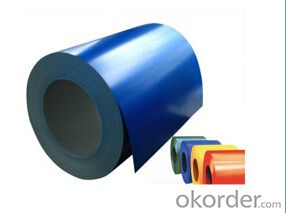

Prepainted Galvanized Steel Coils for Construstion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Model NO.:CGCC, JIS3312

Surface Treatment:Coated

Certification:ISO, SGS

Technique:Cold Rolled

Standard:ASTM, JIS, GB

Application:Construction, Roofing and So on

Edge:Slit edge

Stock:Stock

Steel Grade:Q195-235

Thickness:0.16-0.8mm

Width:800-1250mm

Color:Ral Number

Zinc:30G/M2-100G/M2

Coils Weight:3-5tons/Coils

Export Markets:Global

Additional Info.

Packing:Export Standard Packing

Standard:JIS G3312

Origin:Shandong Province, China

HS Code:72107000

Production Capacity:100000tons/Year

1. PPGI, prepainted galvanized steel coil(Annual Output: 200, 000tons)

(1). Leading manufacturer in China

(2). Competitive price

(3). High quality

(4). Good after-sale service

2. The Feature of PPGI:

1). Geade: CGCC, other grade can be available

2). The thickness range of the PPGI: 0.16mm to 0.8mm

Tolerance of thickness of The PPGI: +/-0.03mm

3). Width range: 800mm to 1250mm

Tolerance of width: +/-3.00mm (aiming to +/-2.00mm)

4). Zinc coating: Z40-Z275

5). Coil internal diameter: 508mm

6). Packing: Standard waterproof paper and galvanized steel protection cover and steel strip packed

7). Applications of PPGI: Widely used for roofs, outer walls, ovens, Explosive-proof steel, electrically controlled cabinets, and industrial freezers in the Residential and industrial buildings.

The detailed information:

Price termsFOB, CFR, CIF

Payment terms30%TT in advance+70% TT or irrevocable 70%L/C at sight

Delivery time25 days after recepit of 30% TT

RemarksInsurance is all risks

MTC will be handed on with shipping documents

We accept the third party certificatation test

CNBM, has supplied the best qualities to our clients in overseas and domestic markets, based on our credit, quality, accurate shipment and prompt action to meet all the requirements of clients. And now we have export to Korea, Europe, Africa,Egypt, Middle East, South Amarica market and so on.

We assure you that our good qualified products make our esteemed clients beneficial and satidfied on their demands.

Q&A

Acceptable payment term and way?

T/T,L/C, T/T + L/C, D/P

Acceptable price term?

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the qualitycontrol for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

What is your acceptable payment term?

TT,LC,OA etc

- Q: Steel used to be made in the #92;Bessemer Converter, write about how steel making processes today produce better quality steel????

- how we can prepared steel by using converter? ans it

- Q: How do steel coils contribute to the energy storage industry?

- The energy storage industry benefits greatly from the use of steel coils in multiple ways. Initially, steel coils are instrumental in the fabrication of energy storage systems like batteries. Through their steel casing, batteries are provided with both structural support and protection for the battery cells, ensuring their safety and longevity. If not for steel coils, batteries would be more susceptible to damage and unable to function efficiently. Furthermore, the construction of flywheels, an alternative form of energy storage technology, heavily relies on steel coils. Flywheels store energy by spinning a rotor at high speeds and releasing the stored energy when necessary. Steel coils are employed to create the rotor, which necessitates strength, durability, and the ability to withstand substantial rotational forces. Additionally, the magnetic properties of steel contribute to the enhancement of energy transfer efficiency within the flywheel system. Moreover, compressed air energy storage (CAES) systems also utilize steel coils in their production. CAES systems store energy by compressing air and releasing it to generate electricity upon demand. Steel coils are crucial in constructing the air storage chamber, guaranteeing its integrity and preventing any leakage or damage. The robust nature of steel coils makes them ideal for enduring the high pressures associated with the compression process. To summarize, the energy storage industry greatly benefits from the utilization of steel coils. They provide essential structural support, durability, and protection to various energy storage technologies, whether it be batteries, flywheels, or CAES systems. By contributing to the efficient and secure storage of energy, steel coils facilitate the advancement and adoption of sustainable energy solutions.

- Q: How can I arbitrate quality of steel before purchasing it??

- The quality of the alloy can be very well be judged by its appearance and lustrous surface. The more luster on the surface the more refine will the steel be. To judge its tenacity and endurance, the alloy can be subjected to a series of procedures involving stress and shock. The reaction to these processes can determine whether the steel be fit for the purpose required.

- Q: I worked REALLY HARD basically begged my dad to let me stretch my ear lobe piercings. He finally said yes, as long as I don't pass 2g. c: So, we went to Hot Topic to buy tapers, but I don't know if I should get Steel or Acrylic tapers. Which ones are better to start off with?

- steel because they dont get that infected also they sre easier to put in. but they do get cold in the winter

- Q: How are steel coils used in the production of shelving units?

- Steel coils are used in the production of shelving units by being cut and formed into various components, such as brackets and supports. These components are then assembled and welded together to create the frame and structure of the shelving unit. The steel coils provide strength and durability to the shelving units, ensuring they can withstand heavy loads and provide long-lasting storage solutions.

- Q: Can steel coils be coated with heat-resistant materials?

- Yes, steel coils can be coated with heat-resistant materials.

- Q: How are steel coils used in the manufacturing of industrial pumps?

- Steel coils are used in the manufacturing of industrial pumps as they are typically used to construct the pump housing and impellers, providing the necessary strength and durability for handling high-pressure fluids and withstanding harsh operating conditions. The steel coils are processed and shaped into various components, ensuring the structural integrity and reliability of the pump, ultimately contributing to its efficient operation and long lifespan.

- Q: What is the maximum temperature steel coils can withstand?

- The maximum temperature that steel coils can withstand varies depending on the specific grade and type of steel being used. Steel is known for its high heat resistance and can typically withstand temperatures ranging from 550°C to 1,100°C (1,022°F to 2,012°F), depending on the grade. However, it is important to note that prolonged exposure to high temperatures can cause steel to lose its structural integrity and result in permanent deformation or even failure. Therefore, it is crucial to adhere to the manufacturer's guidelines and specifications when determining the maximum temperature that steel coils can withstand in specific applications.

- Q: What are the different coil surface finishes?

- There are several different coil surface finishes, including mill finish, brushed finish, embossed finish, and coated finish.

- Q: How are steel coils used in the production of metal bridges?

- Steel coils are used in the production of metal bridges as they are rolled into the desired shape and size to form the structural components of the bridge, such as beams, girders, and support structures. These coils provide the necessary strength and durability to withstand the weight and stress of the bridge, ensuring its long-term stability and safety.

Send your message to us

Prepainted Galvanized Steel Coils for Construstion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords