Prepainted Galvanized Steel Coil High Zinc Coat

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Introduction of Prepainted Galvanized Steel Coil:

Galvanized steel coil is a special type of steel coil used in a number of different applications within fabrication and manufacturing environments. Steel coil of any kind is flat stock that is thin enough to be rolled into a coil or wound into a continuous roll.

2.Usages of Prepainted Galvanized Steel Coil:

Prepainted Galvanized Steel Coil is also able to be rolled out flat and cut at any length or shape needed. Having the steel coil galvanized helps the user by allowing it to be applied in outdoor fabrication projects.

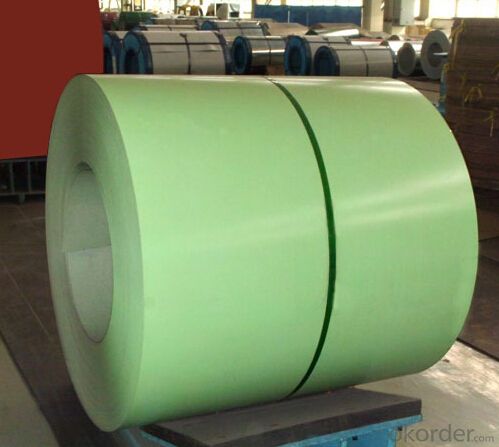

3.Prepainted Galvanized Steel Images:

4.Galvanized Steel Specification:

Base metal | Hot dipped galvanized steel |

Thickness | 0.16-0.8mm |

Width | 800-1250mm |

Coil Weight | 3-10 ton |

Quality: | SGCC, Dx51D |

Color | all RAL colors( standard international color) or customers samples color |

Zinc-coating | 60g/m2-180g/m2 |

Coil ID | 508mm, 610mm |

techinque | cold rolled, hot-dipped galvanizing, color coated |

painting | Top and bottom:20mic+5mic RMP Back:7mic-10mic |

Tolerance | Thickness:+/-0.02mm Width: +/-2mm |

feature | Pre-painted Steel Coils have excellent performance of decoration, corrosion resistance etc. |

5.Our Factory:

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the different methods of shearing steel coils?

- There are several different methods of shearing steel coils, each offering its own unique advantages and disadvantages. Some of the most common methods include: 1. Guillotine Shearing: This method involves using a guillotine-like machine with a blade that moves vertically to cut through the steel coil. Guillotine shearing offers high efficiency and accuracy, making it suitable for large-scale industrial production. However, it may cause deformation or burrs on the cut edges. 2. Rotary Shearing: In rotary shearing, a set of rotating blades is used to cut through the steel coil. This method allows for continuous cutting, making it ideal for high-speed production lines. It provides a clean and precise cut, but it requires regular maintenance and sharpening of the blades. 3. Slitting: Slitting involves passing the steel coil through a set of circular blades that make multiple parallel cuts. This method is commonly used to produce narrower strips from wider coils. It offers high precision and can produce multiple strips simultaneously. However, slitting may cause edge burrs or camber on the strips. 4. Laser Cutting: Laser cutting uses a high-powered laser beam to melt or vaporize the steel coil along a pre-determined path. This method offers exceptional precision and can cut complex shapes or patterns. It is commonly used for specialized applications where accuracy is crucial, although it can be relatively expensive. 5. Waterjet Cutting: Waterjet cutting utilizes a high-pressure stream of water mixed with abrasive particles to cut through the steel coil. This method is versatile and can handle various materials and thicknesses. It is especially useful for cutting heat-sensitive materials or for applications requiring minimal distortion. 6. Plasma Cutting: Plasma cutting involves ionizing a gas to create a plasma arc that melts and blows away the steel coil. This method is fast and efficient, suitable for cutting thick steel coils. However, it may produce a wider heat-affected zone compared to other methods. 7. Electrical Discharge Machining (EDM): EDM uses electrical discharges to erode the steel coil and create the desired shape. This method is commonly used for intricate or delicate cutting tasks that require high precision. It is particularly effective for hard materials. Each method of shearing steel coils has its own set of advantages and limitations, and the choice depends on factors such as the required precision, speed, material thickness, and the desired end-product.

- Q: How are steel coils loaded onto trucks or containers?

- Steel coils are typically loaded onto trucks or containers using specialized equipment such as cranes or forklifts. The coils are carefully lifted and positioned onto the truck or container bed, ensuring proper weight distribution and securing them with straps or chains to prevent any movement during transportation.

- Q: How are steel coils coated for corrosion resistance?

- Steel coils are typically coated for corrosion resistance using various methods such as hot-dip galvanizing, electroplating, or applying a protective layer of paint or powder coating.

- Q: Why?Which one should i get? I am just starting to learn Guitar. Which one would be better for me? What is the difference? I already got the acoustic nylon but i might return it... if the steel is better.

- A nylon string guitar, more properly called a classical guitar, is used almost exclusively for playing classical music. Unless you're interested in classical music you should avoid this guitar. Also, it is only played fingerstyle so you will not be able to learn how to use a pick, which is a valuable, necessary skill. Steel string acoustic guitars are used for a wide variety of music including rock, pop, folk, bluegrass, and more. This is a much more versatile guitar and is the one you probably should have bought.

- Q: How are steel coils processed for further use?

- Steel coils are typically processed for further use through a series of steps. First, the coils are uncoiled and fed into a machine that straightens and levels them. Then, the steel is cut into the desired length and width. Next, the edges are trimmed and any defects are removed. The coils are then cleaned, treated, and coated to enhance their corrosion resistance and appearance. Finally, the processed coils are either stored or transported to manufacturers who transform them into various products such as automotive parts, appliances, construction materials, and more.

- Q: Can steel coils be coated with heat-resistant materials?

- Yes, steel coils can be coated with heat-resistant materials.

- Q: How are steel coils used in the manufacturing of railway tracks?

- Steel coils are used in the manufacturing of railway tracks to produce high-quality and durable rails. These coils are unwound and undergo a series of processes such as rolling, heating, and shaping to form long, straight sections of rail tracks. The steel coils provide the necessary strength and flexibility required to withstand the heavy loads and constant stress of trains running on the tracks.

- Q: What are the different methods of joining steel coils?

- There are several methods of joining steel coils, including welding, mechanical fastening, adhesives, and interlocking systems. Welding involves fusing the ends of the coils together using heat or pressure. Mechanical fastening includes using bolts, screws, or other fasteners to hold the coils together. Adhesives can be used to bond the coils, providing a strong and durable connection. Interlocking systems involve designing the coils with special shapes or profiles that fit together, creating a secure joint.

- Q: What are the different grades of steel used for manufacturing coils?

- There are several grades of steel that are commonly used for manufacturing coils. These grades are chosen based on their specific properties and suitability for different applications. Some of the most common grades of steel used for manufacturing coils include: 1. Low carbon steel (mild steel): This grade of steel is often used for manufacturing coils as it is relatively inexpensive and has good formability. It is suitable for applications that require low strength and high ductility, such as automotive components and construction materials. 2. High carbon steel: This grade of steel is known for its high strength and hardness. It is commonly used for manufacturing coils that require high tensile strength, such as springs and wires. 3. Stainless steel: Stainless steel is a corrosion-resistant alloy that contains a high percentage of chromium. It is commonly used for manufacturing coils that require resistance to corrosion and oxidation, such as in the food industry, medical equipment, and automotive applications. 4. Galvanized steel: Galvanized steel is coated with a layer of zinc to protect it from corrosion. It is commonly used for manufacturing coils that will be exposed to harsh environmental conditions or for applications that require excellent durability, such as roofing materials and electrical appliances. 5. Alloy steel: Alloy steel is made by adding elements such as manganese, nickel, chromium, or molybdenum to carbon steel. This improves its strength, hardness, and resistance to wear and corrosion. Alloy steel coils are commonly used in applications that require high strength and toughness, such as in the aerospace and automotive industries. It is important to select the appropriate grade of steel based on the specific requirements of the application to ensure optimal performance and longevity of the coils.

- Q: Search the internet for 'Frost Clipper Knife'. This knife comes in either stainless or carbon steel. I have a friend who has one (stainless steel) and he is very impressed with it, but I have heard that Carbon Steel blades are better? Discuss...

- There are different grades of Carbon Steel. A good grade is much harder than Stainless Steel and will stay sharp longer. It is also many times harder to get an edge on than Stainless Steel. I have had both and prefer the Stainless Steel because eventually the Carbon Blade does get dull, and you will wear out a Whet Stone trying to put the edge back on it. The Stainless Steel holds an edge an acceptable amount of time and is easier to sharpen when the time comes. Putting either knife through a can opener sharpener will ruin the edge and make it almost impossible to put another edge on the knife. Look closely and determine the angel of the bevel, then lay the knife bevel flat on a good whet stone and try to take a thin slice off of the stone. Turn the knife over and do the other side so you keep the edge centered on the blade. Keep turning the knife over and taking thin slices until it is sharp. Dress with a good quality sharpening steel.

Send your message to us

Prepainted Galvanized Steel Coil High Zinc Coat

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords