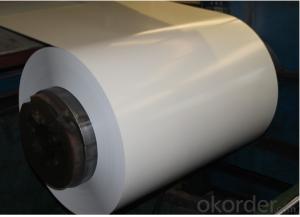

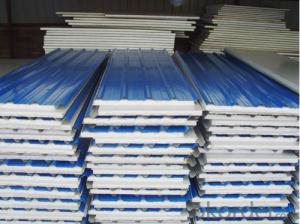

Prime PPGI Prepainted galvanized steel coils sheets good price from China for roofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prepainted GI steel coil / PPGI / PPGL color coated galvanized steel sheet in coil

Specificaton

Thickness | 0.15mm-3.5mm |

Thickness tolerance | ±0.02mm |

Width | 600--1500mm all available |

Width tolerance | ±2mm |

Length | 1000-6000mm or as to client require |

Zinc coating | 40g/m2-275g/m2 |

Types | Commercial / Drawing / Deep Drawing / Structural quality |

Quality | Soft or hard quality |

Standard | ASTM, AISI, DIN, GB,JIS |

Material | SGCC, DX51D,DX52D, DX53D,SGCD , Q195, Q235, SGHC, DX54D, S350GD, S450GD, S550GD, etc |

Spangle State | Regular spangle, small spangle, big spangle, non-spangle |

Surface treatment | chromed / oiled/slightly oiled/ dry/ anti-fingerprint etc |

Coil weight | 3-8ton or as client requirement. |

Coil ID: | 508 /610mm |

Packing | Export standard. |

Min order | 50 tons |

Mechanical Properties | |||

Grade | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+AZ) | ≥205 | ≥270 | ≥22 |

SGCD(DX52D+AZ) | ≥140 | ≥270 | ≥38 |

S250GD+AZ | ≥250 | ≥330 | ≥19 |

S350GD+AZ | ≥350 | ≥420 | ≥16 |

Aplications

1.Refrigerator shutter &side panels,

2.household appliances,Washer,Freezers

3.Computer/ DVD/DVB Panels , etc.

- Q: How can I judge the quality of steel?

- Various ways: Carry out mechanical testing on it to see how strong it is. eg. Tensile testing, hardness testing, impact testing. Examine a cleaned up sample on the steel under a microscope to see what the steel grain structure is like and what condition it is in (hardened etc.) Or the easiest way is to ask the supplier what it is and then find a specification sheet giving you all the above information.

- Q: How are steel coils processed for painting or coating?

- Steel coils are processed for painting or coating through a series of steps. Firstly, the coils are cleaned to remove any dirt, oil, or scale using various methods like acid pickling or mechanical cleaning. Then, a primer or chemical treatment is applied to enhance the adhesion of the paint or coating. Next, the coils are dried to remove moisture and ensure proper adhesion. Finally, the paint or coating is applied to the coils using methods such as coil coating or electrostatic spraying, and then the coated coils are cured to achieve the desired finish and durability.

- Q: How much does a steel coil weigh?

- The weight of a steel coil can vary depending on its size, thickness, and type of steel used. Generally, a standard steel coil can weigh anywhere from a few hundred pounds to several thousand pounds.

- Q: What are the different types of steel coil coatings for heat resistance?

- Heat resistance is achieved through the use of different types of steel coil coatings. These coatings are designed specifically to safeguard the steel surface, preventing it from deteriorating or oxidizing under high temperatures. Organic coatings, such as epoxy, polyester, or polyurethane, are commonly used. They form a protective barrier against heat and prevent the steel from corroding or oxidizing. Organic coatings are typically employed in situations where moderate heat resistance is necessary. Another option is inorganic coatings, made from ceramic or metallic materials. These coatings offer excellent heat resistance and can endure extremely high temperatures. Industries like automotive, aerospace, and power generation frequently utilize inorganic coatings, as their components are exposed to intense heat. Specialized coatings are also available to meet specific heat resistance requirements. Silicone coatings, for instance, exhibit exceptional heat resistance and can withstand temperatures reaching 600°C (1112°F). They find common use in applications like exhaust systems, ovens, and industrial furnaces. Some steel coil coatings may also incorporate additives or fillers to enhance their heat resistance properties. These additions improve the coating's ability to withstand high temperatures and provide superior protection against heat-related issues. In conclusion, a range of steel coil coatings is available for heat resistance, including organic coatings, inorganic coatings, and specialized coatings. The choice of coating depends on the specific heat resistance requirements of the application. Factors such as temperature range, duration of exposure, and environmental conditions must be taken into account when selecting the appropriate coating.

- Q: What are the different methods of corrosion protection for steel coils?

- There are several methods of corrosion protection for steel coils, including but not limited to: 1. Coating: Applying a protective layer such as paint, polymer, or zinc coating on the surface of the steel coil to prevent direct contact with corrosive agents. 2. Galvanizing: Immersing the steel coil in a bath of molten zinc, creating a protective coating that prevents corrosion. 3. VCI (Vapor Corrosion Inhibitor): Using volatile corrosion inhibitors that release molecules to form a protective layer on the steel coil, preventing corrosion. 4. Oil or Wax Coating: Applying a layer of oil or wax on the surface of the steel coil to act as a barrier against moisture and corrosive elements. 5. Cathodic Protection: Using sacrificial anodes or impressed current to protect the steel coil by providing a more easily corroded metal that attracts corrosion instead. 6. Desiccants: Placing desiccant materials such as silica gel or molecular sieves inside the packaging to absorb moisture and prevent corrosion. 7. Environmental Control: Maintaining controlled humidity levels, temperature, and proper ventilation in storage areas to minimize the risk of corrosion. 8. Proper Handling and Storage: Implementing safe handling practices during transportation and storing steel coils in dry, covered areas away from corrosive substances. It is important to select the appropriate method based on the specific application, environment, and desired level of protection for the steel coils.

- Q: ive made lots of knives but they are dark and not shiny. how do i polish a knife and make it shiny

- Look for buffing compound at the hardware store. Home depot lowe's od even Wal-mart/ There is a compound for steel and for iron. I t will not make iron real shinny but it will make it look good. This stuff is to be used with a buffing wheel but I have used it on rags and it work great.

- Q: What are the properties of high-strength steel coils?

- High-strength steel coils possess several distinct properties that make them highly desirable in various industrial applications. Firstly, these coils exhibit exceptional strength, meaning they have a high tensile strength and can withstand significant amounts of force or weight without deformation or breakage. This property allows them to be used in demanding environments or for heavy-duty purposes. Another key property of high-strength steel coils is their excellent resistance to wear and tear. They have a high level of hardness, which enables them to resist abrasion, impact, and other forms of mechanical stress. This makes them ideal for applications where durability and longevity are crucial, such as in construction, automotive manufacturing, and machinery production. Additionally, high-strength steel coils often possess excellent corrosion resistance. They are typically coated or treated with protective materials to prevent rust or other forms of deterioration caused by exposure to moisture, chemicals, or harsh environmental conditions. This corrosion resistance property ensures the longevity and reliability of the coils, making them suitable for applications in marine environments or outdoor structures. High-strength steel coils also offer good formability, meaning they can be easily shaped or bent without losing their strength or integrity. This property allows manufacturers to create complex or custom shapes for specific applications, enhancing their versatility and adaptability. Lastly, high-strength steel coils are known for their light weight compared to other materials with similar strength properties. This low weight-to-strength ratio makes them a preferred choice in industries where weight reduction is crucial, such as aerospace or automotive manufacturing. It allows for improved fuel efficiency, increased payload capacity, and overall cost savings. In summary, high-strength steel coils exhibit properties such as exceptional strength, resistance to wear and tear, corrosion resistance, formability, and light weight, which make them valuable and versatile materials in various industries.

- Q: If I wear a pair of thick wool socks, is walking around in the snow with steel-toed boots going to be a problem? I'm wondering if the steel will make my toes too cold.

- Dr. Martens makes a number of pairs of steel toed work boots. I have never owned a pair of their steel toes, but I have owned several pairs of their shoes and boots, the oldest of which is fifteen years old and still going strong. They take a couple of weeks to break in, but once they do, they are practically molded to your foot. They are more expensive, but they last a LONG time. Good Luck!

- Q: How are steel coils used in the manufacturing of exhaust manifolds?

- Steel coils are used in the manufacturing of exhaust manifolds as they provide the raw material for creating the manifold's structural components. These coils are typically cut, shaped, and welded to form the intricate and durable design required for efficient exhaust gas flow.

- Q: Is there much difference? Which is better? Are they equally safe? Is it just personal preference? Can you reccomend a good comfortable steel composite toe boot?

- steel toe boots are just that a piece of steel fitted over the toes, composite toe boots use other materials that are just as hard BUT they do not have the connectivity levels as steel. if you are working in a cold climate steel toes will freeze them toes right off, also electrical environments. my advice get a good pair of composite ones, and you get what you pay for, its worth the investment. more than you could ever imagine. proper foot support. helps legs cramps, back pain etc...

Send your message to us

Prime PPGI Prepainted galvanized steel coils sheets good price from China for roofing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords