High Quality Construction Pre-Galanized Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications of High Quality Construction Pre-Galvanized Pipe

Usage/Applications

To be used for conveying gas, water, and petroleum for oil and natural gas industries. And use for the structural steel pipes purpose.

Packaging/Delivery

Pipes will be bundled with 6-8 pieces and with steel strips. Delivery as per customer’s demands.

- Q: Can steel pipes be used for telecommunications cables?

- No, steel pipes cannot be used for telecommunications cables. Telecommunications cables are typically made of fiber optic or copper materials. Steel pipes are used for various applications in construction and plumbing, but they are not suitable for transmitting data or electrical signals. Fiber optic cables are designed to carry high-speed data over long distances, while copper cables are used for transmitting both data and electrical signals. These cables have specific insulation and shielding properties that steel pipes do not possess, making them unsuitable for telecommunications purposes.

- Q: What are the different coating materials used for steel pipes?

- Some common coating materials used for steel pipes include epoxy, polyethylene, polyurethane, and coal tar enamel. These coatings are applied to protect the steel from corrosion and provide a barrier against environmental elements.

- Q: What are the lengths of scaffold steel tubes?

- Scaffold tubes are our name for materials used to build scaffolding, because most scaffolding uses tubular bamboo or steel tubing. Bamboo and other bamboo is for a long time in the use of the scaffolding tube, but due to lack of safety and durability, now only in rural and urban area construction is lagging behind some of the home building small building has been used. The modernization construction, the most commonly used type of scaffolding pipe is steel pipe, the scaffolding should not only meet the demand of workers, but also to meet the characteristics of scaffolding firm and durable, so tough hard steel is the best choice. The selected steel pipe generally requires smooth surface, no cracks, no bending, no rust, and meet the relevant national standards.

- Q: What are the different types of steel pipes available?

- There are several types of steel pipes available, including seamless pipes, welded pipes, galvanized pipes, and stainless steel pipes.

- Q: What are the different types of fittings used with steel pipes?

- There are several different types of fittings that are commonly used with steel pipes. These fittings are designed to connect, control, or change the direction of flow in a piping system. Some of the different types of fittings used with steel pipes include: 1. Elbow fittings: These fittings are used to change the direction of flow in a piping system. They come in various angles, such as 45 degrees or 90 degrees, and are commonly used to navigate around obstacles or create bends in the pipe. 2. Tee fittings: Tee fittings are used to create a branch or split in a piping system. They have three openings, with one being perpendicular to the other two. This allows for the connection of two pipes at a 90-degree angle. 3. Coupling fittings: Couplings are used to connect two pipes of the same size together. They are usually threaded and can be easily tightened or removed using a wrench. Couplings are commonly used in applications where pipes need to be joined or repaired. 4. Reducer fittings: Reducers are used to connect pipes of different sizes together. They have one end that is larger in diameter and another end that is smaller. Reducers are often used to transition between pipe sizes or to adapt to different equipment or fittings. 5. Flange fittings: Flanges are used to connect pipes, valves, or other equipment to create a secure and leak-proof connection. They consist of a flat, circular plate with holes for bolts or screws to fasten the flange to the pipe. Flange fittings are commonly used in applications where frequent disassembly and reassembly is required. 6. Union fittings: Union fittings are used to join two pipes together in a manner that allows for easy disconnection. They consist of three parts: a nut, a female end, and a male end. Union fittings are often used in applications where periodic maintenance or repairs are necessary. 7. Cap fittings: Cap fittings are used to seal the end of a pipe. They are typically threaded and can be easily screwed onto the end of the pipe. Cap fittings are commonly used in applications where pipes need to be temporarily closed off or protected. These are just a few examples of the different types of fittings used with steel pipes. The specific type of fitting required will depend on the application, the size and material of the pipe, and the desired functionality of the piping system.

- Q: Are steel pipes more expensive than other types of pipes?

- The cost of steel pipes compared to other types of pipes can vary depending on various factors. Steel pipes are generally considered to be more expensive than some other types of pipes in terms of upfront cost. This is mainly due to the high cost of raw materials and the manufacturing process involved in producing steel pipes. Additionally, steel pipes are known for their durability and strength, making them a popular choice for applications where high pressure or extreme conditions are involved. However, when considering the long-term cost and benefits, steel pipes can often be more cost-effective. They have a longer lifespan compared to some other types of pipes, reducing the need for frequent repairs or replacements. Steel pipes also offer excellent resistance to corrosion, making them suitable for various environments and reducing maintenance costs over time. Moreover, the strength and durability of steel pipes can contribute to a lower risk of leaks or other failures, which can result in significant cost savings in terms of preventing damage or loss. It is important to consider the specific requirements and characteristics of the project or application when comparing the cost of steel pipes to other types of pipes. Factors such as the type of fluid or material being transported, the required pressure rating, the expected lifespan, and the environmental conditions should all be taken into account. Ultimately, while steel pipes may have a higher upfront cost, their long-term durability and reliability can often make them a cost-effective choice in many applications.

- Q: What is the difference between galvanized iron pipe and galvanized steel pipe? Or called different, in fact, is referred to as galvanized pipe?

- Just name different, all refers to GB/T 3091-2015 "low pressure fluid transport welding pipe" contained in the galvanized pipe.Galvanized pipe means zinc plated, suitable for water, air, heating, steam and gas and other low pressure fluid conveying straight welded steel pipe, longitudinal submerged arc welding (SAWL) steel pipe and spiral seam submerged arc welding (SAWH) steel pipe.

- Q: What is the maximum allowable pressure for steel pipes?

- The maximum allowable pressure for steel pipes typically depends on various factors such as the pipe's diameter, thickness, and material grade. Additionally, it is crucial to consider the intended application and the specific industry standards or codes being followed. Therefore, there is no universal answer to this question, as the maximum allowable pressure can vary significantly depending on these factors. It is essential to consult relevant codes and standards specific to the application to determine the appropriate maximum allowable pressure for steel pipes.

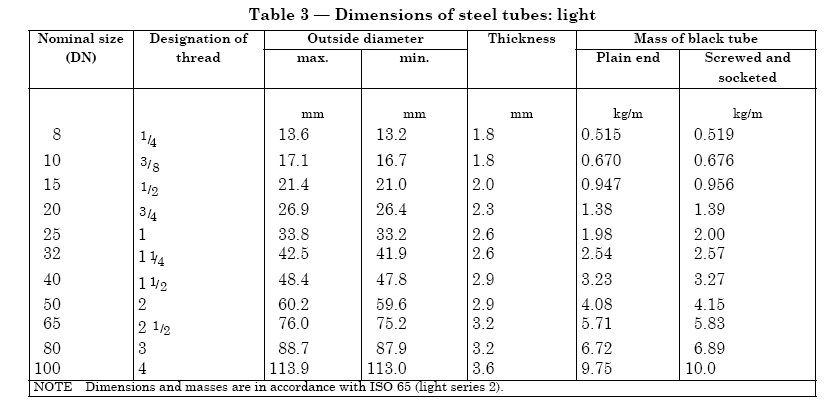

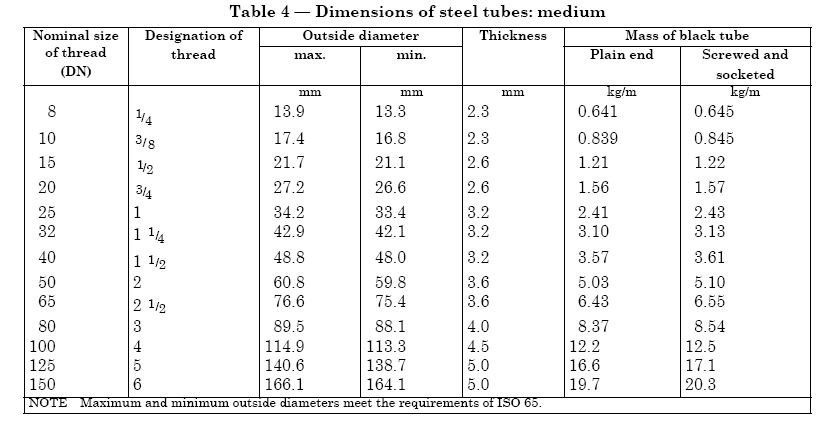

- Q: What are the dimensions of steel pipes?

- Steel pipes can have varying dimensions depending on specific requirements and industry standards. However, they generally adhere to standardized measurements for their outer diameter (OD), wall thickness, and length. The OD of steel pipes can range from small sizes, such as ¼ inch (6.35 mm) or ⅛ inch (3.175 mm), to larger sizes like 48 inches (1219.2 mm) or more for specialty applications. The wall thickness of steel pipes can also vary significantly, ranging from thin pipes with a few millimeters of thickness to thick pipes with several inches of thickness. Regarding length, standard steel pipes are typically produced in lengths of 20 feet (6.1 meters) or 40 feet (12.2 meters). However, custom lengths can also be manufactured to meet specific project requirements. It is important to note that these dimensions are only general examples and may not encompass all potential variations in steel pipe sizes. Therefore, consulting relevant industry standards and specifications is always recommended to determine the precise dimensions necessary for a specific application.

- Q: What kind of argon arc welding wire is used for 16Mn steel pipe?

- 16Mn steel weldability is very good, general use TIG with J50 welding wire, hand arc welding with J506, J507 and other welding rod

The main production and sale of galvanized steel, the thin-walled high-frequency welded pipe, galvanized pipe, square pipe, rectangular pipe, conduit, EMT conduit, greenhouse pipes, galvanized pipes, and other related products, annual production capacity of 40,000 tons. The company has independent export rights.

1. Manufacturer Overview

| Location | Tianjin ,China |

| Year Established | 2004 |

| Annual Output Value | Above 100milion rmb |

| Main Markets | Main land;Middle East;Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | 38000squar meter |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

High Quality Construction Pre-Galanized Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords