Hot-Dip Gavalnized Steel Sheet in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

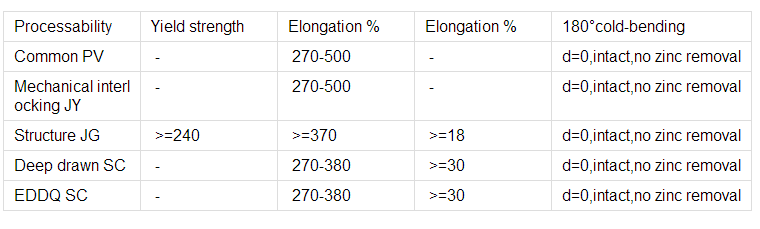

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet :

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What are the common manufacturing defects in steel coils?

- Common manufacturing defects in steel coils include surface defects such as scratches, pits, and dents, as well as internal defects like inclusions, cracks, and voids. Other common defects can include uneven thickness, waviness, and coil set.

- Q: I want to know if Diamond is stronger than Steel.

- diamond are hard but it is not stronger than steel because diamond is a kind of element but the steel is not .steel are influenced by the people

- Q: How long do steel coils typically last?

- Steel coils typically last for decades. The lifespan of steel coils can vary based on several factors including the quality of the steel used, the level of maintenance and care, and the specific application they are utilized in. Generally, steel coils are designed to be durable and resistant to corrosion, ensuring a long lifespan. With proper care, regular maintenance, and adherence to recommended usage guidelines, steel coils can last anywhere from 20 to 50 years or even longer. However, it is important to note that the lifespan can be influenced by external factors such as exposure to harsh environments, extreme weather conditions, and the level of stress or load they are subjected to.

- Q: What are the different steel coil finishes available?

- There are several different steel coil finishes available, including hot rolled, cold rolled, galvanized, and stainless steel finishes.

- Q: How are steel coils inspected for surface cleanliness using cleanliness tests?

- Steel coils are inspected for surface cleanliness using cleanliness tests to ensure that they meet the required quality standards. These tests involve various methods to assess the presence of contaminants, such as dirt, oil, grease, rust, or scale, on the surface of the steel coils. One commonly used cleanliness test is the visual inspection, where trained inspectors visually examine the surface of the coils for any visible contaminants. They look for any signs of staining, discoloration, or foreign substances that may affect the quality of the steel. Another cleanliness test is the wipe test, where a clean cloth or wipe is used to wipe the surface of the steel coil. This cloth is then analyzed for the presence of contaminants using techniques like gravimetric analysis or solvent extraction. The amount of contaminants collected on the cloth can be measured, providing an indication of the cleanliness of the steel surface. Surface roughness tests are also performed to assess cleanliness. A roughness gauge is used to measure the roughness of the steel surface, which can indirectly indicate the presence of contaminants. If the surface roughness measurements are higher than the specified limits, it suggests the presence of contaminants affecting the cleanliness of the steel. In addition to these tests, cleanliness tests may also involve techniques like wetting tension measurement, water break test, or contact angle measurements. These tests evaluate the surface energy and wetting properties of the steel, which can be affected by the presence of contaminants. By conducting cleanliness tests, steel coils can be thoroughly inspected for surface cleanliness. These tests help in identifying any potential contaminants that may compromise the quality and performance of the steel. By ensuring the surface cleanliness of steel coils, manufacturers can provide high-quality products that meet the stringent requirements of various industries.

- Q: What are the different types of steel coil cuts?

- There are several different types of steel coil cuts, including hot-rolled, cold-rolled, galvanized, and stainless steel coil cuts.

- Q: What material is strongest? Human bone, steel, or concrete?

- Takfam is correct, but in the loooong run, concrete will exist for thousands of years after the steel oxidized, deteriorates, and disappears. The ancients compounded concrete even before the Romans (I can't recall but during the time of the Assyrians), and concrete is almost forever.

- Q: Help please.What atoms are there in steel?Like water is equals to 1 Oxygen atom + 2 Hydrogen atoms.Thnx 4 d help.

- Steel is mostly iron with a small amount (less than 1%) of carbon added. Stainless steel has other metals like chromium and nickel added.

- Q: Are they made using the same processes, or is tempered steel made without the quenching process?

- Hardening is the preliminary process. The fully hardened state may be far too brittle for practical use. The tempering process is tailored to reduce the actual hardness, to introduce more flexible alloys. The tempering method employed may be done at relatively low temperatures, but some alloys require prolonged soaking at elevated temperatures. Some may be cooled in air, but others may require quenching to end the process.

- Q: Can steel coils be stacked on top of each other?

- Yes, steel coils can be stacked on top of each other.

Send your message to us

Hot-Dip Gavalnized Steel Sheet in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords