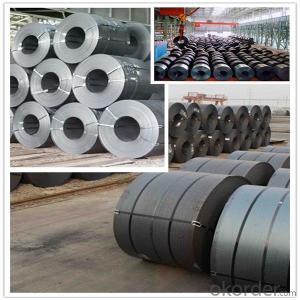

Prime Hot rolled steel sheets/steel coils China supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Detailed Product Description

1.Product Information:

Item | Specification |

Commodity Name: | Galvanized Steel Coil (HDGI/GI) |

Thickness(mm): | 0.14mm-3.0mm |

Width(mm): | Above 600mm to 1500mm, negotiable about "below 600mm" |

Zinc Weight: | 30 g/m2 - 275 g/m2 |

Grade: | Mainly Prime, Secondary is also negotiable |

Material: | SGCC, DX51D+Z,DX53D+Z,DX54D+Z,SGH340, etc |

Spangle: | Zero, Minimum, Regular, Big |

Oiled or Not: | As Required |

Anti Fingerprint or Not: | As Required |

Chromed or Not: | As Required |

Passivation or Not: | As Required |

2. Business Scope:

We provide GI, GL, PPGI, PPGL Coils, Corrugated Steel Sheets, feel free to contact for detailed information!

3. Advantage of Our Organization:

We specialize in this field concerning GI, GL, PPGI, PPGL, Corrugated Steel sheet, we know the supplier, the price, the trader, the domestic market and the price trend very well.

4. FAQ

1. Q: Where is your company located? How can I visit there?

A: Our company is located in Beijing, China. Welcome to visit us.

2. Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

3. Q: What's the MOQ?

A: Our MOQ is 25mt.

4. Q: What's the delivery time?

A: It will take about 30 days after TT or L/C.

5. Q: What is the payment terms?

A: T/T, L/C at sight

6. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

7. Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: Can steel coils be coated with silicon?

- Yes, steel coils can be coated with silicon.

- Q: Nickel is ferro magnetic in nature. But when it is added with stainless steel, it makes stainless steel non-magnetic. What is the structural changes happened with the presence of nickel?

- Steel is magnetic because of the alignment of the spin in the electrons of the atoms in the crystaline matrix of the steel. Nickel atoms are not the same size as Iron atoms and Chromium atoms. by having several different sizes of atoms in the alloy, it prevents a uniform crystaline matrix from being formed. If you imagine a box of marbles that are all the same size, they will all settle into a regular pattern in the box. But a bunch of mismatched marbles will be jumbled together in irregular patterns. This prevents the magnetic properties of either element from asserting itself.

- Q: i cant find this stuff about steel:conductivitystrengthcorrosion resistancecommon applicationsif you know of any interesting facts, i could use those 2!thanx!

- The strength and corrosion resistance depends on the mix. Pure steel is pure iron plus 6% pure carbon. It is the carbon molecules that give it a tough crystallized strength. Pure iron is wrought iron and you can bend that with your hands. Strength also depends on the shape of the beam the most common steel beam is the W flange more commonly called the I beam. That is because the strength of the ‘I’ beam is just a little bit less than if the entire I beam was filled in; however the weight and material savings is huge. Steel itself has no corrosion resistance and is often given a zinc coating just to resist oxidization. Manganese, vanadium and tungsten are just some of the other elements added to improve the steel.

- Q: What is the average lifespan of a steel coil?

- The average lifespan of a steel coil can vary depending on several factors. These factors include the quality and type of steel used, the conditions in which the coil is stored or used, and the maintenance and care it receives. Generally, a well-maintained steel coil can last anywhere from 10 to 30 years. However, this is just an estimate and the actual lifespan can be shorter or longer depending on the aforementioned factors. For instance, if the steel coil is exposed to harsh environmental conditions, such as extreme temperatures or corrosive elements, its lifespan may be reduced. Regular maintenance and proper storage can significantly extend the lifespan of a steel coil. This includes ensuring that the coil is stored in a dry and protected environment, regularly inspecting and addressing any signs of corrosion or damage, and conducting routine cleaning and lubrication as needed. Ultimately, the average lifespan of a steel coil is dependent on various factors, and it is best to consult the manufacturer or industry experts for a more accurate estimate based on specific circumstances and conditions.

- Q: I need to penetrate steel on my car but don't know which bit to use. Are there special bits for steel?

- it's go through steel buddy. But i would imagine that a majority of your standard bits out there will do it. I know there are material specific bits but i would say if you didn't have real expensive drill bits I would try pretty much any of them. If you are talking about the frame of your car or something that thick, then a heavy-duty would be necessary. Don't go drop a lot of money on a diamond bit unless you just keep tearing them up trying to drill through whatever it is you're trying to accomplish. Ive seen wood bits go through some heavy duty metal, so give it a try and save some money.

- Q: How are steel coils used in the manufacturing of industrial mixers?

- Steel coils are used in the manufacturing of industrial mixers as they provide a strong and durable structure for the mixer body. The coils are shaped and welded to create the necessary components, such as the mixing chamber and blade supports. This ensures that the mixer can withstand the high forces and vibrations involved in mixing large quantities of materials in industrial applications.

- Q: How do steel coils perform in high-temperature applications?

- Steel coils perform well in high-temperature applications due to their excellent heat resistance and structural stability. The high melting point of steel allows it to maintain its strength and shape even at elevated temperatures, making it suitable for various industries such as automotive, construction, and manufacturing. Additionally, steel coils can withstand thermal expansion and contraction without warping or deforming, ensuring reliable performance and durability in extreme heat conditions.

- Q: What is the thickness range of steel coils?

- The thickness range of steel coils can vary depending on the specific application, but it typically ranges from 0.005 inches to 0.5 inches.

- Q: Its big and expensive and i don't know if it would have a logical purpose but its sharp as hell and awesome. Anyways, its made from surgical steel and all i have found on the internet is that its probably 316L (w/e that means). I have another knife made from 440 stainless steel and as far as i know that is pretty much the hardest stainless metal. So why would the more expensive one be made from surgical steel?

- Surgical Steel Knife

Send your message to us

Prime Hot rolled steel sheets/steel coils China supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords