Prime Hot Rolled Chequered Steel Sheets China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM,GB,JIS

Technique:

Hot Rolled

Shape:

Round

Surface Treatment:

Galvanized,Oiled,Dry

Steel Grade:

Q195,Q215,Q235,SS400-SS490

Certification:

ISO,SGS,BV,CE

Thickness:

1.8mm-16mm

Width:

1000mm-1600mm

Length:

requirement

Net Weight:

23mt

Packaging:

Standard Export Packing

Product Description:

| Grade | Q235B,Q345B,SS400ASTM A36, St37-2 |

| Standard | GB, BS, EN, ASTM, JIS |

| Payment | L/C |

| Delivery | 25 working days after confirmed the order |

| Application | Floor board, factory stair boards, deck board, car boards ,staircases, lorry beds, elevator floors |

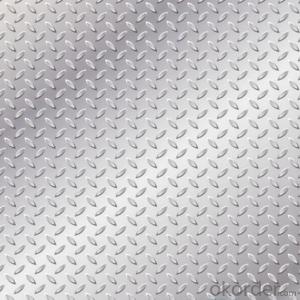

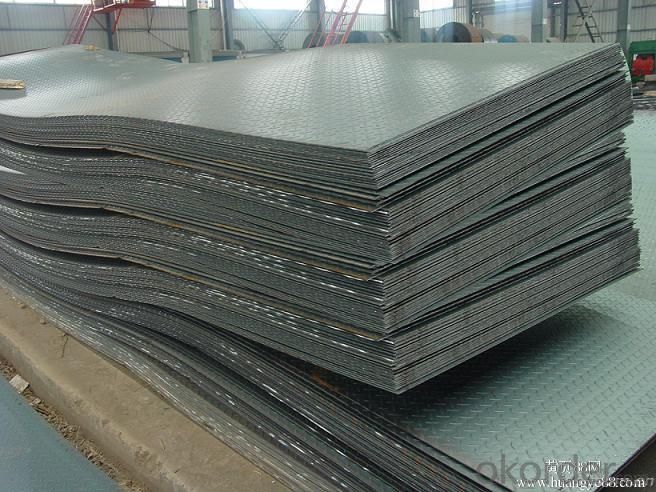

2.Product Images

3.Our Service

4.FAQ

1. Q: Where is your company located? How can I visit there?

A: Our company is located in Beijing, China. Welcome to visit us.

2. Q: What's the MOQ?

A: Our MOQ is 23mt.

3. Q: What's the delivery time?

A: It will take about 30 days after TT or L/C.

4. Q: What is the payment terms?

A: T/T, L/C at sight

5. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

- Q: Why does steel with several composites have a greater hardenability from quenching than low carbon steel alloys?Any help would be great

- Bit tricky to explain and I don't know muh about it but steel on its own has lost of gaps in it ( the molecular structure) and when carbon is added thos gaps are filled, I think of it like this: it is easier to punch through expanded polystyrene( with all the little balls) than unexpanded(just a lump of plastic) as the balls are not properly joined and have air pockets between them.

- Q: How are steel coils used in the manufacturing of industrial compressors?

- Steel coils are used in the manufacturing of industrial compressors as a crucial component for constructing the compressor's internal structure, such as the casing and housing. The steel coils provide strength, durability, and stability to the compressor, allowing it to withstand high pressure and temperature conditions. Additionally, the coils are often used in the construction of the compressor's motor, providing support and ensuring efficient operation. Overall, steel coils play a vital role in the manufacturing of industrial compressors by providing the necessary structural integrity and functionality.

- Q: How are steel coils processed at the steel service centers?

- Steel service centers process steel coils through a series of steps to transform them into finished products that meet the specific requirements of customers. The process typically begins when the steel coils arrive at the service center. These coils are usually large and heavy, and they may have been produced by a steel mill or imported from overseas. Upon arrival, the steel coils undergo a quality inspection to identify any defects and ensure that only high-quality coils are used in the production process. After inspection, the coils are stored in a warehouse until they are ready for processing. Next, the steel coils are uncoiled to create flat sheets of steel. This can be done manually or using automated machines, depending on the size and thickness of the coils. The uncoiled steel is then leveled to remove any residual stress and ensure a flat and consistent surface. Once leveled, the steel sheets go through various processes based on the desired end product. These processes may include cutting, shearing, slitting, and forming. Cutting and shearing involve shaping the steel sheets into specific sizes or shapes. Slitting involves cutting the steel into narrow strips, while forming involves bending or shaping the steel. After the desired processing operations are completed, the steel sheets are often treated with surface finishes to enhance their appearance or protect them from corrosion. These finishes may include painting, coating, or galvanizing. Finally, the processed steel sheets undergo another quality inspection to ensure they meet the required specifications. They are then packaged and prepared for shipment to customers in industries such as construction, automotive, or manufacturing. Overall, the processing of steel coils at steel service centers involves a combination of inspection, uncoiling, leveling, cutting/shearing/slitting/forming, surface finishing, quality control, and packaging. This process allows for the transformation of steel coils into finished products that are customized to meet the specific needs and requirements of customers.

- Q: which pokemon has the most steel pokemon???

- Transformers.

- Q: What are the main factors that affect the flatness of steel coils?

- The main factors that affect the flatness of steel coils include the quality and consistency of the incoming raw material, the precision of the rolling process, the tension applied during rolling, the cooling and annealing processes, and the handling and storage of the finished coils.

- Q: Is sterling silver better than surgical steel as far as being hypoallergic in earrings? If I have a choice which should I get? Thanks!

- Surgical okorder /

- Q: Well im currently doing a project. Wanna help me? Because trust me, i really need it. You know how steel was created in China? If you didnt, you just learned something newww(: but anyways got any info on that? Websites? or just info from websites? Well lemme know because if its the best you get Best Answer Easy points right? (: Okay thanksss (:

- Steel is created in a primitive way whenever iron oxide ore (red dirt) is mixed with wood and burned. Seemingly everyone has a pet theory how their own selected country was the first to notice and do it on purpose. Regards, Larry.

- Q: How are steel coils used in the production of shipbuilding materials?

- Steel coils are used in the production of shipbuilding materials as they provide a convenient and efficient way to transport and store large quantities of steel. These coils are uncoiled and cut into desired sizes to construct various components of ships, such as hulls, decks, and superstructures. The versatility and strength of steel make it an ideal material for shipbuilding, and the use of coils ensures a reliable supply chain for this crucial industry.

- Q: In terms of weight to strength titanium is stronger. But is it stronger than mild steel? If it is stronger, how much stronger is it?

- Contrary to what we are usually told, Ti weight to strength ratio is better only for lower strength alloys. Steels match or best Ti and Al alloy ratio's for high strengths. Hard to answer this question, due to varying effects of cold work, alloying, and heat treatments. In general, traditional mild steels with little cold work are about equivalent strength to commercially pure Ti. Cleverly selected mild steels with extensive cold work have greater UTS (and really greater SMYS) than commercially pure Ti, and approach strength of the best Ti alloys. Ti starts at about 60ksi UTS for commercially pure, and goes up to about 200ksi for high strength alloys. Mild steel has varying definitions. Plain carbon steels use virtually no alloying materials other than carbon. Low carbon steels starting in the 1008 (0.08% carbon) range can be cold worked to 100ksi UTS, while 1030, the maximum carbon for mild steel per one source, can be cold worked up to about 180ksi. Simple steels can go about 215 ksi UTS at fairly reasonable cost with lesser cold work than I was using because producers can't make stronger steels with higher degrees of cold work. High strength alloys can best 350ksi at impressively high cost. (and they match best titanium alloy strength to weight ratio). They are why wide body aircraft have lots of steel - landing gears, flap mechanisms, etc. Don't know about cold working Ti though. It doesn't seem to be done much, but difficult to find info.

- Q: The Chinese invented the windmill long before the 1800's, but I cannot find anywhere who invented the steel windmill, I believe it was in the 1800'sIf you know the answer that'd be great!And also if you could find the date it was patented? Thanks SO much!

- The Steel Eclipse Type WG was the first of several self-oiling steel windmills marketed by Fairbanks, Morse, and Company after they became the distributor of all the Eclipse mills about the start of the 20th Century. It has the more important distinction of having been the only widely distributed worm-gear mill in the history of American windmill manufacture. Produced from about 1926 to the mid-1930's, the Steel Eclipse remains in the field today in considerable number in most parts of the country. Hope this helps!

Send your message to us

Prime Hot Rolled Chequered Steel Sheets China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords