Prime Galvanized Pipe full sizes for greenhouse frames/handrails

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Prime Galvanized Pipe full sizes for greenhouse frames/handrails:

The galvanized pipes are used as

Scaffolding pipe, Structure pipe, Fence/Door pipe, Furniture, Low pressure fluid pipe for

water oil or gas, Boiler pipe

Applicable for greenhouse, building, fences construction, and transferring water .

2、Main Features of Prime Galvanized Pipe full sizes for greenhouse frames/handrails:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Prime Galvanized Pipe full sizes for greenhouse frames/handrails Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

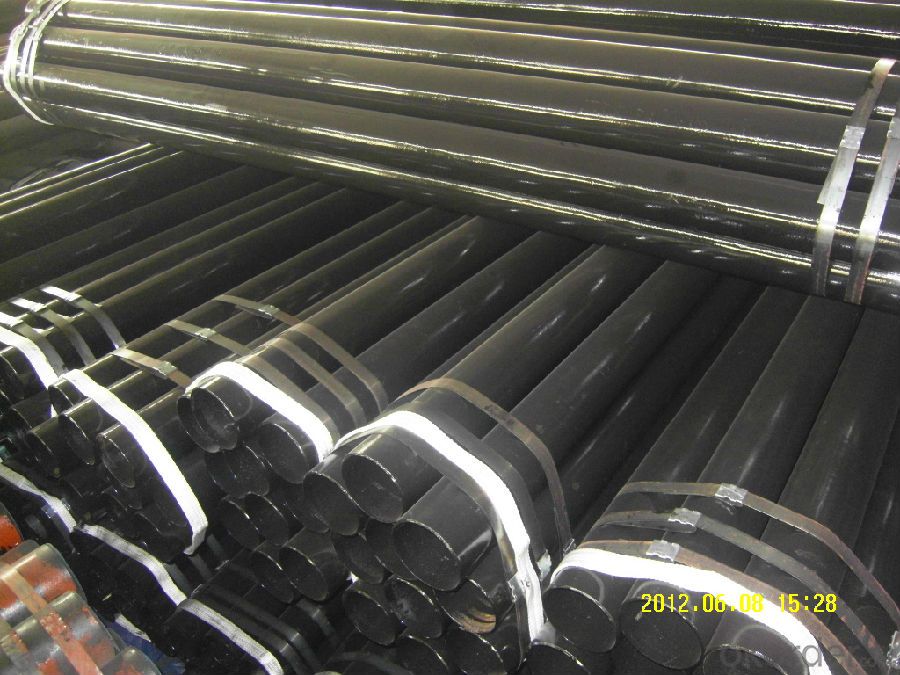

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Prime Galvanized Pipe full sizes for greenhouse frames/handrails :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、Prime Galvanized Pipe full sizes for greenhouse frames/handrails images:

- Q: Can steel pipes be used for water wells?

- Yes, steel pipes can be used for water wells. Steel pipes are commonly used for constructing water wells due to their durability, strength, and resistance to corrosion. They can withstand high water pressure and provide a reliable and long-lasting solution for accessing underground water sources.

- Q: How are steel pipes measured and labeled?

- Steel pipes are typically measured and labeled based on their diameter, wall thickness, and length. The diameter is measured in inches or millimeters, while the wall thickness is often expressed in inches or schedule numbers. The length is usually specified in feet or meters. Additionally, steel pipes may also bear labels indicating the type of steel used, industry standards compliance, and any specific certifications or markings required.

- Q: What is the difference between hot dip galvanized steel pipe and galvanized steel pipe?

- 1, the process is different, one is chemical treatment, one is physical treatment; hot-dip galvanized coating is reliable, not easy to fall off2, hot-dip galvanized coating thickness, so strong corrosion resistance. And zinc plating (electroplating) coating evenly, surface quality is better, coating thickness is generally between a few microns to more than ten microns.3 hot galvanizing is a chemical process, which belongs to electrochemical reaction. Zinc plating is a physical treatment, just brush a layer of zinc on the surface, there is no galvanizing inside, so the zinc layer is easy to fall off. Hot-dip galvanizing is used in building construction.4 、 hot galvanized pipe is to make molten metal and iron matrix reaction and produce alloy layer, so that the substrate and coating two combination.

- Q: What are the common defects found in steel pipes?

- Some common defects found in steel pipes include corrosion, cracks, dents, and leaks. Other defects may include misalignment or misshapen sections, improper welding, and brittleness.

- Q: What are the factors affecting the lifespan of steel pipes?

- There are several factors that can affect the lifespan of steel pipes. 1. Corrosion: Corrosion is one of the primary factors that can significantly reduce the lifespan of steel pipes. Exposure to moisture, chemicals, and other corrosive elements can lead to rusting and degradation of the pipe material over time. 2. Environmental conditions: The environment in which the steel pipes are installed plays a crucial role in their lifespan. Extreme temperatures, humidity, and exposure to various weather conditions can accelerate the corrosion process and weaken the pipe structure. 3. Water quality: The quality of the water flowing through the steel pipes can also impact their lifespan. Water with high acidity or alkalinity levels, excessive chlorine, or other contaminants can cause corrosion and deterioration of the pipe material. 4. Installation quality: The way steel pipes are installed can affect their lifespan. Poor installation practices, such as inadequate support or incorrect alignment, can lead to stress points and structural weaknesses, making the pipes more prone to failure. 5. Maintenance and repair: Regular maintenance and timely repairs are crucial in maximizing the lifespan of steel pipes. Proper cleaning, inspection, and corrosion protection measures can help identify and address potential issues before they progress and cause significant damage. 6. Design and material quality: The design and quality of steel used in pipe manufacturing are important factors in determining their lifespan. High-quality steel with appropriate alloy composition and thickness provides better resistance to corrosion and mechanical stress, ensuring a longer lifespan. 7. Load and pressure: The load and pressure that steel pipes are subjected to can impact their durability. Excessive pressure or frequent variations in pressure can put stress on the pipe walls, leading to fatigue or failure over time. By considering and addressing these factors, it is possible to extend the lifespan of steel pipes and ensure their reliable performance over an extended period.

- Q: Can steel pipes be used for underground power transmission?

- Yes, steel pipes can be used for underground power transmission. Steel pipes are commonly used in underground power transmission systems due to their durability, strength, and resistance to corrosion. They provide a protective casing for the power cables, ensuring their safety and preventing damage from external factors such as moisture, soil movements, and potential impacts. Steel pipes also allow for easy installation, maintenance, and repair of the power transmission system. Additionally, their ability to withstand high pressure and temperature makes them suitable for carrying the high voltage electricity required for power transmission. Overall, steel pipes are a reliable and efficient choice for underground power transmission.

- Q: What are the different types of valves used with steel pipes?

- There are several types of valves commonly used with steel pipes, including ball valves, gate valves, globe valves, check valves, and butterfly valves. These valves serve different purposes and have various designs, such as quarter-turn operation for ball valves, wedge-shaped gates for gate valves, and disc-shaped elements for butterfly valves. Each type of valve offers specific advantages and is selected based on the application requirements and the flow control needs of the steel pipe system.

- Q: How do you prevent steel pipes from freezing in cold climates?

- One way to prevent steel pipes from freezing in cold climates is by insulating them. Insulation materials such as foam or fiberglass can be wrapped around the pipes to prevent heat loss and keep them at a stable temperature. Additionally, using heat tape or cables can provide an extra layer of protection by applying low-level heat to the pipes. It is also important to ensure that pipes are properly sealed and any cracks or gaps are sealed to prevent cold air from entering and freezing the pipes.

- Q: What are the different types of steel pipe coatings?

- There are several types of steel pipe coatings, including epoxy coatings, polyethylene coatings, polyurethane coatings, and zinc coatings.

- Q: What is a tight steel tube?

- The fully enclosed steel tube is called "sleeve connection steel pipe". The English abbreviation is JDG. The sleeve between the pipe and the pipe is fastened by screws. The current specification is the construction and acceptance rules of CECS 120:2007 sleeve steel conduit pipe line

Send your message to us

Prime Galvanized Pipe full sizes for greenhouse frames/handrails

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords