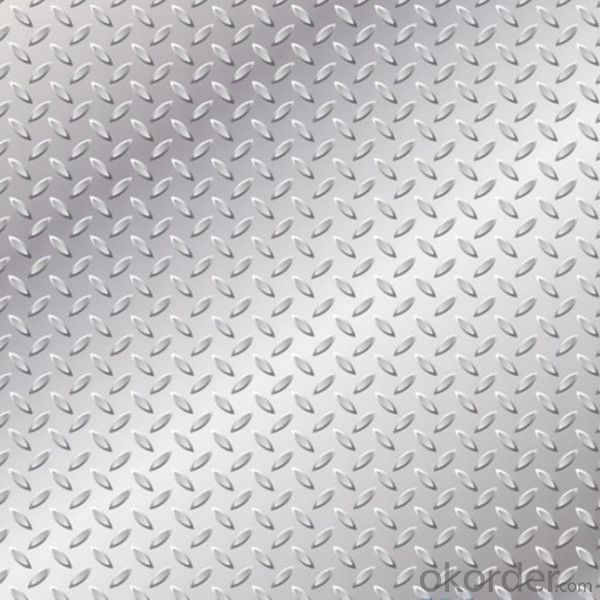

Prime Hot Rolled Steel Chequered Sheets China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM,GB,JIS

Technique:

Hot Rolled

Shape:

Round

Surface Treatment:

Galvanized,Coated,Oiled,Dry

Steel Grade:

Q195,Q215,Q235,SS400-SS490

Certification:

ISO,SGS,BV,CE

Thickness:

1.8mm-16mm

Width:

1000mm-1600mm

Length:

requirement

Net Weight:

23mt

Packaging:

Standard Export Packing

Product Description:

1.Brand:Yanshan

2. Standard: ASTM, AISI,BS,DIN

3. Shape: bean or dot shape, or as customer's request

4. Size: 1.5-20 mm thickness, width: 1000-1600mm

5. Length: as required

6. Productivity: 10000 metric tons/month

7. Delivery Date: 15-25 days

8. payment terms: Irrevocable L/C at sight

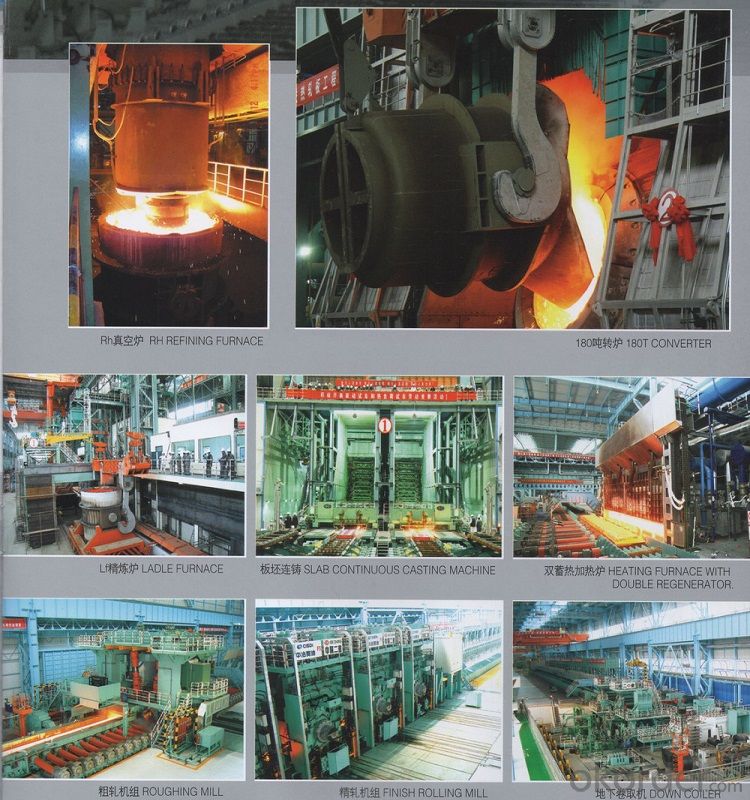

Product Process:

Our Service:

| Delivery time | 20-35days after receiving the payment of 30% deposit. |

| Payment | -Irrevocable L/C at sight. |

| -30% T/T in advance and 70% balance against copy of B/L. | |

| Packing | -Standard Export Packing |

| -According to customer's request. | |

| Load port | Tianjin port, Shanghai port, Ningbo port or customer's request |

| Feedback | If you have any questions, please feel free to contact us at any time possible. |

| We will reply as soon as possible. | |

| After Sale | Any questions of the production, please let me know directly by email or phone. |

| We can deal with these issues on time, promise give you happy answers. | |

| We focused on the after sale. Welcome send any comments to us. |

- Q: How are steel coils coated for specific applications?

- Steel coils are coated for specific applications using a process called coil coating. In this process, the steel coils are cleaned, treated, and then coated with a layer of paint or other protective material. The coating is applied evenly and precisely to ensure optimal performance and durability in the intended application.

- Q: Is there any noticable or perceived difference between smoking out of a pipe with a brass screen and a stainless steel screen?

- I have been searching the internet, trying to find out the difference, myself... I know what I have heard from others; that the stainless steel is more rigid, and harder to mold to the bowl. I've heard that brass is softer, and previously thought it was healthier, but someone recently told me the opposite to what I'd heard. The one thing I do know for sure is that you're supposed to heat both sides of either with a lighter to oxidize anything that doesn't need to be there... If you do find the answer, I'd love to hear it... Cheers!

- Q: How do steel coils contribute to the agricultural machinery industry?

- Steel coils are an essential component in the agricultural machinery industry due to their versatile and durable nature. They are used in various applications and play a crucial role in improving the efficiency and productivity of agricultural machinery. One of the primary ways steel coils contribute to the agricultural machinery industry is through their use in the manufacturing of equipment frames and structures. These frames provide the necessary strength and stability to withstand the demanding conditions of agricultural operations. Whether it is in tractors, harvesters, or tillers, steel coils are used to create sturdy and rigid frames that can handle heavy loads, vibrations, and impacts. Additionally, steel coils are used in the fabrication of components such as plow blades, cultivator tines, and seed drills. These components are crucial for soil preparation, seed planting, and crop maintenance. Steel coils provide the necessary strength and resistance to wear and tear, ensuring these components can withstand the rigors of agricultural operations and last for extended periods. Furthermore, steel coils are also used in the manufacturing of hydraulic systems and other moving parts in agricultural machinery. These systems are responsible for powering and controlling various functions, such as lifting, lowering, and steering. Steel coils provide the necessary strength and flexibility for these systems to function optimally, ensuring smooth and efficient operation of agricultural machinery. Moreover, steel coils contribute to the agricultural machinery industry by enhancing the safety and longevity of the equipment. Steel is known for its excellent resistance to corrosion, rust, and extreme weather conditions. By using steel coils in the construction of agricultural machinery, manufacturers can ensure that the equipment remains durable and reliable even in harsh environments, ultimately reducing maintenance costs and improving the overall lifespan of the machinery. In conclusion, steel coils are an indispensable component in the agricultural machinery industry. Their versatility, strength, and durability make them crucial for the manufacturing of equipment frames, components, hydraulic systems, and other moving parts. By utilizing steel coils, the agricultural machinery industry can produce robust and efficient equipment that can withstand demanding agricultural operations, improve productivity, enhance safety, and extend the lifespan of the machinery.

- Q: What are the applications of steel coils in the aerospace industry?

- Steel coils have several important applications in the aerospace industry. One of the key uses is in the manufacturing of aircraft structures. Steel coils are commonly used in the fabrication of various components such as wing spars, fuselage frames, and landing gear. The high strength and durability of steel make it an ideal material for these critical parts, as they need to withstand heavy loads and extreme conditions. Another application of steel coils in the aerospace industry is in the production of engine components. Steel coils are used to manufacture turbine blades, which are subjected to high temperatures and rotational forces. The excellent heat resistance and mechanical properties of steel make it suitable for these demanding applications, ensuring the reliability and performance of aircraft engines. Steel coils are also utilized in the production of fasteners and connectors used in the aerospace industry. Fasteners such as bolts, nuts, and rivets made from steel coils are crucial for joining different parts of an aircraft securely. These fasteners need to have high tensile strength and corrosion resistance to ensure the structural integrity and safety of the aircraft. Additionally, steel coils find application in the production of fuel tanks and hydraulic systems. The excellent weldability and formability of steel allow for the efficient fabrication of these complex structures. Steel coils can be shaped into different sizes and configurations, providing flexibility in designing fuel tanks and hydraulic components that meet specific requirements. In summary, steel coils play a vital role in the aerospace industry. Their use in aircraft structures, engine components, fasteners, and fuel tanks showcases their versatility and reliability. The exceptional strength, durability, heat resistance, and formability of steel make it a preferred material for various aerospace applications, ensuring the safety and performance of aircraft.

- Q: What are the different surface finishes of steel coils?

- The different surface finishes of steel coils include mill finish, galvanized finish, painted finish, and coated finish.

- Q: I wasn't expecting much because i knew it was cheap (Trying to avoid high prices) But anyway i cut a few bottles and cans and i noticed the very edge of the blade was starting to bend. I ignored it and tried it on a 3 inch limb, and the whole blade bent sideways where the limb hit it.I heard cold steel was supposed to be top quality and I wanted to know how durable their swords are and if they're worth it. Thanks!

- Yes. Cold Steel is a great company with a quality product, and I've always been happy with their work. Their katanas, while not made in the traditional method, are heavy duty carbon steel and should handle abuse well. I'd recommend them based on my experience with other Cold Steel products.

- Q: Can steel coils be used in the automotive industry?

- Yes, steel coils can be used in the automotive industry. Steel coils are commonly used in the manufacturing of various automotive components and parts. They are particularly suitable for applications that require high strength and durability, such as body panels, chassis components, suspension parts, and engine components. Steel coils provide excellent structural integrity, corrosion resistance, and impact resistance, which are crucial characteristics for automotive applications. Additionally, steel coils can be easily formed and shaped into the desired dimensions, making them highly versatile and cost-effective for automotive manufacturers. Overall, steel coils are widely utilized in the automotive industry due to their exceptional mechanical properties and suitability for various automotive applications.

- Q: How do steel coils contribute to the HVACR industry?

- The HVACR industry relies heavily on steel coils, which play a vital role in various applications. These coils, typically made from durable and corrosion-resistant materials like stainless steel or galvanized steel, ensure longevity in demanding HVACR environments. Air conditioning systems commonly use steel coils to transfer heat between the refrigerant and the surrounding air. These coils, also known as evaporator coils, absorb heat from indoor air, cooling it down and removing moisture. The heat is then released outside through a condenser coil, enabling efficient cooling and dehumidification. Heat exchangers, crucial components in HVACR systems, also utilize steel coils. These coils, often in the form of finned tubes, provide a large surface area for efficient heat transfer, enhancing overall system efficiency. In the construction of ductwork, steel coils are extensively employed. These coils are shaped and sized to fit specific ductwork designs, ensuring optimal airflow and temperature control. Their durability and strength allow them to withstand the pressure and forces exerted by airflows in duct systems. Refrigeration systems rely on steel coils to transfer heat out of enclosed spaces, such as refrigerators or freezers. These coils, called condenser coils, release heat from the refrigerant as it changes from a high-pressure gas to a high-pressure liquid. Steel coils are essential in the food service and cold storage industries, where they enable the cooling and preservation of perishable goods. Overall, steel coils significantly contribute to the HVACR industry by facilitating efficient heat transfer, optimal temperature control, and reliable operation of various systems. Their durability, corrosion resistance, and versatility make them crucial components in providing comfortable and controlled environments in residential, commercial, and industrial settings.

- Q: i bought an airsoft gun and it said steel recievers on it im not sure what that is

- It means the receivers are steel, what did you think it meant? I would call steel a bad thing in airsoft, because it's unnecessary and heavy. You'd honestly be better off getting a gun with plastic receivers and buying an aftermarket kit. My GP receivers are very strong, and incredibly light.

- Q: I would like to know the process of making steel from the mining of ore to the final product. Can anybody offer some help? Either where to look, or the process itself. I would like to have included the different options with which to make steel. Through scrap metal, or iron ore briquettes etc... Thanks.

- A okorder /.. There are many different types of steels depending on process and ingredient changes that can be found in many engineering books. This will give you the basic flow.

Send your message to us

Prime Hot Rolled Steel Chequered Sheets China Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords