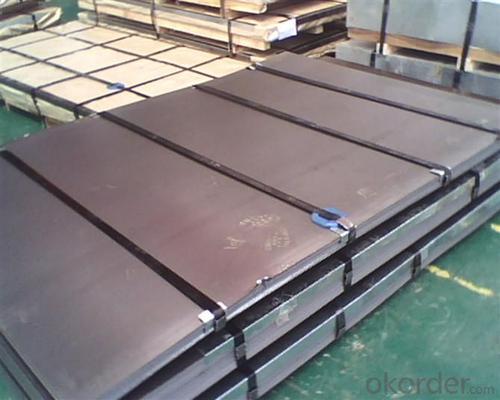

Prime quantity Cold Rolled Steel Coils/Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Name | Cold Rolled Sheet Coil |

Material | SPCC/SPCD/SPCE/DC01/ST12/ ST14/SPCD/DC03/DC04 ect. |

Grade Standard | JIS G3302, EN10142, ASTM653, ASTM95 |

Thickness | 0.15-3.5mm |

Width | 600mm-1500mm |

Coil ID | 508-610mm |

Coil OD | max 1500mm |

Weight | 3-10 Tons |

Tolerance | Thickness tolerance:+/-0.02mm; Width tolerance:+/-5mm |

Surface | No-skin passed or Skin passed, Tensile leveled |

Surface Treatment | Chromate/Unchromate passivation, fingerprint resistant treatment, oiled/unoiled |

Annual Output | 350,000MT |

Application | Construction, hardware, home applicances, interior decoration |

General Application of Cold Rolled Steel Coil:

Classification | Designation | Characteristics | Main applications |

Commercial quality | SPCC SPCCT | Commercial quality suitable for bending fabrication and simple forming; this is the type in greatest demand. | Refrigerators, cabinets, power distribution baords and drums. |

Drawing quality | SPCD | Drawing quality second only to that of SPCEN. Excellent uniformity. | Automobile floor and roof panels. |

Deep-drawing quality | SPCE SPCF | Deep-drawing quality.With metallurgically controlled grain size, it retains its beautiful finish even after being deep-drawn. | Automobile fenders and quarter panels |

Extra deep-drawing quality | SPCG | Extra-low-carbon steel sheets with highest workability | Automobile internal panels and deep-drawn parts |

- Q: I was reading about the Colt 38 Super Custom and it said it's optional between a carbon steel frame or a stainless steel frame. What is the difference? There is also a choice between aluminium or stainless steel hammers and triggers can you also tell me the difference between them please?

- stronger Carbon Steel or Stainless Steel

- Q: How many inches of steel can an AK47 using 7.62x39mm rounds penetrate through?

- A very thin layer of steel. I've fired the AK47 at tanks, ofcourse that wouldn't penetrate but it's not going to penetrate anything crazy. It is a strong Assault Rifle don't get me wrong.

- Q: Will a stainless steel mesh screen scratch a titanium cup, or vice versa?I have a titanium french press and am thinking about replacing the included press with an all steel one. I am worried about little flakes of titanium or steel getting ground off into the coffee when the press slides in and out. The original press has a polyester cloth for a screen, so nothing scratches.

- Will Titanium Scratch

- Q: What are the main applications of steel coils?

- The main applications of steel coils include manufacturing of automobiles, construction materials, appliances, machinery, and various industrial sectors. They are also used in the production of pipes, tubes, roofing, and packaging materials.

- Q: How are steel coils used in the production of construction materials?

- Due to their strength, durability, and versatility, steel coils find widespread usage in the manufacturing of construction materials. Typically made from high-quality steel, these coils are shaped into continuous, cylindrical forms. In the realm of construction material production, steel coils serve different purposes. One primary application involves their use in the creation of steel beams, vital components in constructing buildings, bridges, and other structures. By processing and shaping the steel coils to the desired dimensions, they can easily be formed into beams capable of bearing heavy loads and providing structural support. Another significant utilization of steel coils in construction materials lies in the production of roofing materials. Transforming these coils into corrugated sheets, which are commonly employed as roofing panels, proves highly beneficial. Steel's durability and ability to withstand harsh weather conditions make it an ideal choice for safeguarding buildings against rain, snow, and strong winds. Moreover, these steel coils can be coated with protective layers to enhance their longevity and prevent corrosion. In addition, steel coils play a crucial role in fabricating construction materials such as pipes, tubes, and poles. By shaping the coils according to desired specifications, robust and reliable components for infrastructure projects can be created. Whether for underground pipelines, structural support systems, or utility poles, steel coils provide the necessary strength and durability required for these construction materials. Furthermore, steel coils assume a vital role in the production of construction materials employed in the fabrication of various fixtures and fittings. Through processing and shaping, steel coils can be transformed into door frames, window frames, reinforcement bars, and wire mesh, among other essential elements. This versatility allows for the creation of a wide range of construction materials indispensable for completing buildings and infrastructure projects. In conclusion, the utilization of steel coils in the production of construction materials is driven by their strength, durability, and versatility. Whether in the form of steel beams, roofing materials, pipes, or fixtures, these coils are molded into various shapes and sizes that cater to the specific requirements of construction projects. The incorporation of steel coils guarantees that construction materials possess strength, reliability, and the ability to withstand the demands of the built environment.

- Q: How are steel coils processed before they are used in manufacturing?

- Steel coils undergo several processing steps before they are used in manufacturing. The first step is called pickling, where the coils are immersed in an acid bath to remove any surface impurities, such as rust or scale. This helps to improve the surface quality of the steel. After pickling, the coils go through a process called cold rolling. This involves passing the coils through a series of rollers to reduce their thickness and improve their dimensional accuracy. Cold rolling also enhances the mechanical properties of the steel, making it stronger and more durable. Next, the coils are annealed, which involves heating them to a specific temperature and then slowly cooling them. Annealing helps to relieve internal stresses in the steel and improves its formability and ductility. Following the annealing process, the coils may undergo additional surface treatments, such as galvanizing or coating. Galvanizing involves applying a layer of zinc to protect the steel from corrosion, while coating can involve applying various types of paint or polymer to enhance the steel's appearance or provide specific functionalities. Once the coils have been processed and treated, they are typically cut into smaller sheets or strips, depending on the manufacturing requirements. These sheets or strips can then be used in various manufacturing processes, such as stamping, forming, welding, or fabrication, to create a wide range of products, including automotive components, appliances, construction materials, and many others. In conclusion, steel coils undergo a series of processing steps, including pickling, cold rolling, annealing, and surface treatments, before they are ready to be used in manufacturing. These processes improve the quality, strength, and formability of the steel, allowing it to be transformed into a variety of products.

- Q: And by how much? I'm pretty sure that sterling silver is stronger, but I'm wondering if I could still use a metal stamp to stamp into something that's stainless steel - if it would be soft enough?

- Advantages of sterling silver: * This metal is quite easy for jewelry-makers to work with; therefore, it is simpler for them to create more intricate types of pieces with sterling silver. * The tarnish that can develop on sterling silver is well-liked by some people. Disadvantages of sterling silver: * The aforementioned tarnish is not so well-liked by other people; some people dislike how sterling silver looks as it ages. * Because this material is so soft, it is susceptible to dings, dents, and scratches. Advantages of stainless steel: * Stainless steel pieces will not oxidize or tarnish at all. * Many people find it to be shinier than sterling silver because it offers great light reflection when it is polished to look like chrome. * Stainless steel can also be brushed to look like pewter, too. * Stainless steel is extremely durable and will resist dents, scratches, and chips better than most any other jewelry material. * The cost of stainless steel is quite affordable - much more so than jewelry pieces made from other materials. Disadvantages of stainless steel: * People may know that you have not spent a lot of money on a piece of jewelry (this may or may not be an issue for some jewelry wearers).

- Q: I have a bottle like this* Can u make hot chocolate in it. Can i heat it.I wanna take hot Chocolate to school

- Stainless Steel Water Can

- Q: So I was thinking about doing corset waist training and I wanted to know where I can get a real steel boned corset?

- Hi, okorder / There are 3 types of corsets: Fashion corsets, Authentic corsets and Waist training corsets. The fashion corsets are designed for light enclasping of body. They are made with plastics bones usually. The authentic corsets can reduce your waist size about 4 - 5 and the waist training corsets about 6. They both are made with steel spirals and flat bones. The waist training corsets are recommended for experienced wearers only. Look on info pages of the seller. The corsets reinforced with plastic bones are cheap with low durability.

- Q: How are steel coils used in the manufacturing of railway wagons?

- Steel coils are used in the manufacturing of railway wagons as they serve as a raw material for various components such as the wagon body, chassis, and structural parts. These coils are processed, cut, and shaped to form the required parts, ensuring the wagon's strength, durability, and load-bearing capacity. The steel coils are transformed into sheets, plates, or beams, which are then welded, bolted, or riveted together to construct the wagon's framework and body. Overall, steel coils play a vital role in providing the necessary strength and structural integrity to railway wagons.

Send your message to us

Prime quantity Cold Rolled Steel Coils/Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords