Print Prepainted Galvanized Steel Coil Wooden Pattern For House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Print Prepainted Galvanized Steel Coil Wooden Pattern For House:

With Gi as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Print Prepainted Galvanized Steel Coil Wooden Pattern For House:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

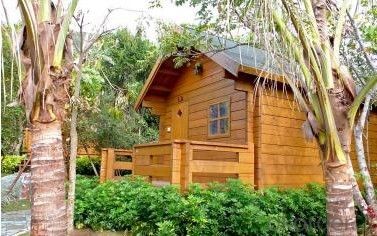

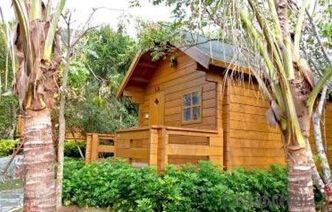

3.Print Prepainted Galvanized Steel Coil Wooden Pattern For House Images

4.Print Prepainted Galvanized Steel Coil Wooden Pattern For House Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Print Prepainted Galvanized Steel Coil Wooden Pattern For House:

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long we will receive the goods?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. What is your moq ?

Normally our moq is 25mt per size ,but it is up to different size.

- Q: Why can steel HPB300, steel plate without Q300, steel structure manuscript review, but also continued the Q235, why not improve it?

- Carbon steel according to the steel yield strength is divided into 5 grades: Q195, Q215, Q235, Q255 and Q275 of each grade because the quality is divided into A, B, C, D grade, with a maximum of four kinds, some only one; this is just plain carbon steel, the price is cheap, generally not heat treatment. Only quality carbon steel has the value of heat treatment.

- Q: Are steel sheets suitable for data center infrastructure?

- Yes, steel sheets are suitable for data center infrastructure. Steel is a strong and durable material that can provide the necessary structural integrity and support for data center equipment and systems. It is commonly used for server racks, cabinets, enclosures, and other components within data centers. Steel sheets offer stability, protection, and easy customization options, making them a reliable choice for data center infrastructure.

- Q: What is the average weight of steel sheets per square foot?

- The average weight of steel sheets per square foot can vary depending on the thickness and type of steel being used. However, as a general guideline, the weight of mild steel sheets can range from 40 to 100 pounds per square foot. Thicker and heavier steel sheets, such as those used in construction or industrial applications, can weigh up to 200 pounds or more per square foot. It is important to note that these weights are approximate and may vary depending on the specific specifications of the steel sheet.

- Q: Can steel sheets be used for cladding or facades?

- Yes, steel sheets can be used for cladding or facades. Steel is a durable and versatile material that can provide strength, weather resistance, and aesthetic appeal to buildings. It can be shaped and customized to create different designs, textures, and finishes, making it a popular choice for cladding or facades in modern architecture.

- Q: Can steel sheets be used for solar panel mounting structures?

- Yes, steel sheets can indeed be used for solar panel mounting structures. Steel is a strong and durable material that can provide the necessary support and stability for solar panels. It is commonly used for mounting structures due to its high strength-to-weight ratio, corrosion resistance, and cost-effectiveness. Additionally, steel sheets can be easily fabricated and customized to fit specific mounting requirements, making them a popular choice in the construction of solar panel systems.

- Q: Can steel sheets be formed into curved shapes?

- Indeed, curved shapes can be achieved with steel sheets by means of a technique referred to as cold forming or bending. Without the need for heating, cold forming entails exerting pressure upon the steel sheet to reshape it. Roll forming, press braking, and stamping are among the different methods employed to accomplish this process. The malleability of steel enables it to be effortlessly molded into curves, thereby rendering it a versatile substance suitable for a wide range of applications in sectors like construction, automotive, and aerospace.

- Q: How do steel sheets compare to other materials, such as aluminum or copper?

- Steel sheets have several advantages over materials like aluminum or copper. Firstly, steel is known for its exceptional strength and durability. It can withstand heavy loads and resist impacts better than aluminum or copper. This makes steel sheets ideal for applications that require high strength and structural integrity, such as in construction or automotive industries. Additionally, steel sheets have a higher melting point compared to aluminum or copper. This means that steel can withstand higher temperatures without deforming or melting. It makes steel sheets suitable for applications that involve exposure to high temperatures, such as in manufacturing processes or engine components. Moreover, steel sheets have excellent corrosion resistance properties. Steel can be coated with various protective layers, such as zinc or chromium, to enhance its resistance to rust and corrosion. On the other hand, aluminum and copper are more prone to corrosion, especially when exposed to certain environments or chemicals. This makes steel sheets a preferred choice for outdoor applications or structures that require long-term durability. Another advantage of steel sheets is their cost-effectiveness. Steel is relatively cheaper compared to aluminum or copper, especially when considering its strength and durability. This makes steel sheets a more economical choice for various applications, where cost plays a significant role. However, aluminum and copper do have their own advantages. Aluminum is lightweight and has excellent thermal conductivity, making it suitable for applications that require lightweight materials or efficient heat transfer. Copper, on the other hand, has superior electrical conductivity, making it ideal for electrical wiring or components. In summary, steel sheets offer exceptional strength, durability, corrosion resistance, and cost-effectiveness compared to aluminum or copper. However, the choice of material ultimately depends on the specific requirements of the application, such as weight, thermal or electrical conductivity, and environmental factors.

- Q: What is a steel sheet?

- A steel sheet is a flat and thin piece of metal made from steel, commonly used in construction, manufacturing, and various industrial applications.

- Q: How thick are steel sheets available?

- Steel sheets are available in a wide range of thicknesses, depending on the specific requirements of the application. Common thicknesses of steel sheets range from 0.5mm (or 0.020 inches) to several inches thick. The thickness of steel sheets is typically measured in gauge, with lower gauge numbers representing thicker sheets. However, it is important to note that the availability of steel sheets in specific thicknesses may vary depending on the supplier and the type of steel being used.

- Q: Are steel sheets suitable for architectural cladding?

- Architectural cladding can indeed utilize steel sheets. Steel possesses durability and versatility, offering an array of advantages for cladding applications. Its strength and rigidity enable it to withstand harsh weather conditions, including strong winds, heavy rain, and snow. This durability ensures that the cladding will endure for many years without requiring frequent maintenance or replacement. Additionally, steel sheets provide a sleek and modern aesthetic to buildings. They can be finished in various ways, such as painting, powder coating, or applying a metallic finish, allowing for limitless design possibilities. Steel cladding can achieve a contemporary or industrial look, making it a favored choice for both commercial and residential structures. Steel sheets are also highly resistant to fire, pests, and rot, making them a safe and long-lasting option for cladding. Furthermore, they are relatively lightweight, which can reduce construction costs and simplify installation. Furthermore, steel is an environmentally friendly material. It is recyclable, making it a sustainable choice for cladding. Steel cladding can also enhance energy efficiency by providing better insulation and reducing heat transfer, resulting in reduced energy consumption for heating and cooling. In conclusion, steel sheets are a suitable choice for architectural cladding due to their durability, aesthetic appeal, safety features, sustainability, and energy efficiency benefits.

Send your message to us

Print Prepainted Galvanized Steel Coil Wooden Pattern For House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords