper functioning and efficiency of construction equipment, and steel coils provide the high-quality material needed to manufacture them. In addition to their mechanical properties, steel coils also contribute to the construction equipment industry through their versatility and customization options. Steel can be easily shaped, cut, welded, and formed into various shapes and sizes, allowing manufacturers to create equipment with specific designs and functionalities to meet the diverse needs of construction projects. Overall, steel coils are indispensable in the construction equipment industry as they provide the foundation for robust and reliable machinery. Their strength, durability, and versatility make them an essential raw material for manufacturing construction equipment that can withstand the rigors of the construction site and ensure the safety and efficiency of construction projects.

Send your message to us

Printing Steel from High Quality and Best Shipping Date

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords